old line. There are thinkers, talkers and people who take action.

Blog

old line. There are thinkers, talkers and people who take action.

I was asked to present a sling and rigging overview training course for helicopter rigging at the 2014 HAI Conference in Anaheim, California. It was an honor to present the program with Robert Libby, Advanced Helicopter Training, Inc. in a preconference educational program. Jeff Gordon, Southern California Edison also presented a brilliant program on the planning that should be involved in all helicopter rigging applications. Both Mr. Gordon and Mr. Libby commented that while helicopter rigging is an extremely important factor in any successful mission, it often is totally overlooked when compared with land based lifting operations. Helicopter lifting slings like any rigging device, when used improperly can result in injury or death. From an exposure perspective improper helicopter sling usage can result in more devastating consequences than land based, sling and rigging operations. Helicopter Long Lines are also used for Human External Cargo applications and there are increasingly more inherent risk factors when the “load” is not an inanimate object. Human External Cargo Lines will be used more frequently by utility companies that perform transmission line work as more cost effective work can be done from the air than from the ground. Helicopter Long Lines manufactured by Lift-It® feature the finest materials and the same heavy duty fabrication skills developed over thirty-five years which are required to manufacture Lifting Slings capable of carrying serious weight. A Helicopter Long Line rated at 1,000 Lbs. receives the same care and attention to detail as Slings rated at 100,000 Lbs. Responsibility for any amount of weight from a manufacturing and load handling perspective should be based upon destruction testing. We are seriously committed in our dedication to excellence and operate 75 ton and 300 ton, in house, test machines calibrated to ASTM E4 standards. All Lift-It® HEC Lines and Helicopter Long Lines are proof tested and certified. Lift-It® Helicopter Long Lines provide the greatest value for your long line purchasing dollar. Lift-It® Long Lines featuring robust Dyneema® SK-75 fiber, YKK® Zippers, Cordura® and Vinyl materials meeting the demanding needs of the helicopter rigging industry. In addition to the vast array of helicopter long lines, we offer a complete line of Helicopter cargo nets and helicopter barrel slings. Helicopter cargo nets must be square in shape and are available in many sizes, fabricated from webbing or rope. Helicopter barrel slings with a bottom support design feature provides for positive barrel engagement. An important safety consideration in the use of a helicopter lifting sling, helicopter cargo net or helicopter barrel sling is a pre-use inspection. There is zero tolerance for defects and even a minor tear in a non-load bearing component, such as a zippered, primary, secondary or weighted long line can have profound and devastating consequences. Some additional safety points to consider: Helicopter Long Line inspections must be thorough, systematic and non-compromising. The inspection process should involve visual and tactile (hand over hand) inspection techniques as some forms of damage are not always visibly apparent. The inspector must always act conservatively as residual rope strength can never be determined by visual or tactile inspection; it can only be determined by destruction testing. Do not use any Helicopter Long Line, helicopter Sling, Helicopter Cargo Net, Hardware or Sling Protection Device that appears to be damaged. If there is any doubt, do not use and remove from service for a manufacturer evaluation. The user is responsible for establishing an Inspection System that employs three levels of inspection: Initial, Frequent and Periodic. The system should also include a person responsible for the development and perpetuation of the inspection program which would include: Training, Procedures, Recordkeeping, Removal from Service Criteria, Scheduling and Maintenance of the Inspection Records. Inspect the entire length of all Helicopter Long Lines for damage including splices. Ensure Eye Splices securely captivate thimbles and that Lockstitch Thread and Whipping Thread is not damaged or broken. Make sure Eye Splices are correct, have not slipped and do not display surface abrasion or cuts. Also inspect the Leg Junction to ensure it does not display cut or jagged strands. Both outer and inner rope fibers contribute to the strength of a Helicopter Long Line. When either is worn, the rope is weakened. Heavy use will cause the rope to be compacted or hard. This is an indication that rope tensile strength has been reduced. UV degradation is indicated by discoloration and the presence of splinters and slivers on the rope surface.

beam and rigging, he suggested that they purchase the rigging and RENT the spreader bar.

nuclear generation facility. The Lift-It family has had a long and honorable history

with the good people at PVNGS.

Many take distressed slings and use them for tiebacks to secure crane blocks and headache balls to the equipment during transport. The safety professionals at PVNGS took excellence to a higher level reasoning that distressed slings should not be used for any application. They had dedicated, polyester roundslings manufactured and labeled specifically for this application.

AEP – DC Cook Gets the Lead Out

The professionals at AEP, DC Cook took a proactive approach and

did more than talk about a problem. The collaboration with the design and

fabrication team at Lift-It Manufacturing resulted in a custom, Lead Blanket

Cart (Model No. LMC100355-755) capable of handling 4000 Lbs. The Cart

has usable inside width dimensions of 27.75″ and usable interior length

dimensions of 48 inches. Custom sizes and capacities are readily available.

We are honored to announce the collaboration between Van Beest and Lift-It® Manufacturing.

Lift-It® is the west coast, master distributor for Van Beest. Without substituting quality for cost, the Green Pin® brand has earned a reputation as an industry leader in design and quality standards. Compliant with a wide range of internationally and nationally recognized standards such as RR-C-271, all Van Beest products carry a “metric” or long ton rating.

What does all this mean? Lower cost, extremely short lead times and great quality! We carry a range of sizes and different types of rigging hardware listed below:

• 1/2″- 3-1/2″ – 120 Ton Bolt Type Shackles

• 1/4″ – 2-1/2″ – 55 Ton Screw Pin Shackles

• 40 – 200 Ton Wide Body Shackles

• 2 ½”-2 ¾” Jaw & Jaw Turnbuckles

Call today and your order ships the same day!

Effective rigger training like all training must do much more than simply provide information. Rigger training that does not result in changed behavior will not improve safety by reducing accidents. Long before industrial training was fashionable I began developing sling and rigging training which continues to evolve with each and every training session.

Based upon the feedback we receive from corporate, association and industrial training clients we know that passion and conviction play incredible roles in modifying dangerous behavior resulting in accident prevention.

Effective rigger training must challenge the attendee to examine their learned behavior and compare it with a benchmark. I believe in my message and my conviction certainly assists in getting those I train to consider the importance of their actions and the inevitable results. If your message is not compelling, singularly, passion will not yield a bountiful harvest. The plan is a simple one, we present the ideal, ask our students to examine their practices, determine the gap and prosecute our efforts to bridge the gap.

The goal of all rigger training should be to change perspectives and attitudes, one by one, resulting in behavior modification as an aversion to risky behavior is cultivated. If the trainer does not accomplish this then the activity is nothing more than window dressing whereby hindquarters are covered.

There is nothing like the satisfaction I receive when my students tell me that they have been rigging for many years and that they truly benefited from my lesson plan. This result is not easily achieved and requires a tremendous amount of development, practice, presentation and evaluation time. After thirty two years of practice I continue to adapt me course material beyond the necessary changes resulting from technological advances and regulatory updates.

At the ripe, old age of twenty-six I began my industrial training career and presented sling and rigging classes for an aerospace company and a crane repair facility. The preparation put into making these engagements successful paid off tremendously when I arrived early to set up for what would be one of the largest audiences I have ever addressed in a massive hotel ballroom located nearby the Los Angeles International Airport.

Long before training was fashionable I would present at any location, sometimes around the clock for anyone that would listen. Bruce McConnel and I did five continuous days of on-site training at the Phelps Dodge-Silver City, NM location and charged nothing. Based upon shift schedule we alternated with one hour presentations over a 16 hour period and provided an overview of wire and synthetic sling usage for several hundred miners. The master mechanic did visit the safety office and express his gratitude. Those that train know that presenting four- sixty minute presentations in a single day is a tenuous task. Forty presentations over a five day period would make water boarding seem like a church social!

The well-being of sling users truly is a passion that I have always had and it was further reinforced by the first sling fatality when one of our slings, badly damaged and not inspected prior to use, snapped and killed a Rodney Armstrong Guy, a 32 year old lineman.

You can judge a person’s passion by asking them one simple question. Would you do, what you do for free, assuming all your basic needs were already met? I can honestly and unreservedly say YES.

The Lift-It Learning Center is a dream come true. Regularly scheduled, safety training classes such as Crane and Rigging Training for the Competent and Qualified Person are presented. In addition, to Sling User, Basic Rigging Training and Sling Inspection Training, class for Harrington Hoist Inspection are also offered.

Just a few weeks back we presented at a corporate event in Las Vegas and a day later at a large association meeting in San Diego. The excitement of changing lives and making them better with enthusiastic industrial sling and rigging training has not waned, but has actually become more intensified as I continually improve and perfect a lesson plan that has been called life altering.

Michael J. Gelskey, Sr.

Wire rope slings have been the backbone of the sling and rigging industry for many years. Industrial lifting, crane and rigging companies have successfully used wire rope slings for many different applications. Even with the advent of synthetic slings in the early 1970’s, wire rope slings continue to have a place in rigging lofts worldwide.

It is important to know how to select a wire rope sling for a particular application. Initially wire rope slings were “hand spliced” and some may still use hand spliced wire slings. It is well known that rotation of the load can cause a hand spliced wire rope sling to come undone resulting in a dangerous situation.

Wire rope slings with mechanical spliced, Flemish eyes are a much better sling than a hand spliced sling.

If is also important to expose sling users to wire rope sling education. It never ceases to amaze me how many riggers, who use wire rope slings daily do not know or understand D/d ratio and the effect it has on wire rope sling efficiency. “D” (the diameter of the object you rig around) divided by “d” (the diameter of the wire rope sling) play an important part in determining overall sling capacity.

A 25/1 D/d ratio provides the sling user with 100% sling efficiency. In other words, if one rigs around a 25 inch diameter pipe with a 1 inch wire rope sling at a 90 degree basket hitch configuration, the sling user can use the sling at the 90 degree, basket work load limit as indicated on the sling tag. Conversely if the same, 1 inch diameter wire rope sling is rigged around a 4 inch diameter steel pipe resulting in a 4/1 D/d that same sling would have to be downgraded by 25% and would only have 75% of the rated, 90 degree basket work load limit.

Wire rope sling education should also inform the sling user of the differences in constructions, designs and materials. Braided wire rope slings, single body slings, multiple leg wire rope slings, strand laid grommets, swage socket assemblies all need to be used properly and inspected by competent inspectors, who have attended competent sling and rigging hardware training.

Even the core of the wire rope has profound implications for sling users and their safety.

Wire rope slings fabricated with Independent Wire Rope Cores (IWRC) have a higher temperature limit than slings fabricated with Fiber Cores (FC). Wire rope slings with fiber cores cannot be used at temperatures exceeding 180 degrees Fahrenheit. Wire rope slings with independent wire rope cores can be used at temperatures not exceeding 400 degrees Fahrenheit.

Some wire rope sling users believe that wire rope slings are cut-proof. This is also where wire rope sling education has to provide the basis for a correct perspective. Anything, even diamonds can be cut when tension and compression join forces. The ASME B30.9 sling safety standard states, “wire rope slings should be protected from damage by materials of sufficient strength, thickness and construction.”

If you have any questions, feel free to contact the sales professionals at Lift-It Manufacturing. We will assist you in determining how to order the correct sling for your application. Our Rigging Resource Guide contains a wealth of information on the selection, use and inspection of wire rope slings, chain slings, metal mesh slings, web slings and roundslings.

I presented the details of a fatality resulting from improper sling usage for the Associated Wire Rope Fabricators at their October 2013 meeting in Los Angeles. My presentation followed Todd Peterson, an attorney, who presented the events surrounding a serious injury that occurred in Omaha, Nebraska. The economic impact from injury is generally more of a serious consequence to a manufacturer than a fatality.

I began my career in the rigging industry at the ripe old age of seventeen. Seven years later I founded Lift-It Manufacturing. My training career began when I was twenty-six and I have been “practicing” for the past thirty-three years to perfect a message that will educate, inspire and challenge my students to adopt a quest for excellence that does not allow compromise.

My objective in the presentation for AWRF was to inform our association members of the specific details involved in this fatality to assist them in future safety and sales presentations. Some consider safety and product sales to be mutually exclusive, but this is not necessarily true.

It was during one of my training missions in northern Montana that I was informed that Rodney A. Guy, a thirty-two year old lineman was killed while using a sling made in our factory on March 20, 1992 at 2:15 PM. He and his crew were working in Rio Vista, CA on high power transmission lines and were in the final stages of the job.

I called the subcontractor who employed Mr. Guy and was told that the sling had failed exactly at the sling midpoint and the failure had occurred in a straight line. It was confirmed by the Accident Review Board that the sling had been previously damaged and was not inspected before use. In addition, the sling was overloaded and was degraded by ultraviolet ray degradation. In this instance and in many others generally it is not a single factor, but many factors which combine and lead to the death, injury and destruction.

As rigging professionals it is our duty to provide products and information that will enable our customers to effectively and efficiently accomplish their objective. Sales and safety are companions as true professionals will not only promote slings, but will also provide adequate sling protection.

It is disappointing when my training clients are amazed at the selection of protection devices that we and other progressive companies offer. It becomes readily apparent that the supplier servicing the training client is either uninformed or too busy to educate and provide information on sling protection devices.

All slings are susceptible to damage, synthetic slings are particularly vulnerable as they are not as robust as chain, wire rope or metal mesh slings. Two slings were used at the time of Rodney’s death. The unbroken sling had extensive damage and based upon the failure mode of our sling it had also been damaged in a similar manner. Adequate protection would have prevented this damage from occurring.

It is extremely important for sales and safety professionals, as well as for sling users to realize that sling protection must be of sufficient strength, thickness and construction to prevent damage and that the edge need not be “razor” sharp to result in damage to the protection and/or the sling.

Gloves, cardboard and makeshift devices are generally not effective. Some companies provide sling protectors which have been tested and labelled, providing the user with the cut resistance capabilities of the protection devices. This is very redemptive as the user is not tasked with determining adequacy.

Sling inspection is also critically important to ensure safe usage. If any one of the four men on March 20, 1992 had inspected the sling and had been trained to detect damage, the sling would not have been used. The cost of the sling was $40.00 and our dealer, Cable/Cisco in West Sacramento, which is forty miles from the fatality site, had similar slings in stock. Forty dollars and forty miles would have been all that was needed to prevent this terrible tragedy.

In addition, both slings were severely degraded by ultraviolet light. They were once bright yellow and vibrant in color. Photos taken at the time of the incident depict slings which are faded and gray. When slings are not in use they should be stored in a cool, dark, dry location which is free from mechanical or environmental damage. The principle is a simple one: If you take care of your rigging, your rigging will take care of you.

I challenged those in attendance at my presentations to become vigilant in the promotion of adequate sling protection. I challenge my students to view their sling storage locations and ask one question. The slings are plentiful, but where’s the protection? “You can’t have one without the other, it’s like a hand in a glove, like bread and butter!” Cute rhyme that helps sling users remember to always have protection alongside their slings!

Even after hundreds of presentations done over the past thirty-three years I still do not sleep well the night before the presentation. I’m excited about the upcoming training, the people I will meet and lives that I will impact. It’s a numbers game and nothing good comes from a person dying, other than to use their example to scare others alive. There is no way of knowing how many lives Rodney has saved by dying, but those who have met him through me, owe Mr. Guy and his family a tremendous debt of gratitude.

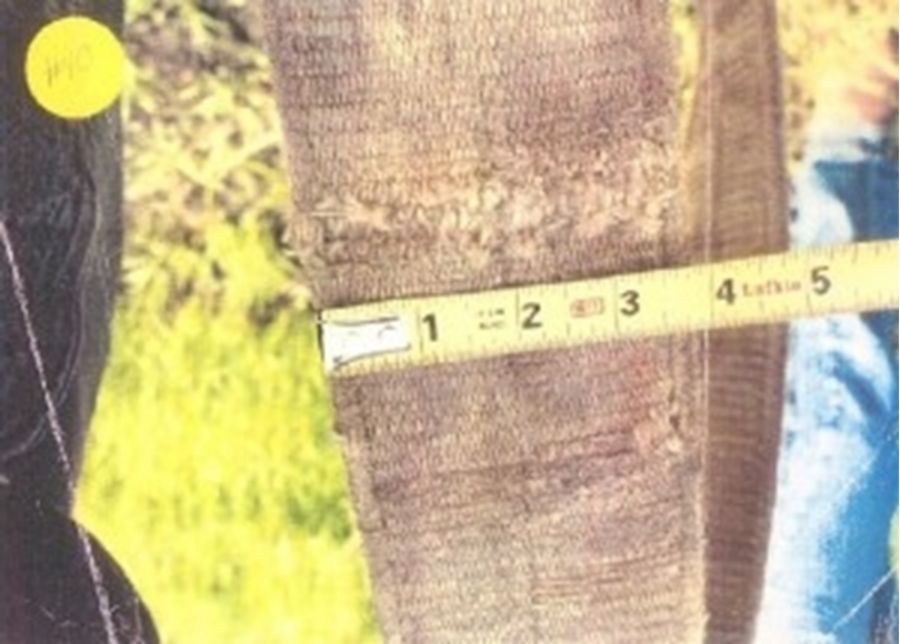

(Please note the sling in the background and the evident damage. This is the sling that killed Rodney!)

Mike Gelskey Sr., CEO of Lift-It Manufacturing is featured on the American Wire Rope Fabricators (AWRF) website. Mr. Gelskey is featured in a educational article regarding "Sling Safety Training-The Right Perspective." Mr. Gelskey, has been serving the rigging industry for over 40 years. He recently presented the details of a fatality resulting from improper sling usage for the Associated Wire Rope Fabricators at their October 2013 meeting in Los Angeles. To read the article in its entirety and to learn more about sling safety training and the mission Mr. Gelskey and the team at Lift-It is on please click through to the AWRF article by clicking here.

Chain slings are one of the most durable and robust types of rigging available. It is not uncommon to inspect chain slings that have been in service up to 40 years. Industrial lifting slings fabricated from chain offer riggers two important advantages over nylon web slings, polyester round slings and twin-path® slings: wire chain slings are more temperature tolerant, cut resistant and certain options allow chain rigging slings to be adjustable.

Chain is produced in different grades. The larger the lifting chain grade number, the stronger the rigging chain. Grade 30 and 40 chain is sold at many hardware stores and is great for barricading parking lots or defending yourself, but shall NEVER be used for lifting chains. Grade 70 transport chains used by trucking and transportation companies are acceptable for use as tie down chains to tie down loads, but shall NEVER be used for rigging chain lifting slings. The only grades of rigging chain that is acceptable for lifting (not overhead lifting, as you are never on, under, near or next to the load or any rigging that is under tension) are grade 80 lifting chain, grade 100 lifting chain and grade 120 rigging chain. The metal used in Grade 80, 100 and 120 crane rigging slings is designed to stretch and elongate. This is a very important reason for close attention to detail when measuring chain slings during the annual inspection. Up to a few years ago the most common grade of alloy lifting chain used for crane chain slings was grade 80. Recently, most major rigging chain manufacturers are shifting to grade 100 lifting chain, which size for size is stronger and lighter than grade 80 rigging chain. The lifting chain used in the fabrication of your rigging chain slings is quenched and tempered in the wire chain fabrication process. The Chain rigging slings we make and supply meets or exceeds the recommended standards of the National Association of Chain Manufacturers (NACM), ANSI/ASME B30.9 standards and DOL-OSHA regulations.

There are many different type of chain sling fittings that enable the users of industrial lifting slings fabricated from chain access to single leg chain slings, double leg chain slings (also known as two leg chain slings), triple leg chain slings (also known as three leg chain sling bridles) and quad leg chain slings (also known as four legged rigging chain sling bridles). In addition to standard chain sling fittings, custom made fittings and custom made lifting chains are readily available.

Standards that govern the manufacture of chain lifting slings require that either the final assembly or all the individual components used to fabricate rigging chains must be proof tested and certified. We proof test every chain sling we manufacture and provide you with a certificate of test. We do not charge extra for this service.

We are proud to offer the Gunnebo, GrabiQ line of chain rigging slings in addition to wide range of standard industrial lifting chain slings. The GrabiQ chain sling system is simpler and smarter! Instead of the conventional approach where one fitting does on job, GrabiQ crane chain slings and chain sling bridles combine up to three separate functions into a single component. A GrabiQ two leg adjustable chain sling would have ONLY three fittings. The GrabiQ, master grab serves with built in adjustment hooks, serves as a master link, a connector for the rigging chain sling legs and also allows adjustment for the chain sling legs, IN ONE FITTING. To put it into perspective, a GrabiQ double leg adjustable rigging chain sling bridle has a total of ONE fitting. A conventional, double leg adjustable chain sling bridle would have SEVEN fittings. The difference is even more dramatic when you consider the same comparison for a four leg adjustable chain sling bridle. A GrabiQ four leg adjustable rigging chain sling bridle has a total of THREE fittings. A normal double leg adjustable chain crane sling bridle would have THIRTEEN fittings. To view the radical difference, see page 170 in our Resource Guide.

Anyone given the choice, would automatically opt for the GrabiQ lifting chain sling by answering two questions:

Which chain sling bridle is lighter? Which rigging chain bridle sling is easier to inspect?

There are many unique fittings that make up the GrabiQ chain sling system. Top fittings are: Master Grab (MG) for single leg sling rigging chains and Master Grab Dual (MGD) for two lifting chain leg slings. The Master Grab and Master Grab Dual combine master link, connector and shortening functions into one fitting. Oblong master links (MF) can be used for 1, 2, 3 or 4 leg chain slings when C-Grab or C-Lok lifting chain sling connectors are used. Oblong master links (MFX) can be used as the top connector for 1 leg or 2 leg chain sling assemblies when used with C-Grab or C-Lok connectors. The oversized masterlink with sublink (MTX) is used as the top connector for 3 leg or 4 leg chain sling assemblies with C-Grab or C-Lok connectors.

GraiQ connector components are used with MF, MFX or MTX master links to form up chain sling bridle assemblies.

The GrabiQ C-Grab (CG) is used as a connection to a masterlink for a single leg chain sling and can also be used as a sliding choker hook. The C-Grab has a built in chain pocket for shortening or creating leg loops. The GrabiQ C-Grab Dual (CGD) functions like the C-Grab, except it connects two legs of lifting chain to the MF, MFX or MTX masterlinks. C-Lok (CL) hooks are used with the GrabiQ masterlinks to attach one leg of chain and can also be used as a sliding choker hook.

C-Lok Dual (CDL) is a GrabiQ connector link used to attach two legs of crane chain sling to GrabiQ master links.

GrabiQ hooks are also readily available as the fitting that connects the chain sling to the load. EGKN sling hooks are one of the most popular fittings. The GBK self-locking hook features a protected grip latch that locks in the hook point.

GrabiQ swivel hooks are also available. LBK Swivel eye features a grip latch and a bushing that allows hook rotation BEFORE the load is applied. The LKBK swivel eye grip latch hook has a ball bearing that allows the hook to swivel under load. The EGKN GrabiQ clevis sling hook is also a very popular chain rigging sling hook.

GrabiQ top assemblies are available for non-adjustable and adjustable rigging chain sling assemblies. Top L Top Lok (TL1) is for single leg or 1 leg chain rigging slings that are not adjustable. (TL2) is for double leg or 2 leg crane chain slings that are not adjustable. Top Lok (TL3) is for triple leg or 3 leg chain rigging slings that are not adjustable. Top Lok (TL4) is for quadruple leg or 4 leg chain slings that are not adjustable. If adjustable chain sling bridles are desired, GrabiQ Top Grab assemblies can be used. Top Grab (TG1) is for single leg or 1 leg wire chain slings that are fully adjustable. Top Grab (TG2) is for double leg or 2 leg lifting chain slings that are fully adjustable. Top Grab (TG3) is for triple leg or 3 leg rigging chain slings that are fully adjustable. Top Grab (TG4) is for quadruple leg or 4 leg chain crane slings that are fully adjustable.

GrabiQ components also enable the use of single basket chain slings and double basket chain sling assemblies that are non-adjustable, adjustable from one side and/or adjustable from both sides. The BS single basket chain sling is not adjustable. GrabiQ BSG single basket chain sling assemblies are adjustable from one side. The single basket type BSGG is a single leg basket sling that is adjustable from each side. Double basket chain sling assemblies are available as a non-adjustable chain sling Double Basket (DB). For a double basket chain sling that is adjustable from one side, specify:Model BDG. For additional versatility, the double leg basket chain sling is adjustable from either side.

GrabiQ MIG Midgrab shorteners are another innovative way to adjust the length of chain sling legs. The midgrab shortener can instantly positioned on any part of the chain sling leg or set idle when not in use. For a visual overview of the more popular GrabiQ chain sling assemblies see page 174 in our Resource Guide.

Chain slings that utilize standard chain sling fittings and components are also readily available. Single leg chain slings and chain slings with 2, 3 or 4 legs are manufactured and proof tested at Lift-It Manufacturing. It is important for you to consider if you require a non-adjustable lifting chain sling or an adjustable rigging chain sling bridle. Master links and masterlinks with subassemblies are used as top lifting fixtures. Alloy coupling links and chain sling couplers similar to hammerloks and lok-a-loy coupling links are used to connect the lifting chain sling legs to the oblong, top link. A vast selection of chain sling hooks is available to fit most every application. We can provide custom made fittings as components in custom made chain sling bridles. Sling hooks with half links, eye sling hooks with recessed latches, foundry hooks, eye grab hooks, clevis grab hooks and sliding choker hooks for chain slings are stocked for the immediate shipment of your wire chain bridles and chain sling assemblies. Eye type self-locking hooks with grip latches and eye type self-locking hooks with bronze bushings allow for the hook to rotate while under load are also readily available. Some applications require an alloy weld on hook. Alloy weld on hooks are available from 3/4 ton to 15 ton capacities.

For a complete overview of the most popular lifting chain sling and assemblies in single leg, double leg, triple leg and quad leg designs see pages 185-186-187-188 in our Resource Guide. You will also see Endless Basket Slings and Double Endless Basket Slings, as well as adjustable and non-adjustable chain rigging slings.

Another novel approach to adjustable chain slings comes in the form of a Slingmax® chain sling saddle ring. Chain sling saddle rings provide quick adjustment and are more economical, lighter and more versatile than conventional adjustable chain sling assemblies. Single slot rings are used for single leg and double leg lifting chain sling configurations. The double slot chain saddle ring is used for triple and quad leg rigging chain slings.

It is important to realize that chain slings can be damaged and can fail resulting in injury, death and/or property damage. It is extremely important that sling users are trained in proper use and inspection techniques. We offer training opportunities at our Learning Center in Pomona, CA on a monthly basis and encourage all sling users to read and understand the warnings that accompany all our rigging gear, hoisting equipment and/or industrial lifting slings.

We take great pride in making available to you, AT NO CHARGE, the most complete and descriptive Rigging Resource Guide available. Several thousands of hours were spent creating it and many more tens of thousands of dollars were spent printing it. At nearly 4 Lbs. it costs an additional $5.00 to mail you a printed copy. You can download a copy from our web site. Our Rigging Resource Guide contains hundreds of pages of general and safety information for the users of nylon web slings, chain slings, polyester round slings, Twin-Path® high performance fiber slings, metal mesh slings, wire rope slings, hoists, shackles, swivel hoist rings, nets, tool bags, rope, fall prevention equipment, plate clamps, blocks and material handling equipment like spreader bars and lifting beams. Compare the multiple warning pages in the chain sling section and ask yourself one question, “Who do you really want making your heavy duty, industrial lifting slings?” Our table of contents section is larger than others entire catalog. Contact us at 800.377-5438 for a copy of the Lift-It Rigging Resource guide.

Sling Chain Pricing

The steel market is a very volatile market for materials and therefore doesn’t allow us to add pricing to all our sling listings like the nylon slings, polyester round slings, or wire rope slings. Call our sales staff and we can provide you with the specification and pricing for your rigging slings. We can offer fixed pricing for an extended time. Please call toll free at 800-660-3585 and we will be happy to assist you.

Our chain slings are custom made to meet your specifications, therefore all chain slings are non-returnable.

Lifting Chains & Rigging Chain Configurations

Single Leg Chain Sling

A length of chain with fittings on each end used for lifting in a vertical hitch. This sling chain can be combined with unlimited fittings to suit your application.

Double Leg Chain Sling

Two single leg chain slings joined by an oblong at the top. This lifting chain is rated for both legs to be used simultaneously at a 60 degree angle.

3 Leg Chain Sling

Three single leg chain slings joined by a special oblong sub-assembly at the top of the lifting chains. Rated for lifting when legs are at 60 degree angles from the object.

4 Leg Chain Sling

Four single leg chain sling assemblies joined by a sub-assembly at the top of the rigging chain. Rated to lift using all 4 legs at 60 degree angles.

Basket Slings

This lifting chain is a loop of chain with both ends connected by an oblong at the top. This rigging chain is used to loop under the object to cradle and lift like a “basket”.

Double Basket Sling

Two loops of chain with all four sling chain ends connected attached to an oblong. Used to cradle a load with the sling loops spread apart for additional balance.

Single Adjustable Chain Sling

An overhead lifting chain with one single leg sling and an additional shorter leg with a grab hook. This allows you to slide the longer lifting chain’s links into the grab hook to shorten the length when needed.

Double Adjustable Chain Sling

This double leg chain sling has two additional shorter legs with grab hooks. Links from the longer sling chain can slide into the grab hooks to adjust the primary lifting chains to the appopriate length for your load.

Endless Basket Sling

An endless loop of chain with an oblong through it allowing that allows the lfting chain to rotate through the oblong freely.

Double Endless Basket Sling

Two endless loops of chain connected at the top of the overhead lifting chain assembly by an oblong. Chain moves freely through the oblong but allows for better load balance across the two legs.

Endless Chain

Simply an endless loop of chain used for lifting. No oblong is included.

Sling Hooks

Slip Sling Hook

A large throat hook used primarily at the ends of wire rope and chain slings. Usually self-locking to avoid disconnect.

Grab Sling Hook

A small throat hook that attached to the chain by sliding over the chain inbetween links. This hook locks into place by ‘grabbing’ the chain and will not slide along the chain.

Foundry Hooks

An EXTRA large throat hook used in unique situations that require a larger opening to manage loads.

Self-Locking Sling Hook

A self locking sling hook actually pivots in the middle and locks when lifting pressure is applied. This hook cannot be opened while unit is lifted with your overhead lifting chains.

Oblong Master Link

The oblong master link is an oblong shaped ring used at the top of wire rope and chain slings.

Bridle slings made from polyester and nylon web slings are a great device for handling loads with fixed lifting points.

Bridle slings are also referred to as Multi-leg Bridle slings, Bridle assemblies, Sling Bridle assemblies, Hardware Bridle slings, Web Sling Bridles or type 10 slings.

Any Bridle sling features three component parts: a top lifting fixture, connector fittings at the bottom and web straps that join the top lifting fixture to the bottom connection points. Most of the bridle slings we manufacture for the crane and rigging industry feature an oblong style master link. Another very viable option is the master link with sub-assemblies. The master link with sub-assemblies is particularly advantageous for bridle sling assemblies that feature more than two or three legs (depending upon the connection point width). Nylon web sling legs can be eye and eye or an endless configuration lifting sling. A big advantage endless nylon web slings have over Eye & Eye lifting slings is that connection and load points can be rotated. We also offer a complete line of polyester roundsling bridle assemblies which are strictly endless in configuration. The bottom connection point to the load for web sling bridles can be done by attaching rigging hooks or master links. Likewise anchor shackles or fabric eyes can also be supplied.

Nylon web sling bridles are inherently lighter and easier to use than chain sling bridles or wire rope sling bridles.

Web Sling bridles can be made in single leg sling, double leg bridle sling, triple leg bridle sling or four leg bridle sling designs. Recently, we were tasked with providing a custom bridle sling assembly for a large nuclear facility which had EIGHT legs. In this design we featured a 2-1/2 inch master link with sub-assemblies and legs made from polyester round slings. Custom made sling assemblies are done on a regular basis at Lift-It Manufacturing. Another good example of a custom web sling is the Tool bag bridle sling used by the wind power and generation industry to connect a lift line to the tool bag.

Nylon web sling bridle capacities are based upon many factors. Some, but not all are:

1) Web sling bridle legs are the same length.

2) Nylon sling bridle legs are attached at the same horizontal plane.

3) The center of gravity is equidistant from the lifting slings that make up the bridle assembly.

4) The sling to load angle is the same for all the nylon strap legs.

For more information on the effects of sling to load angle please refer to the Lift-It Resource Guide

If conditions other than these apply, a qualified person must determine the specific requirements and select a bridle sling assembly with suitable characteristics for the application.

Webbing sling bridles have taken on wide popularity of use in recent years and we have always provided web sling bridles that go above and beyond minimum strength requirements. Other important design characteristics must be taken into consideration. A picture is worth a thousand words, so please view a real life example of great bridle slings and bridle slings that are just flat ugly. Details are available by viewing page 66 in the Lift-It Resource Guide

The Lift-It web sling bridle mentioned in the link above features a 2 inch diameter master link. Brand ”X” used a 1-1/2 inch Crosby master link. The Crosby master link is certainly strong enough to support the four nylon lifting sling legs, each of which has a vertical capacity of 11,400 pounds. The problem is obvious; the oblong master link is too small. When you combine the undersized link with the way the eyes were tapered in the Brand “X” bridle assembly, the less than desirable effects are magnified. The Lift-It web sling bridle features sling eyes that are tapered to 1-1/2 inches in width. You’ll also notice the eyes in the Lift-It Bridle assembly are protected at the bearing point of the eye and eye slings. Brand “X” folded the 4 inch material in half to save time and maximize his profit margins, resulting in sling eyes that are 2 inches wide. Brand “X” also did not attach protection to the bearing points of the nylon straps.

Simply stated the Brand “X” bridle is not just bad, it’s ugly and typifies an old expression, “Putting 10 pounds of stuff into a 7 pound bag!”

Not only does the Lift-It nylon web sling bridle feature larger, more expensive hardware, but it is rated at LESS than the Brand “X” web strap bridle. Many manufacturers of nylon lifting sling bridles rate their four leg bridle sling assemblies by counting the strength of all four web sling legs. There is nothing patently wrong with this practice from a regulatory or recommended standards perspective. The rating for a Lift-It Four Leg Bridle sling is based upon THREE legs, not four. Some may say that we are overly cautious; others have said we’re “different”. When your safety is at stake, we’re happy to take the heat and the criticism. We have always believed that quality conscious web sling and rigging products users and purchasers, if educated will see our perspective.

When ordering Web bridle slings, the length of the lifting sling bridle is specified as reach, which is the distance between the bearing points of the top oblong master link to the connection point on the bottom of the web sling leg. Consider using Web sling hooks instead of regular hoist hooks. Web sling hooks made by Crosby feature a “Flat-Straight” bearing surface for the web strap. Hoist hooks have a round bearing surface that reduces nylon lifting sling efficiency as the web sling or polyester round sling bunches up on the diameter of the rigging hook eye. You probably have already surmised that when we supply the regular hoist hooks as connector for our web sling bridles that they are oversized to compensate for the bunching that occurs and you are absolutely correct in your assumption.

- 2023

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012