|

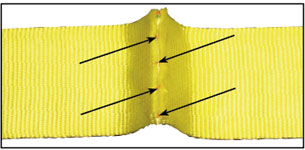

Four, identical, single ply slings were fabricated from a single roll of webbing. All independent variables were controlled, as the same thread, machine and fabricator were used for this experiment. The slings (EE1-903) are rated at 4800 Lbs. vertical and we would expect 24,000 Lbs. break strength. The slings were pulled to destruction. The control sling broke at 26,050 Lbs. The other three slings were deliberately cut on one edge to simulate: 1/8 inch, 1/4 inch and 3/8 inch cuts. This seemingly “minor” damage resulted in very significant strength loss.

“Minor” damage is extremely serious and damaged slings must be removed from service, immediately and not used for other applications. Remember, there is ZERO tolerance for sling damage. Be pro-active and prevent sling damage from occurring by employing suitable Sling Protection.

|

Sling WebRing

|

|

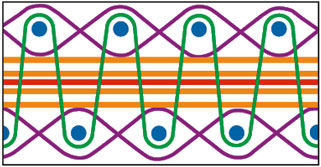

PURPLE: Surface (Weft) yarns carry a portion of the load.

ORANGE: Longitudinal (Warp) yarns carry the majority of the load.

RED: Red core yarns.

BLUE: Lateral yarns woven into the surface yarns.

GREEN: Binder yarns secure the surface and core yarns.

|

|

Lift-It® web slings are fabricated from sling webbing. Sling webbing features a “stuffer” weave construction, where the inner load carrying yarns are jacketed by a protective outer cover. The longitudinal load yarns carry approximately 70% of the load, while the remaining strength is derived from the cover (side-toside) yarns. Red core warning yarns are woven into the central load carrying area. The red core yarns may become visible, as the outer cover is worn away or becomes damaged, providing a signal to users and inspectors to remove the sling from service.

In many applications, slings become extremely dirty, making it difficult to see the red core yarns. Red core yarns cannot be used exclusively to determine the condition of the sling. Red core yarns must be used in conjunction with other removal from service criteria and visual/tactile inspection techniques to determine sling condition. If there is any doubt, do not use the sling. In many applications, slings become extremely dirty, making it difficult to see the red core yarns. Red core yarns cannot be used exclusively to determine the condition of the sling. Red core yarns must be used in conjunction with other removal from service criteria and visual/tactile inspection techniques to determine sling condition. If there is any doubt, do not use the sling.

|

|

MIL-Spec WebRing

|

|

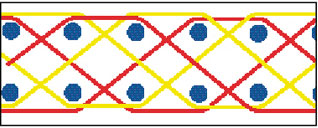

RED: Load carrying surface yarns.

YELLOW: Load carrying surface yarns.

BLUE: Load carrying binder yarns.

|

|

Military specification or “Mil-Spec” webbing is not designed for lifting. Nothing prevents its use in lifting applications, but educated, informed sling purchasers, users and inspectors. “Mil-Spec” webbing does not feature red core yarns and does not employ a stuffer weave design. Since the load carrying yarns are surface exposed, the tensile strength of Mil-Spec webbing, subjected to minor surface damage is radically reduced.

Why would a manufacturer supply “MIL-SPEC” or tie down web for a lifting assembly? The answer is simple, to maximize profit margin. Our problem with that is your safety is compromised.

|

|

Effects of Surface Abrasion

|

|

Red Core Yarn Sensibility

|

|

DESCRIPTION

|

SLING

WEBBING

|

"MIL-SPEC"

WEBBING

|

|

MATERIAL

|

NYLON

|

NYLON

|

|

WIDTH

|

2 IN.

|

1-3/4 IN.

|

|

THICKNESS

|

.12 - .14

|

.15 - .18

|

|

RED CORE YARN

|

YES

|

NO

|

|

FINISH

|

PIGMENT DYE

|

CONDITION "U"

|

|

UNSEWN TENSILE

STRENGTH

|

15,000 Lbs.

|

15,000 Lbs.

|

|

DAMAGE

DESCRIPTION

|

HEAVY

ABRASION

|

LIGHT

ABRASION

|

|

TENSILE STRENGTH

AFTER DAMAGE

|

7,000 Lbs.

|

1,900 Lbs.

|

|

% LOSS

|

53%

|

87%

|

|

WEAR OR DAMAGE TO COVER YARNS OF SLING WEBBING RESULTS IN IMMEDIATE STRENGTH LOSS. WEAR OR DAMAGE TO COVER YARNS OF SLING WEBBING RESULTS IN IMMEDIATE STRENGTH LOSS.

|

|

|

Do not operate under the misconceptions, “If I see red, I’ll be dead” or the red yarns “pop out at you” when the sling is not safe to use or during lifting to alert users of overloading. Pay attention to the many, other removal from service criteria and be a responsible user and inspector.

DO NOT USE SLINGS THAT ARE STRUCTURALLY DAMAGED, IF RED CORE YARNS ARE NOT VISIBLE. DO NOT USE SLINGS THAT ARE STRUCTURALLY DAMAGED, IF RED CORE YARNS ARE NOT VISIBLE.

|

|

Manufacturing Tolerance

|

|

All Lift-It® web slings are manufactured to the following tolerances. For Web slings wider than 6 inches, add 1/2” to the following values. For exact tolerances or matched slings, contact us

|

Sling Thickness

|

Tolerance

|

|

1 Ply

|

1.5 Inches + 1.5% of Sling Length

|

|

2 Ply

|

2.0 Inches + 2% of Sling Length

|

|

3 & 4 Ply

|

3.0 Inches + 3% of Sling Length

|

TREATED WEBBING

Lift-It® slings are manufactured from industrial sling webbing that has been treated in the final stages of looming. The treatment helps seal out moisture and dirt, reducing the effects of abrasion, while enhancing sling service life. Untreated web slings are also available upon request.

|

|

DESIGN FACTOR

All NEW Lift-It® slings are designed and rated with a Design Factor of 5 to 1, unless otherwise stated. When specified, other Design Factors are available. Our slings can be used in compliance with OSHA and ASME specifications. The Design Factor does not allow the user to exceed the Work Load Limit. It is important for sling users to realize Work Load Limits are based upon: destruction testing done in laboratory controlled, testing conditions that will never be duplicated during actual usage and the sling being in a new or “as new” condition.

Any instantaneous change (sudden drops or rapid acceleration) constitutes hazardous shock loading and THE WORK LOAD LIMITS AS STATED, DO NOT APPLY.

|

|

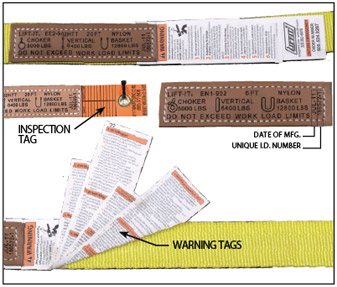

Sling & Warning Tags

|

|

A heavy duty tag is attached to all slings. All necessary information required by the various regulatory agencies is laser imprinted into synthetic leather, resulting in the most durable tag available.

Hitch diagrams, date of manufacture and a unique sling identification number are also included. Custom tags can also be attached for a nominal charge.

In addition to the sling tag, a warning tag is also attached. Developed by the Web Sling and Tie Down Association, it contains important safety, use and inspection information, including removal from service criteria.

Durable, Synthetic Inspection Tags include a matrix for memorialization and visual verification of periodic sling inspections. Synthetic Inspection Tags are available on request for an additional charge.

Proper use, care, inspection and accident prevention measures are enhanced by the Lift-It® Sling and Warning Tag System. If the Sling or Warning Tag becomes detached or illegible, return to us for re-labeling.

|

|

|

|

|

Lift-It Inspection Loop

|

|

|

Slings must be inspected at different levels and at specified times. How does one visually validate that the periodic inspection, done at least annually, has been done?

Sling Inspectors may meticulously track individual slings and rigging equipment, recording the condition. A unique identification number would be necessary to differentiate identical slings or equipment.

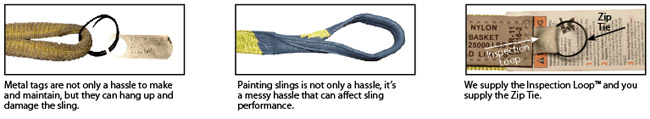

Some inspectors dip the sling into paint (not only a hassle, but a messy hassle) to “visually” signify that the periodic inspection was done. Others attach metal tags that are not only time consuming to make and attach, but could damage the sling by hanging up during use. Zip Ties and colored, electrical tape are also used, but if they are attached too snuggly, they too can cause damage and affect sling strength.

The Lift-It® Inspection Loop™ does not damage slings or components. We supply the Inspection Loop™ and you supply the colorized zip tie denoting the specific inspection interval (month, quarter or year). Imagine the simple beauty of visually surveying multiple slings and easily determining that slings had been inspected during a specific time period. All you need to do is specify, “Inspection Loop” on your order to take the first step to inspection efficiency.

|

|

|