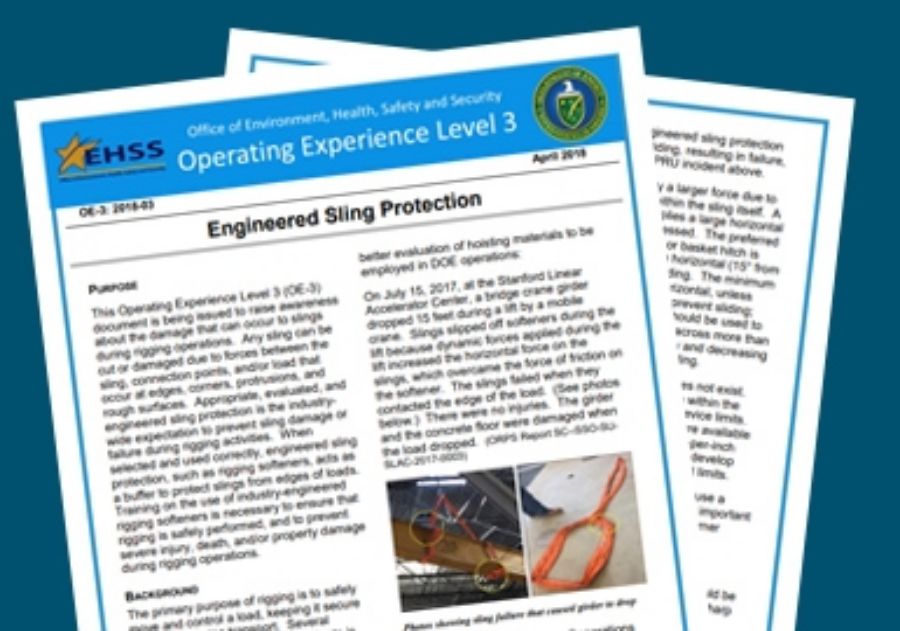

We have worked with many of you over the years to make a difference in the lives of those you are tasked with protecting. Most recently we worked with US DOE representatives to assist in developing some of the information contained in the recently released, “Engineered Sling Protection”, OE-3: 2018-03. The Operating Experience Level 3 issued by Mr. Josh Silverman, Director – Office of Environment, Health, Safety and Security addresses many important considerations and certainly highlights the significance for raising the awareness of damage that may occur to slings during rigging operations.

Much of the specific sling protection language contained in the aforementioned OE is verbatim from the information I have presented over the past thirty-seven years in our training programs. We are honored in our association with the US DOE, a community of professionals who embody a quest for excellence that is difficult to attain and more trying to sustain.

Sling protection like many other devices, if improperly used may injure, kill and/or destroy property. We shipped a very large sling protection order to one of the incident locations mentioned in the OE. We called to thank the purchaser and when we inquired about training for the protection devices were told that the trainer used at their facility would cover training for the sling protection devices received. We sincerely hope that did in deed occur.

In my review of another DOE incident, I had to question the use of the term, “insufficient” used in describing an

internal post incident review of the “sling protection” used at the time. Apparently, it was recognized before the incident that the protection may not be robust enough, but that it had worked many times previously and that despite some doubt, it would work again.

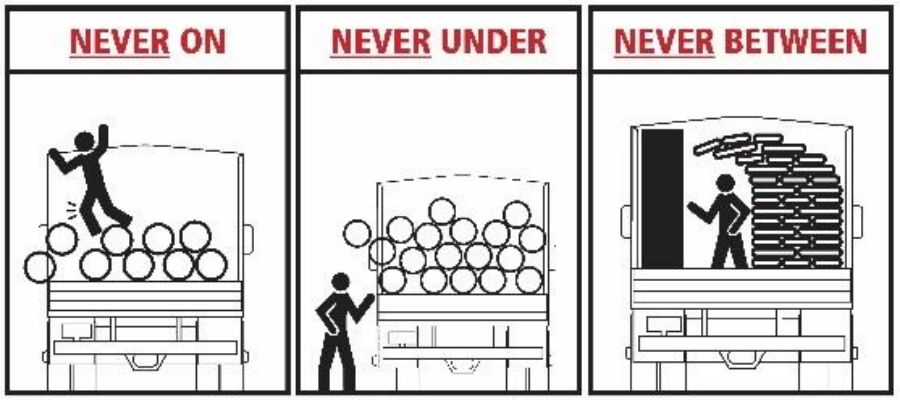

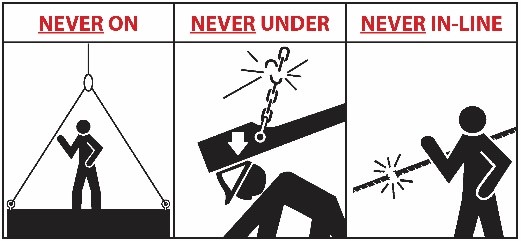

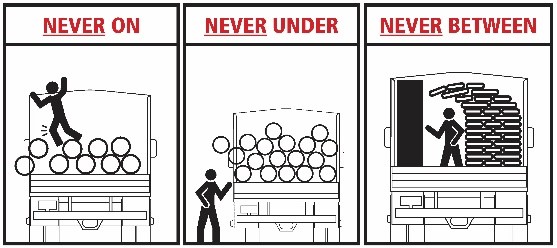

The 2009 Mackey, Henderson report took the blinders off for many as it connected common root cause factors in thirteen separate incidents involving sling damage from cutting. The conclusion reached by Mr. Mackey is a sound one; inadequate and/or non-existent sling protection resulted in sling damage and loss of load control with death, injury and/or property damage as outcomes. Since the release of the report, I have reviewed additional incidents in recent months with identical contributing factors and outcomes.

Lift-It sling protection bulletins will be previewed and discussed in our presentation for the 2018 EPRI-User Group-Hoisting, Rigging and Crane Workshop. The protection bulletins (user manuals) contain valuable information relative to the selection, use and inspection criteria for Lift-It protection devices. They were developed using feedback from sling users representing many diverse industries, as well a development and review process done by industry experts and safety professionals under the guidance of a human factors expert.

On April 24, 2018 at presentation for the Spring 2018 Associated Wire Rope Fabricators I made the point that several manufacturers in attendance promote and sell 1/8” thick bulked nylon products (Cordura®) as “softeners” used for “cut protection”. It is also interesting to note that others who provide training disseminate sling protection information that is not only incorrect, but inherently dangerous.

OE-3 :2018-03 specifically addresses some of the most recent occurrences where rigging professionals, employing “sufficient” sling protection did not complete the load handling activity successfully.

In the April 2018 OE-3, a very compelling point is presented relative to load control as it pertains to the angle of loading and the sling and/or protection device sliding across loads. Charles Lucas, who made significant contributions to the rigging community over a long and distinguished career and I have had many discussions of various load control factors, i.e., coefficients of friction, sling to load angles, sling protection adequacy, etc.

It occurred to me when reading the OE and the prior conversations with Mr. Lucas that the same conclusion (60-degree angle of loading “awareness”) was reached from two, totally independent perspectives. The effects of “low” angles, coefficients of friction, etc. have on successful load handling activities are some of the very important and requisite steps in the proper use of slings and sling protection.

In discussions with US-DOE representatives, methods to effectively disseminate and integrate the vital message(s) of this or any OE into the Department of Energy safety culture were discussed. To be effective, the process needs to permeate all organizational levels and certainly include subcontractor and ancillary personnel.

Training must facilitate and enable modified behavior or reoccurring incidents are certain. It’s not just the message (training program), but the methodology (training techniques) used to transfer the message, which when effectively employed will result in changed behavior. A Train-the-Trainer program may be a key component in improving the effective communication of any message, including that for engineered sling protection.

If you are interested in receiving copies of the Lift-It Sling Protection Bulletins and/or information on our line of Engineered Sling Protection and/or the new and diverse training programs we provide, please contact us.

If there is anything we can do to assist you in gaining traction for action on a site, regional, business sector, etc. level, contact us. Have slings and do travel.

We look forward to hearing from you and to seeing some of you soon at upcoming events.

All the best,

Michael J. Gelskey, Sr.

CEO & Founder

Lift-It Mfg. Company, Inc.