You have no items in your shopping cart.

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

-

Products

- Back

- Training Programs

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

- Round Slings

- Twin-Path Slings

-

Rope Slings

- Back

- Single Leg - Adjustable Rope Slings

- Double Leg - Adjustable Rope Slings

- Polyester Four Leg - Adjustable Rope Slings W/Top Link

- UHMPE PROLINE12™ Rope Slings - Eye & Eye

- UHMPE PROLINE12™ Rope Slings - Endless

- PROLINE12™ UHMPE Adjustable Rope Slings - Single Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Double Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Triple Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Quad Leg

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Nets

-

Rope-Cordage

- Mooring Lines

- Helicopter Rigging

- Recovery Products

- Material Handling

-

Hoists

-

Blocks

- Back

- Rope Blocks

- Tie Downs

- Tool Bags & Buckets

-

Stahlwille

- Back

- Torque Wrenches

- Plate Clamps

- Dynamometers-Load

- Man Baskets

- Safety Resources

- Outrigger Pads

- Featured Products

-

Products

- Back

- Training Programs

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

- Round Slings

- Twin-Path Slings

-

Rope Slings

- Back

- Single Leg - Adjustable Rope Slings

- Double Leg - Adjustable Rope Slings

- Polyester Four Leg - Adjustable Rope Slings W/Top Link

- UHMPE PROLINE12™ Rope Slings - Eye & Eye

- UHMPE PROLINE12™ Rope Slings - Endless

- PROLINE12™ UHMPE Adjustable Rope Slings - Single Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Double Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Triple Leg

- PROLINE12™ UHMPE Adjustable Rope Slings - Quad Leg

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Nets

-

Rope-Cordage

- Mooring Lines

- Helicopter Rigging

- Recovery Products

- Material Handling

-

Hoists

-

Blocks

- Back

- Rope Blocks

- Tie Downs

- Tool Bags & Buckets

-

Stahlwille

- Back

- Torque Wrenches

- Plate Clamps

- Dynamometers-Load

- Man Baskets

- Safety Resources

- Outrigger Pads

- Featured Products

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

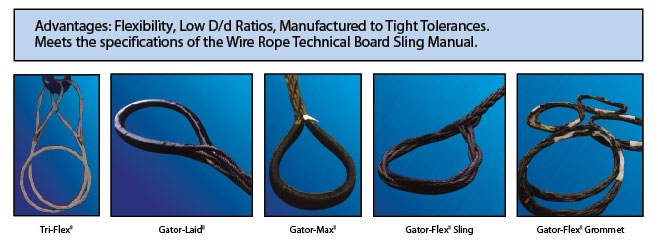

SlingMax Heavy-Lift Wire Rope Slings

|