|

A specific procedure for sling inspection is the best safeguard against injury, death and property damage. It is important that you employ a three stage level of inspection to ensure that slings are inspected with the appropriate frequency. It is also important that all inspections must be done by trained and qualified personnel.

To detect possible damage, you should perform a visual inspection of the entire sling and also feel along its entire length, as some damage may be felt more than seen. You should look and feel for any of the types of conditions listed in the Removal from Service Criteria. Pages 102 and 118 depict examples of some of the types of damage, but note that they are relatively extreme examples provided for illustration purposes only.

If you identify ANY of these types of damage in a sling, remove it from service immediately, even if the damage you see or feel is not as extensive as shown on pages 102 and 118. Slings that are removed from service must be destroyed and rendered completely unusable unless they can be repaired and proof tested by the manufacturer. Never ignore sling damage or attempt to perform temporary field repairs of damaged slings, (i.e., tie knots in the sling, etc.). It is very important that slings are regularly and properly inspected. If you are not sure whether or not a sling is damaged, DO NOT USE IT.

|

|

|

|

|

The Web Sling and Tie Down Association defines the initial level of inspection as, “Before any new or repaired sling is placed in service, it shall be inspected by a qualified person to ensure that the correct sling is being used, as well as to determine that the sling meets the applicable requirements”.

The American Society of Mechanical Engineers also states in the initial inspection that, “prior to use, all new, altered, modified or repaired slings shall be inspected by a designated person to verify compliance to all applicable standards”.

The initial level of inspection is done upon receipt to ensure that no damage has occurred during transit. The products must also be verified to be correct, as ordered and they comply with the manufacturer’s specifications. Without printed product specifications this comparison cannot be accomplished. If written records for individual slings are to be maintained, the documentation should be initiated at this level of inspection. Recordkeeping at the initial level of inspection is not required.

|

|

All slings must be inspected “periodically” by designated personnel at regular intervals. In order to validate the Frequent Level of Inspection, the Periodic Inspection should be done by someone other than the individual(s) who performs the Frequent Inspection. The interval is based upon: the frequency of use, severity of the service conditions, the nature of the work being performed and experience gained during the inspection of slings used in similar circumstances. Recommendations to prevent damage must be evaluated to improve the service life of the replacement slings. Periodic Inspection intervals shall not exceed one year intervals.

ASME stipulates the following time interval guidelines for Periodic Inspections:

- Normal Service - Yearly

- Severe Service - Monthly to Quarterly

- Special Service - As recommended by a Qualified Person

Written records of the most recent periodic inspection shall be maintained. Reference to a unique, sling identification number is not required. If your employer or industry requires recording the condition of individual slings, continue the practice. The important point to realize is the ASME recordkeeping requirement mandates that the event be documented not the condition of individual slings.

Irrespective of the recordkeeping requirements that govern your actions, it is important that slings inspected “periodically” be identified or tracked to validate that the Periodic Inspection occurred. Lift-It® Slings can be equipped with an Inspection Loop™, Inspection Tag or RFID Chipped for easy, visual verification of Periodic Inspections (See pages 54 and 55).

Designated Person: Selected or assigned by the employer or employer’s representative as being competent to perform specific duties.

Qualified Person: A person, who by possession of a recognized degree or certificate of professional standing in an applicable field, or who, by extensive knowledge, training and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.

|

|

|

|

|

The Web Sling and Tie Down Association defines the frequent level of inspection as one that is done by the user or other designated person daily or before each shift in NORMAL service conditions. When SEVERE service conditions exist, the sling must be inspected before each use. See page 476 for definitions of Normal, Severe and Special Service. The entire sling shall be thoroughly examined and removed from service if damage is detected. OSHA and ASME stipulate that, “before each day or shift, the sling and all fastenings and attachments shall be inspected for damage and defects by a competent person designated by the employer”.

If you are unsure if the daily or pre-shift inspection has been done, take the time to inspect the sling before you use it. WSTDA, OSHA and ASME provide minimum guidelines. Never assume that slings have been inspected by others.

A qualified person must also determine that the sling is proper for the intended use, hitch, load and environment. Any condition that may result in a hazard shall cause the sling to be removed from service. Written inspection records are not required for frequent inspections.

|

|

|

|

|

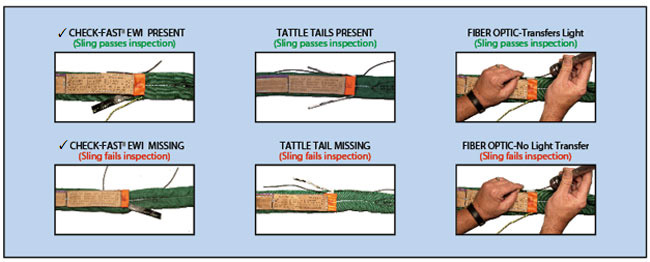

Twin-Path® slings must be inspected thoroughly for damage. Visual, Tactile and patented inspection systems such as ?Check-Fast®, Fiber Optics and Tattle Tails will assist inspectors in determining sling condition. Twin-Path® slings shall be removed from service for an evaluation by the manufacturer if any of the following conditions are detected:

- ?Check-Fast® External Warning Indicator (EWI) and Tattle Tail indicators shall extend past the sling tag area. If slings are equipped with ?Check-Fast® and the EWI is not visible or both Tattle Tails are not visible, remove the sling from service and return to the manufacturer for repair evaluation.

- If slings are equipped with the Fiber-Optic Inspection option, inspect by allowing light to enter the fiber optics. If the fiber optic cable does not transmit light from end to end, remove the sling from service and return for repair evaluation.

- If sling tags are missing or illegible, slings shall not be used and be returned to manufacturer for repair evaluation.

- Inspect slings for evidence of heat damage, i.e., melting, charring or weld spatter. Sparkeater® Slings shall not be exposed to temperatures over 300°F/149°C or below -40°F/-40°C. Twin-Path slings with K-Spec® and polyester core yarn shall not be exposed to temperatures above 180°F/82°C or below -40°F/-40°C.

- If any part of the sling is stiff or brittle, indicating heat or chemical damage, remove the sling from service. Return the sling to the manufacturer for repair evaluation.

- Slings shall be examined throughout their length for damage such as: holes, tears, cuts, embedded materials, abrasive wear or snags that expose the core yarn. If damage is detected, slings shall be removed from service for repair evaluation.

- Damage to the cover may indicate a loss of core yarn strength. Slings with serious cover damage shall not be used until evaluated by the manufacturer.

- If core yarns are broken, cut or damaged, slings must be removed from service. If broken stitching in the cover exposes core yarn, slings must be removed from service and returned to the manufacturer for repair evaluation.

- Twin-Path® slings and attached fittings shall be regularly inspected. In addition to the initial inspection and periodic inspections done by designated, competent inspectors, slings shall be visually inspected before each use.

- Fittings determined to be elongated, damaged, corroded or not AMSE B30.10 and/or ASME B30.26 compliant shall be removed from service and returned to the manufacturer for repair evaluation.

- Slings that are tied in knots or joined by knotting.

- Inspections shall be performed as required by competent persons and inspection documentation shall be maintained. Inspections may be done more often based on: frequency of use, severity of conditions or experience gained on the service life of slings used in similar circumstances. Periodic inspection intervals must not exceed 1 Year.

- Slings removed from service that are not repairable shall be destroyed and rendered completely unfit for any future use.

|

|