|

USE CAUTION IN SEVERE VIBRATION OR SHARP BLOW CONDITIONS

Activities like pile driving can have adverse effects upon product life cycle. Standard cheek plates and overhaul balls are not designed as load bearing members and they can break under extreme vibration or sharp blows.

NEVER USE YIELDING POINT AS A “GAUGE” OF ADEQUACY

Relying upon a fitting to bend before it breaks is a dangerous practice and should never be used as a method to judge product adequacy or to exceed Work Load Limits.

LIFT ONLY LOADS FOR WHICH THE PRODUCTS WERE DESIGNED TO LIFT

Do Not Lift Personnel with systems that are not designed to be used as a compliant, personnel hoist system. Federal crane regulations prohibit the transport of personnel on any load or wire rope attachment.

PERSONNEL CONSIDERATIONS

Instruct workers to keep hands and body away from block sheaves, swivels and “Pinch Points”, where the rope touches block parts or load. Also instruct workers to be alert and to wear proper protective gear while handling loads.

SHEAVE USE PRECAUTIONS

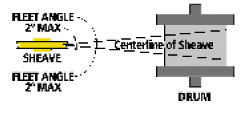

Sheave grooves must be covered with grease before being put into service. Sheave lubrication must be maintained during crane operation. This also implies that crane ropes must be lubricated. In order to protect the sheave groove from undue wear, never allow the fleet angle to exceed

2 degrees.

Apply “good”, initial tension to crane ropes to avoid axial and radial damage in sheave grooves. The wire rope must be properly fitted to avoid rope sliding, resulting in undue wear to the rope and sheaves at the start and stop of each lifting operation.

Sheaves determined to have excessive wear must be replaced by a competent person.

Horizontally assembled sheaves must have holes placed in the cover assemblies cleaned every 3 months to avoid water collection in the curved, inner surface of these sheaves.

NEVER WELD LOAD BEARING COMPONENTS

Any welding to hooks, shackles or other load bearing fittings adversely affects the fitting material strength.

WEDGE SOCKET PRECAUTIONS

Make sure that a sudden jolt or impact does not dislodge the wedge. When installing wire rope, always pre-load the wedge with the wire rope in place. Check frequently to re-tighten or reposition as necessary. Ensure that the wedge is correct for the wire rope size and for the wedge socket.

Make allowances for the “Crimping Effect” common with all types of wedge sockets. Experience shows that it will reduce Work Load Limits by 20%.

|

|

WATER IMMERSION

Do not immerse standard products in water. Special designs are available for fresh and salt water applications.

MAKE SURE WIRE ROPE IS SUFFICIENTLY RATED

Some products have strengths greater than the wire ropes to which they are applied. Consult necessary charts or reference materials to ensure that the type, application and Work Load Limits are correct for all uses. This verification process is the sole responsibility of the end user. Any system, comprised of components is only as strong as the weakest component.

DO NOT OVERLOAD INDIVIDUAL SHEAVES AND BEARINGS

Bearing life expectancy is based upon the use of all available sheaves under maximum parts of line.

A partially reeved block used at the full Work Load Limit is dangerously overloaded. If a block with three sheaves is rated at 30 tons, each sheave will have a bearing capacity of 10 tons. If only two sheaves are used, the reduced WLL is 20 tons, and if only one sheave is used the reduced WLL is 10 tons.

NEVER “TWO BLOCK” OR ALLOW ANY BLOCK OR BALL TO BE DRAWN INTO ANOTHER UNDER POWER

INSPECT EQUIPMENT REGULARLY

If the tag or markings are not legible, do not use any product until it has been properly labeled by a qualified person.

Wear is a fact of life and it will affect fitting cross sections and other critical component dimensions. Worn parts do not have the same WLL as new components and it is the user’s responsibility to determine if any component is fit for continued use. Inspection and testing in accordance with federal, state, provincial, employer or jobsite requirements are necessary to determine continued use.

Be sure to lubricate bearings and other moving parts at regular intervals to prevent damage. For general maintenance instructions, please consult the Owner’s Manual. Be sure when replacement parts are used that they are genuine, original manufacturer parts. Do Not Modify any product.

Inspect for damage which will require replacement or removal of the product from service:

Wear on pins, axles, rope grooves, side plates, bearings, bushings and fittings.

Deformation in side plates, pins, axle fitting attachment points or component parts.

- Deformation or corrosion of hook and nut threads.

- Weld corrosion or cracking.

- Deformation of hook and signs of wear.

- Any hook, fitting or component that is cracked, gouged or distorted.

If you have any doubt as to the strength or continued use of any product, DO NOT USE, until you have consulted a qualified person.

The hook latch must properly operate and fit. The hook latch must properly operate and fit.

Verify the security of nuts, bolts and other locking devices, especially after reassembly following a repair or inspection.

|