|

The The  Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations. Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations.

It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous. It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous.

The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard clearly establishes the requirement for training. Section 9-1.1-Training states, “Chain sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.” The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard clearly establishes the requirement for training. Section 9-1.1-Training states, “Chain sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.”

All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations. All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations.

Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others.

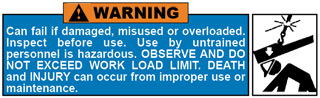

Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained. Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained.

|

|

Any hazardous condition disclosed by an inspection shall require sling replacement. Temporary repairs are not permitted. Damage and wear seriously reduce sling Work Load Limits.

Always know the load weight and select the appropriate sling for the load, configuration of lift necessary to ensure load control and any chemical exposure.

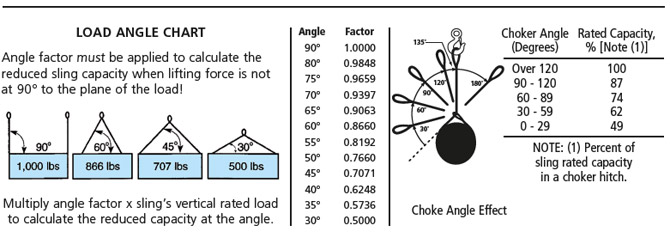

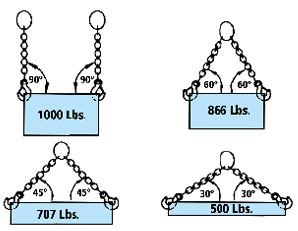

Always take into account sling angles to calculate changes in the sling Work Load Limits, when used in choker and non-perpendicular vertical, basket or bridle configurations.

Ensure that the load will not cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces with suitable materials of sufficient strength, thickness and construction.

The strength of Chain Slings can be affected by chemically active environments. Sling materials may be susceptible to damage from caustic or acid substances or fumes. Strong oxidizing environments attack all common sling materials and components. Consult the manufacturer prior to selection and use.

|

|

|

| INSTRUCTIONS FOR CARE, USE, INSPECTION, & REPAIR |

CARE

Store chain slings on a rack away from possible mechanical damage, corrosion, moisture, dust, grit and extreme temperatures. Oil prior to prolonged storage. Do not anneal (temper) alloy chain, connecting links or hooks. For hot galvanized chain products consult the manufacturer.

USE

Know the weight of load. Check tag to confirm that sling is rated adequately for the load (see load angle chart). Avoid twists, knots or kinks Be sure that the load can’t cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces; use materials of sufficient strength, thickness and construction. Center the sling in the base (bowl) of sling hook unless sling hook is designed for point loading. Balance the load. Maintain load control. Avoid jerking the load. Be alert for snagging of load. Do not pull on stuck objects. Avoid dragging sling over rough surfaces and from under the load. Choker hitch must choke on sling body, never on a fitting. Stand clear of load at all times. Persons are not to ride on sling or load. If sling is to be used in a chemical environment, contact manufacturer for specific recommendations. Do not use chain slings at temperatures above 400º F or below -40º F. When shortening chain, use only the manufacturer’s recommended alloy components.

INSPECTION

Before each use: Check for nicks, gouges or excessive wear. Inspect for bent, twisted, deformed chain or components. Inspect for heat damage, weld spatter, pitting or corrosion, increase in hook throat opening, missing latch (if so equipped). If this wear or damage is present, if rated load tag is missing or illegible; remove from service and repair or replace sling. Periodic Inspections are required at least annually for normal service, quarterly or more frequently if in severe service or nearly constant use. Periodic inspections are performed by designated person(s) who are trained and a written record of the most periodic inspection shall be maintained and shall include the condition of the sling. The inspector shall determine when further use would be hazardous.

REPAIR

If any hazardous condition is disclosed during an inspection, the sling shall be removed from service and shall require repair by chain sling manufacturer or a qualified person. All repaired slings shall be proof tested and certified.

|

|

|

Because of the reduced lifting capacity, use extra care when the horizontal lift angle is less than 45° and do not make lifts of less than 30° load angle. Example: A sling with adequate capacity could be broken because of increased tension resulting from angles of less than 30 degrees. When possible, use longer slings to minimize angular tension by increasing the angle.

|

| Gunnebo Lifting Grade 80 and Grade 100 Alloy Steel Chain Slings |

|

The following information contains warnings and use information applicable to Gunnebo Lifting Grade 80 and Grade 100 Alloy Steel Chain Slings and components and is furnished with all shipments.

Never use a sling without training, OSHA regulation requires responsible work practice.

“The employer shall permit only those employees qualified by training or experience to operate equipment and machinery.” OSHA 1926.20 (b) (4).

Employee training should include information given in OSHA training literature, ASME B30.9 “Slings” and ASME B30.10 “Hooks” safety standards and this document.

Always inform yourself and ask your employer for chain sling, safe use instruction.

“The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” OSHA 1926.21 (b) (2).

Always comply with applicable Federal and local regulations, which govern worksite activity.

Understand all governing laws and safety standards before using chain slings. OSHA 1910.184 regulates

chain sling safe operating practices, product identification, inspection requirements, and use limitations. ASME B30.9 “Sling” safety standard provides additional recommendations for chain sling use.

“If a particular standard is specifically applicable to a condition, practice, means, method, operation or process, it shall prevail over any different general standard.” OSHA 1910.5 (c) (1).

Contact OSHA at (800) 321-6742 or www.OSHA.gov and ASME at (800) 843-2763 or www.ASME.org for reference assistance.

Always know load weight to avoid sling failure.

ASME B30.9-1.10.1 (c) stipulates, “The rated load of the sling shall not be exceeded.”

The weight of the load to be lifted must be known for determination of proper sling configuration and Work Load Limit.

|

| |

|

PROTECT YOURSELF AND OTHERS:

|

|

- Never use a sling without training.

- Always inform yourself. Ask your employer for the manufacturer’s sling use limitations.

- Always comply with applicable Federal and local regulations.

- Always know load weight.

- Never use a sling without a legible capacity tag.

- Never overload a sling. Never ride on sling or load.

- Never use an improper sling configuration.

- Never use a worn-out or damaged sling.

- Never use a sling in extreme temperatures.

- Never use a sling in acidic conditions.

|

|

|

CHAIN SLING FAILURE CAN CAUSE

DEATH OR INJURY

SLING FAILURE RESULTS FROM MISUSE, DAMAGE AND

EXCESSIVE WEAR

|

|

|

Never use a sling without a legible identification tag. Sling identification is required to ensure proper sling usage.

OSHA 1910.184 (e) (1) states, “Alloy steel chain slings shall have permanently affixed, durable identification stating size, grade, rated capacity and reach.”

OSHA 1910.184 (e) (2) (i) states, “Hooks, rings or other attachments shall have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling shall not be used in excess of the rated capacity of the weakest component.“

OSHA 1910.184 (e) (2) (ii) states, “Makeshift links or fasteners shall not be used.”

Lift-It® provides an identification tag, attached by a coupler stamped with: sling WLL, sling angle, serial number, chain size, grade, reach, type and manufacturer.

Grade of the component with the lowest breaking strength shall be specified on the identification tag. Non-standard grades shall be designated by “NS”.

Work Load Limit (WLL) is the maximum Work Load for a specified working range. Sling working range includes sling angles from 90° to a specified minimum.

Work Load is to be applied vertically to a sling assembly having symmetrical leg angles. WLL applies to loads lifted vertically and does not include torsional, binding, shock or non-symmetrical load effects.

Gunnebo Lifting Grade 80 & Grade 100 Alloy Steel Chain Vertical and Basket Sling Work Load Limits for selected working ranges of symmetrical sling leg angles are listed in pounds and given in TABLES 1A and 1B. No chain sling shall be rigged with a leg angle less than 30° from the horizontal.

ASTM A906/A 906M – 02-9.2 states: “Slings containing any Grade 80 components shall be rated at Grade 80 Work Load Limits.”

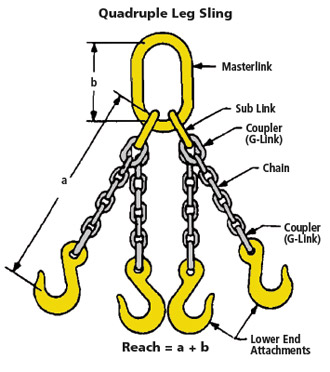

Double Leg and Single Basket Sling WLL for an alternate working range of symmetric sling leg angles equals (=) 2x TABLE 1A or 1B single leg WLL x sine of the minimum working range angle.

Triple and Quadruple leg and Double Basket Sling WLL for an alternate working range of symmetrical sling leg angles equals (=) 3 x TABLE 1A or 1B single leg WLL x sine of the minimum working range angle.

TABLE 2 lists for convenience sine values for selected sling leg angles.

|

|

TABLE 2

|

|

Angle

|

Sine

|

Angle

|

Sine

|

Angle

|

Sine

|

|

85

|

.996

|

70

|

.940

|

50

|

.766

|

|

80

|

.985

|

65

|

.906

|

40

|

.643

|

|

75

|

.966

|

55

|

.819

|

35

|

.574

|

|

|

Multi Leg and Basket Sling WLL for non-symmetrical loading can only be determined by an engineering analysis of the specific rigging condition. In the absence of an engineering analysis, WLL shall be equal to single leg sling WLL given in TABLE 1A or 1B.

|

|

TABLE 1A- GR 80 ALLOY STEEL CHAIN SLING WORK LOAD LIMITS* (Lbs.)

DESIGN FACTOR 4/1

|

|

GUNNEBO LIFTING

GR 80

CHAIN SIZE

|

SINGLE LEG

|

DOUBLE LEG

|

TRIPLE & QUAD LEG

|

|

MM

|

IN

|

90°

|

90° - 60°

|

90° - 45°

|

90° - 30°

|

90° - 60°

|

90° - 45°

|

90° - 30°

|

|

6

|

7/32

|

2,100

|

3,600

|

3,000

|

2,100

|

5,450

|

4,450

|

3,150

|

|

7

|

9/32

|

3,500

|

6,100

|

4,900

|

3,500

|

9,100

|

7,400

|

5,200

|

|

8

|

5/16

|

4,500

|

7,800

|

6,400

|

4,500

|

11,700

|

9,500

|

6,800

|

|

10

|

3/8

|

7,100

|

12,300

|

10,000

|

7,100

|

18,400

|

15,100

|

10,600

|

|

13

|

1/2

|

12,000

|

20,800

|

17,000

|

12,000

|

31,200

|

25,500

|

18,000

|

|

16

|

5/8

|

18,100

|

31,300

|

25,600

|

18,100

|

47,000

|

38,400

|

27,100

|

|

19

|

3/4

|

25,500

|

44,100

|

36,000

|

25,500

|

66,200

|

54,000

|

38,200

|

|

20

|

3/4

|

28,300

|

49,000

|

40,000

|

28,300

|

73,500

|

60,000

|

42,400

|

|

22

|

7/8

|

34,200

|

59,200

|

48,400

|

34,200

|

88,900

|

72,500

|

51,300

|

|

26

|

1

|

47,700

|

82,600

|

67,400

|

47,700

|

123,900

|

101,200

|

71,500

|

|

32

|

1-1/4

|

72,300

|

125,200

|

102,200

|

72,300

|

187,800

|

153,400

|

108,400

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

|

|

TABLE 1B - GR 100 ALLOY STEEL CHAIN SLING Work Load LimitS*(Lbs.)

DESIGN FACTOR OF 4/1

|

|

GUNNEBO

GR 100

CHAIN SIZE

|

SINGLE LEG

|

DOUBLE LEG

|

TRIPLE & QUAD LEG

|

|

MM

|

IN

|

90°

|

90° - 60°

|

90° - 45°

|

90° - 30°

|

90° - 60°

|

90° - 45°

|

90° - 30°

|

|

5.5

|

7/32

|

2,700

|

4,700

|

3,800

|

2,700

|

7,000

|

5,700

|

4,000

|

|

7

|

9/32

|

4,300

|

7,400

|

6,100

|

4,300

|

11,200

|

9,100

|

6,400

|

|

8

|

5/16

|

5,700

|

9,900

|

8,100

|

5,700

|

14,800

|

12,100

|

8,500

|

|

10

|

3/8

|

8,800

|

15,200

|

12,400

|

8,800

|

22,900

|

18,700

|

13,200

|

|

13

|

1/2

|

15,000

|

26,000

|

21,200

|

15,000

|

39,000

|

31,800

|

22,500

|

|

16

|

5/8

|

22,600

|

39,100

|

32,000

|

22,600

|

58,700

|

47,900

|

33,900

|

|

20

|

3/4

|

35,300

|

61,100

|

49,900

|

35,300

|

91,700

|

74,900

|

53,000

|

|

22

|

7/8

|

42,700

|

74,000

|

60,400

|

42,700

|

110,900

|

90,600

|

64,000

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

|

|

Choked chain sling WLL is affected by choke angle. TABLE 3A and 3B illustrates choke angle and gives Sling Choker WLL’s as a percentage of the WLL shown in TABLES 1A and 1B for full range of choke angles.

|

|

TABLE 3A GR 80

|

|

|

Choke

Angle

|

Percentage Of

TABLE 1A WLL

|

|

120 - 180

|

100%

|

|

90 - 119

|

87%

|

|

60 - 89

|

74%

|

|

30 - 59

|

62%

|

|

0 - 29

|

49%

|

|

|

TABLE 3B GR 100

|

|

|

Choke

Angle

|

Percentage Of

TABLE 1B WLL

|

|

120 - 180

|

80%

|

|

90 - 119

|

70%

|

|

60 - 89

|

60%

|

|

30 - 59

|

50%

|

|

0 - 29

|

40%

|

|

|

|

Choked Endless Chain Sling WLL’s for selected Gunnebo Lifting Grade 80 and Grade 100 chain leg angles are listed in TABLES 4A and 4B.

|

|

Table 4A GR 80 - CHOKED ENDLESS CHAIN SLING

Work Load LimitS (Lbs.) Design Factor 4/1

|

|

|

GUNNEBO GRADE 80

|

CHOKER WLL

(Lbs.)

|

|

CHAIN SIZE

|

ENDLESS

|

|

MM

|

IN

|

90°

|

90° - 60°

|

90° - 45°

|

|

6

|

7/32

|

3,150

|

2,700

|

2,250

|

|

7

|

9/32

|

5,250

|

4,575

|

3,675

|

|

8

|

5/16

|

6,750

|

5,850

|

4,800

|

|

10

|

3/8

|

10,600

|

9,200

|

7,500

|

|

13

|

1/2

|

18,000

|

15,600

|

12,700

|

|

16

|

5/8

|

27,100

|

23,400

|

19,200

|

|

19

|

3/4

|

38,200

|

33,000

|

27,000

|

|

20

|

3/4

|

42,400

|

36,700

|

30,000

|

|

22

|

7/8

|

51,300

|

44,400

|

36,300

|

|

26

|

1

|

71,500

|

61,900

|

50,500

|

|

32

|

1-1/4

|

108,400

|

93,900

|

76,600

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

|

|

Table 4B GR 100 - CHOKED ENDLESS CHAIN SLING

Work Load LimitS (Lbs.) Design Factor 4/1

|

|

|

GUNNEBO GRADE 100

|

CHOKER WLL

(Lbs.)

|

|

CHAIN SIZE

|

ENDLESS

|

|

MM

|

IN

|

90°

|

90° - 60°

|

90° - 45°

|

|

5

|

7/32

|

4,000

|

3,500

|

2,800

|

|

7

|

9/32

|

6,400

|

5,500

|

4,600

|

|

8

|

5/16

|

8,500

|

7,400

|

6,100

|

|

10

|

3/8

|

13,200

|

11,400

|

9,300

|

|

13

|

1/2

|

22,500

|

19,500

|

15,900

|

|

16

|

5/8

|

33,900

|

29,300

|

24,000

|

|

20

|

3/4

|

52,900

|

45,800

|

37,400

|

|

22

|

7/8

|

64,000

|

55,500

|

45,300

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

|

|

|

|

Never overload a sling by understanding Work Load Limits.

OSHA 1910.184 (c) (4) stipulates, “Slings shall not be loaded in excess of their rated capacities.”

ASME 830.9-1.4 states, “The design factor for alloy steel chain slings shall be a minimum of 4.”

Standard Gunnebo Lifting Work Load Limits (WLL) are based on a 4/1 design factor. Lift dynamics, duty cycle and hitch type may require an increased design factor, hence a reduced WLL. Inattention to required design factor can result in sling overload.

Sling WLL depends on the sling leg angle. The WLL for a sling is reduced as the horizontal sling leg angle gets smaller. This fact applies to all multi-leg and basket slings and must not be ignored.

The following diagram illustrates the effect of sling leg angle on the WLL for a single basket and two-leg sling.

|

The WLL of a sling with a 30° leg angle is 50% of the WLL for the same sling with a 90° leg angle. Inattention to the effect of sling leg angle can result in sling overload.

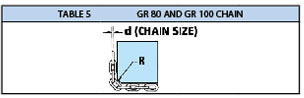

Chain sling WLL is to be reduced in accordance with TABLE 5 when chain is rigged over an edge radius (R) less than two (2) x the chain rod diameter (d).

Reduced WLL equals chain sling WLL from identification tag x reduction factor.

|

Edge Radius

|

R>2 x Chain d

|

R> Chain d

|

R< Chain d

|

|

Reduction Factor

|

1.0

|

0.7

|

0.5

|

|

Never ride on sling or load and avoid death and injury.

OSHA 1910 184 (c) (9) Sling Use regulations require that: “All employees shall be kept clear of loads about to be lifted and of suspended loads.”

OSHA 1910.180 (h) (3) (v) General Worksite regulations require that: “No hoisting, lowering, swinging or traveling shall be done while anyone is on the load or hook assembly.”

OSHA 1926.550 (g) (2) Construction Worksite Regulation stipulates: “The use of a crane or derrick to hoist employees on a personnel platform is prohibited, except when the erection, use and dismantling of conventional means of reaching the worksite, such as a personnel hoist, ladder, stairway, aerial lift, elevating work platform or scaffold would be more hazardous or is not possible because of structural design or worksite conditions.”

Alloy steel chain slings shall not be used to rig personnel platforms.

Never rig a sling to load improperly and avoid dropped loads and sling damage.

Safe operating practices per OSHA 1910.184 (c) and operating practices per ASME B30.9-1.10 state:

- Sling leg shall not be less than 30° from the horizontal.

- Slings shall be shortened with a shortening hook only and not with knots or bolts or other makeshift devices.

- Sling legs shall not be kinked or twisted.

- Sling hooks shall not be point loaded.

- Sling hook latch may be mandatory by regulation, safety codes or insurance.

- Slings used in a basket hitch shall have the loads balanced to prevent slipping.

- Slings shall be securely attached to their loads.

- Slings shall be padded or protected from the edges of their loads when the edge radius is less than .5 of the chain rod diameter (d). See TABLE 5.

- Sling shall be rigged to prevent chain from sliding over a load edge radius while lifting.

|

|

Never use a worn-out or damaged sling.

“Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use where service conditions warrant. Damaged or defective slings shall be immediately removed from service”

OSHA 1910.184 (d).

“In addition to the inspection required by paragraph 1910.184(d), a thorough periodic inspection shall be made on a regular basis, to be determined on the basis of:

- frequency of sling use;

- severity of service conditions;

- nature of lifts being made;

- experience gained on the service life of slings used in similar circumstances.

Such inspections shall in no event be at intervals greater than once every 12 months.”

OSHA 1910.184 (e) (3) (i).

“The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.” OSHA 1910.184 (e) (3) (iii)

“Worn or damaged alloy steel chain slings or attachments shall not be used until repaired.” OSHA 1910.184 (e) (7) (i).

A chain sling with reach longer than given on identification tag shall be immediately removed from service and evaluated for wear and material stretch.

Chain link wear is limited by minimum cross-sectional dimensions given in TABLE 6. Chain worn below the given limits shall be removed from service.

A chain sling connector or attachment with wear greater than 10 percent of the original dimension for any cross section shall be removed from service.

|

TABLE 6 GR80 AND GR100

|

|

Nominal Chain or

Coupling Link Size

|

Minimum Cross-Sectional "C" Dimensional Limit

|

|

mm.

|

in.

|

mm.

|

in.

|

|

6

|

7/32

|

5.2

|

.205

|

|

7

|

9/32

|

5.9

|

.239

|

|

8

|

5/16

|

6.9

|

.273

|

|

10

|

3/8

|

8.7

|

.342

|

|

13

|

1/2

|

11.3

|

.443

|

|

16

|

5/8

|

13.9

|

.546

|

|

19

|

3/4

|

16.3

|

.643

|

|

20

|

3/4

|

16.9

|

.665

|

|

22

|

7/8

|

19.0

|

.750

|

|

26

|

1

|

22.5

|

.887

|

|

32

|

1-1/4

|

27.7

|

1.091

|

A chain sling coupler, chain, G-Link, masterlink,

sub-link, hook or attachment that is broken, cracked, bent, stretched or twisted shall be removed from service and shall not be repaired.

Chain slings with a coupler, chain, G-link, masterlink, sub-link, hook or attachment that is nicked or gouged or lapped shall be removed from service and shall not be returned to service unless properly repaired.

Hook latch, when required, shall be fully functional and properly seated.

Never use a sling in alkaline or acidic conditions.

Gunnebo Lifting Grade 80 and Grade 100 alloy steel chain and components shall not be used in alkaline or acidic conditions. Resulting metal embrittlement and accelerated corrosion can cause sudden sling failure. Hot dip galvanizing and electro-zinc plating of alloy steel chain and components shall be done only by Gunnebo.

Never use a sling in extreme temperatures.

“Alloy steel chain slings shall be permanently removed from service if they are heated above 1000°F”. OSHA 1910.184 (e) (6).

Alloy steel chain slings shall not be used while heated above 1000°F or cooled below -40°F.

Alloy steel chain sling Work Load Limits (WLL) given in TABLE 1A or 1B are valid between temperatures of -40°F and 400°F.

|

|

|

Alloy steel chain sling WLL shall be reduced in accordance with TABLES 7A or 7B when heated between 400°F and 1000°F.

Permanent WLL reduction shall be made in accordance with TABLE 7A or 7B for chain slings heated over temperatures indicated. Identification tag shall be replaced and the new tag shall have the reduced WLL.

|

|

TABLE 7A GR 80 Chain and Components

|

|

Sling Component

Temperature

|

Percentage of TABLE 1A AND 4A WLL

|

|

During Exposure

|

After Exposure

|

|

-40°F to 400°F

|

None

|

None

|

|

>400°F to 500°F

|

95%

|

None

|

|

>500°F to 600°F

|

90%

|

None

|

|

>600°F to 700°F

|

82%

|

None

|

|

>700°F to 800°F

|

75%

|

90%

|

|

>800°F TO 900°F

|

65%

|

75%

|

|

>900°F TO 1000°F

|

60%

|

70%

|

|

|

|

TABLE 7B GR 100 Chain and Components

|

|

Sling Component

Temperature

|

Percentage of TABLE 1B AND 4B WLL

|

|

During Exposure

|

After Exposure

|

|

-40°F to 400°F

|

None

|

None

|

|

>400°F to 500°F

|

95%

|

95%

|

|

>500°F to 600°F

|

90%

|

90%

|

|

>600°F to 700°F

|

82%

|

85%

|

|

>700°F to 800°F

|

75%

|

80%

|

|

>800°F TO 900°F

|

65%

|

75%

|

|

>900°F TO 1000°F

|

60%

|

70%

|

|

|

|

|