You have no items in your shopping cart.

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

-

Products

- Back

- Recovery Products

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

-

Round Slings

- Back

- Endless Round Slings

- Twin-Path Slings

- Rope Slings

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Material Handling

-

Stahlwille

- Back

- Torque Wrenches

- Tool Bags & Buckets

- Tie Downs

-

Hoists

- Misc.

- Training Programs

- Plate Clamps

-

Blocks

- Back

- Rope Blocks

-

Rope-Cordage

- Nets

- Safety Resources

- Helicopter Rigging

- Featured Products

-

Products

- Back

- Recovery Products

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

-

Round Slings

- Back

- Endless Round Slings

- Twin-Path Slings

- Rope Slings

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Material Handling

-

Stahlwille

- Back

- Torque Wrenches

- Tool Bags & Buckets

- Tie Downs

-

Hoists

- Misc.

- Training Programs

- Plate Clamps

-

Blocks

- Back

- Rope Blocks

-

Rope-Cordage

- Nets

- Safety Resources

- Helicopter Rigging

- Featured Products

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

Lift-It® Manufacturing - Repair and Testing

|

If repair work is necessary, it must be economically feasible and should only be done by a recognized sling manufacturer. Tent, awning, shoe and saddle shops are not equipped to test the repaired assembly and generally are not proficient in sling fabrication techniques.

Recycle your hardware, when the sling needs webbing replacement. Generally, the hardware components are reusable and utilization will substantially reduce overall sling costs. When we receive your components they are degreased and carefully inspected.

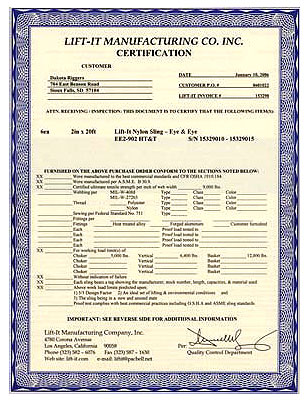

Repaired assemblies are proof tested to twice the assigned work load limit, per OSHA and ASME requirement. This procedure is done on equipment, which is annually certified to ASTM E4 standards and produces a machine generated record of each test. Beware of “testing” facilities that do not have the capabilities to offer a “machine” generated certificate of test.

An additional tag is attached to the assembly identifying Lift-It® as the repair agent. The test certificate is enclosed with the return shipment and your inspection records should be updated to reflect the repair activity, per OSHA requirements. Lift-It® will provide certification of conformance for materials, strengths and work load limits for any of our products. A nominal charge will be applied if proof testing and certification are required.

|