Crosby® Rigging Information

|

IMPORTANT INFORMATION: READ, UNDERSTAND AND FOLLOW. IMPORTANT INFORMATION: READ, UNDERSTAND AND FOLLOW.

|

|

|

|

|

|

|

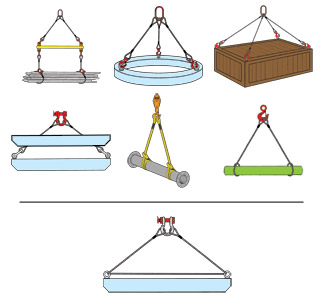

Plan every lift, include the following questions with the questions your experience provides:

1. Who is responsible (competent) for the rigging?

2. Have communications been established?

3. Is the rigging in acceptable condition?

4. Is the rigging appropriate for lifting?

5. Does the rigging have proper identification?

6. Does all gear have known Work Load Limits?

7. What is the weight of the load?

8. Where is the load’s center of gravity?

9. What is the sling angle?

10. Will there be any side or angular loading?

11. Are the slings padded against damaging corners?

12. Are the Work Load Limits adequate?

13. Is the load rigged to the center of gravity?

14. Is the hitch appropriate for the load?

15. Is a tag line required to control load?

16. Will personnel be clear of suspended loads?

17. Is there any possibility of fouling?

18. Will the load lift level and be stable?

19. Any unusual environmental concerns?

20. Any special requirements?

The rigging must be used within manufacturer’s

recommendations and industry standards that

include: OSHA, ASME, ANSI, API and others.

|

USER RESPONSIBILITY

- Utilize appropriate rigging gear suitable for lifting.

- Utilize the rigging gear within industry standards and the manufacturer’s recommendations.

- Conduct regular inspection and maintenance of the rigging gear.

- Provide employees with training to meet OSHA and

ASME (B30.9, B30.26, etc.) requirements.

MANUFACTURER’S RESPONSIBILITY

- Product and application information.

- Product is clearly identified:

Name or logo

Load rating and size

Traceability

- Product performance:

Work Load Limit

Ductility

Fatigue properties

Impact properties

- Product training and training resources.

|

INSPECTION OF RIGGING HARDWARE

|

INSPECTION FREQUENCY PER ASME B30.26

A visual inspection shall be performed by the user or designated person before each shift or day the rigging hardware is used. A periodic inspection shall be performed by a designated person, at least annually. The rigging hardware shall be examined and determination made as to whether damage constitutes a hazard. Written records are not required.

Semi-permanent and inaccessible locations where frequent inspections are not feasible shall have periodic inspections performed.

|

|

REJECTION CRITERIA PER ASME B30.26

|

- Missing or illegible manufacturer’s name or trademark and/or rated load identification (or size as required).

- A 10% or more reduction of the original dimension.

- Bent, twisted, distorted, stretched, elongated, cracked or broken load bearing components.

- Excessive nicks, gouges, pitting and corrosion.

- Indications of heat damage including weld spatter or arc strikes and/or evidence of unauthorized welding.

- Loose or missing nuts, bolts, cotter pins, snap rings or other fasteners and retaining devices.

- Unauthorized replacement components or other visible conditions that cause doubt as to the continued use of the fitting.

|

Additionally inspect wire rope clips for:

- Insufficient number of clips

- Incorrect spacing between clips

- Improperly tightened clips

- Indications of damaged wire rope or wire rope slippage

- Improper assembly

Additionally, inspect wedge sockets for:

- Indications of damaged wire rope or wire rope slippage

- Improper assembly

|

|

REJECTION CRITERIA PER ASME B30.10 – HOOKS

|

|

Any visibly apparent bend or twist from the plane of an identical, unbent hook. Any distortion causing an increase in throat opening of 5%, not to exceed 1/4”.

|

|

ASME B30.9 OPERATING PRACTICES

|

|

Whenever any sling is used, the following practices shall be observed.

- Slings that are damaged or defective shall not

be used.

- Slings shall not be shortened with knots or bolts or other makeshift devices.

- Sling legs shall not be kinked.

- Slings shall not be loaded in excess of their

rated capacities.

- Slings used in a basket hitch shall have the loads balanced to prevent slippage.

- Slings shall be securely attached to their load.

- Slings shall be padded or protected by materials of sufficient strength, thickness and construction from the damaging edges of their loads.

- Suspended loads shall be kept clear of all obstructions.

- All employees shall be kept clear of loads about to be lifted and of suspended loads.

- Hands or fingers shall not be placed between the

sling and its load while the sling is being tightened around the load.

- Shock loading is prohibited.

- A sling shall not be pulled from under a load when the load is resting on the sling.

|

|

|

|

|

|

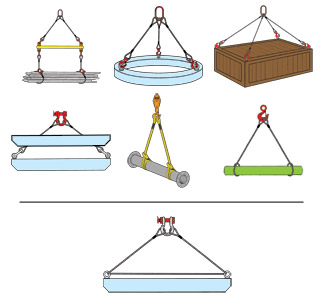

REEVING THROUGH CONNECTIONS TO LOAD

INCREASES LOAD ON CONNECTION FITTINGS

BY AS MUCH AS TWICE

DO NOT REEVE!

|

|

|

|

Inspection: Each day or before each shift, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

|

| |

|

|