Cutting / Damaging Edges

Winch lines should not be exposed to edges and surfaces such as metal burrs on winch drums, sheaves, shackles, thimbles, wire rope slings, etc. Winch lines can be cut or damaged by edge contact. When installing winch lines, great care must be taken to ensure that the rope will not contact surfaces that have been scored and chewed. Sheaves, shackles, thimbles, etc. must be replaced if they are determined to be damaged. Other surfaces should be carefully examined and dressed down if necessary.

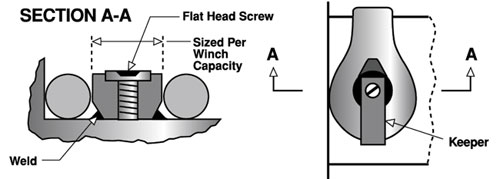

Attaching Line to Winch Drum

There are various methods of attaching a winch line to a winch drum: the use of a wedge or plug and set screw in the main body of the drum or a “U” bolt through the side of the flange. Another method involves welding a round plug to the winch drum. The soft eye at the captivated end of the winch line is placed over the plug and held in place with a flat keeper. Be sure the attachment method does not have damaging edges that will cut the line under load. It is advisable to have an eye splice in both ends of the winch line so that it can be reversed.

|

This is not always possible, depending upon the method of attachment to the winch drum and if a closed thimble is spliced into the eye. If an eye is not used at the drum end, then this end should be tightly whipped with strong twine.

Important Note: The end connection is not designed to carry any load, so at least four wraps should always be kept on the drum. If the winch line is AmSteel® Blue or AmSteel®, then the number of wraps on the drum should be increased to eight.

|

|

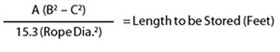

Rope Capacity of a Winch Drum

|

The formula for determining the length of rope that will fit on a winch drum is:

A, B, C and rope diameter are expressed in inches.

|

|

The first layer (wrap) around the winch drum should be put on closely and tightly. Initial winding tension (load) should be approximately 50 Lbs. This will prevent subsequent wraps from slipping down between turns when tension is applied. Samson winch lines tend to self-level.

Important Note: Samson recommends at least four wraps* always be left on the winch drum. Due to the low coefficient of friction, If AmSteel® or AmSteel® Blue winch lines are used, there must be at least eight wraps left on the drum while the line is being used.

Level Winding: Using the appropriate amount of tension, wind the rope evenly, without spaces across the drum of the winch. The next level should wind over the previous layer of rope and follow the valley between turns on the previous level. The pattern is followed for all layers of rope with each layer of turns slightly offset from the layer below.

Cross Winding: When the rope is placed under load it can dive or push into the previously wrapped level below it. To avoid diving, cross winding is recommended.

When cross winding, start with two layers of level wound rope using the appropriate back tension. At the end of the second layer, pull the rope quickly across the drum, allow it to wind one full turn at the side of the drum and then quickly pull it back to the opposite side of the drum. This will force the rope to cross in the middle and form a barrier that will prevent the rope form diving into the lower layers of the drum when placed under load. Follow the cross wound layer with two layers of level wound turns, then form another cross in the middle. Repeat this pattern until the length of rope is fully spooled onto the winch.

End for End Rotation

It is recommended that every winch line be rotated end for end on a periodic basis. Rotation will change the high stress and wear points and provide for a useful service life. The general, recommended period is 6 months and during rotation inspection and washing can be performed.

Abrasion Protection

Stable braid, AmSteel® II and Validator have outer jackets of polyester which provides resistance to abrasion and fusing. However all synthetics are subject to fusing if subjected to enough friction and heat. Therefore, such practices as surging on Gypsy-head winches, hard rendering around poles or over cross-arms, etc. should be avoided. (Not a racial slur, Gypsy-head is a common term).

Use of Slings with Winch Lines

The winch line should not be used as a “sling” to pick up objects. The hook at the end of the winch line can damage the rope. We recommend that a sling be used to attach objects to the winch line hook.

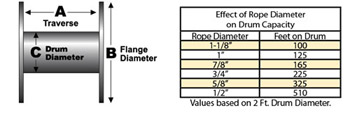

Boom Sheave Recommendations

|

To ensure maximum efficiency and safety, the boom sheave diameter should be no less than eight times the rope diameter for braided ropes and ten times the rope diameter for twisted and plaited ropes. The sheave groove diameter should be no less than 10% greater than the rope diameter and the sheave groove should be round in shape, NOT “V” shaped. Ensure sheaves are free to rotate. Larger sheave diameters will provide longer rope service life.

|

|

Avoid Kinking and Hockling

The continuous use of 3 strand and 4 strand lines on one side of a winch or windlass is a common abuse that can render a line useless in a short time. Repeated hauling of a line over a winch in a counterclockwise direction will extend the lay of the rope and will simultaneously shorten the twist of each strand. As this action continues, kinks or hockles will develop. Once hockles appear, they cannot be removed and the rope is permanently damaged.

If the line is continuously hauled over a winch in a clockwise direction, the rope lay is shortened and the rope becomes stiff and readily kinks.

To avoid detrimental conditions, the direction of turns over the winch should be alternated, regularly. If this practice is observed, the original rope balance will be maintained and the lines will have a much longer, useful service life. Clockwise turns are recommended for the initial use of a new line.

Excessive turns can cause kinking on any rope, but hockles can occur only in the basic “twisted” ropes, i.e., 3 strand, 4 strand and wire ropes. Braided and plaited ropes cannot be hockled; their inter-locking strand construction prevents unlaying. Strands in braided and plaited ropes run in both directions creating a torque-free balance, thus eliminating any inherent tendency toward twist or rotation. Swivels can be used safely, but are seldom necessary.

When marrying a braided rope to a twisted line and/or to wire rope, the twisted line can impart its twist to the braided line if the ropes are married without a swivel between the two different line constructions. When marrying a braided rope to a twisted line and/or to wire rope, the twisted line can impart its twist to the braided line if the ropes are married without a swivel between the two different line constructions.

A braided or plaited rope, being torque free can have twist induced by constant working on winches. If a twist develops, it can be removed by “counter-rotating” the rope when it is relaxed.

Eye Splices

Eye splices at the end of winch lines that are not factory installed must be done in strict accordance with the steps and procedures outlined in the Samson Splicing Instruction Manual. These splicing methods can be learned and executed by line crews, shop personnel and marine users. Assistance in splicing instruction is available through the Samson Technical Representative in your area. Splicing training kits, manuals and tools can be supplied by us and instructions are on line at www.samsonrope.com

The standard eye splice cannot be pulled out under tension; however, it can be pulled out by hand when the winch line is in a relaxed state. To prevent such tampering, it is recommended that lock stitching or a tight seizing be applied to the base or throat of the splice.

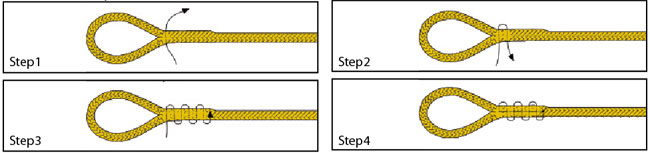

Lock Stitching Eye Splices

Lock stitching may prove advantageous on some splices to prevent no-load opening due to mishandling. Material required: One fid length of nylon whipping twine approximately the same size diameter as the strand in the rope being lock stitched. You can also use the strands that are cut from the rope, but whipping twine is preferable. Instructions are available on line and can be mailed or faxed to your location.

Knots

Splicing is by far, the strongest and most efficient means of attachment. Knots should never be tied in a winch line, as knots reduce the strength of any rope by as much as 50%. Also, sharp bends in the line will also greatly reduce rope strength and should be avoided.

Shock Loading

Shock loading of any line produces a drastically different set of physical properties and results as compared with normal loading. Shock loading is a jerking or snatching of a line or a very sudden change in tension, going from a relaxed state (low load) to a high load. Shock loading results in accelerated wear of the rope.

A typical shock load on a winch line occurs when an object is lifted vertically with a sudden jerk or when a load is suddenly dropped. A 5,000 Lbs. load suddenly dropped could develop impact loading exceeding 30,000 Lbs. resulting in winch line failure. 4 inch sudden drops can actually double the loading on the winch line. Similarly, an over wrap “falling off” the winch drum can result in doubling the actual loading on the winch line.

Assigned Design Factors

|

Assume that you have seven identical ropes, each with 30,000 Lbs. break strength and the ropes are worked at different loads in a winch line application.

The chart clearly shows that a higher design factor results in greater service life and safety. If the same amount of weight is to be lifted and a rope with a greater Work Load Limit is used the rope will last longer than rope used at a lower Work Load Limit.

Training

A safety training and preventative maintenance program in the use of winch lines is strongly recommended.

Used and cared for properly, Samson Winch Lines will provide an economical and trouble free service life. Samson guarantees all its products against manufacturing defects, but cannot be held liable for failure or accident due to improper use or failure to observe prescribed procedures for usage.

|

|

Scenario Number

|

Breaking Strength (Lbs.)

|

Work Load Limit (Lbs.)

|

Design Factor

|

Number of Lifts Before Failure

|

|

1

|

30,000

|

5,000

|

6:1

|

1,000

|

|

2

|

30,000

|

6,000

|

5:1

|

750

|

|

3

|

30,000

|

7,500

|

4:1

|

500

|

|

4

|

30,000

|

10,000

|

3:1

|

300

|

|

5

|

30,000

|

15,000

|

2:1

|

100

|

|

6

|

30,000

|

20,000

|

1.5:1

|

25

|

|

7

|

30,000

|

28,000

|

1.07:1

|

5

|

|

Pre Spliced Winch Lines

Winch lines can be pre-spliced with one or two eyes in the listed products.

|

Winch Lines

|

Lengths

(Feet)

|

Diameters

(Inches)

|

|

AmSteel®

|

50 - 175

|

3/8 - 1-1/8

|

|

AmSteel® Blue

|

50 - 175

|

3/8 - 1-1/8

|

|

AmSteel® II Plus

(Coated and Uncoated)

|

50 - 175

|

1/2 - 1-1/4

|

|

AmSteel® II

(Coated and Uncoated)

|

50 - 175

|

1/2 - 1-1/4

|

|

Stable Braid

(Coated and Uncoated)

|

50 - 175

|

1/2 - 1-1/4

|

|

|

|