|

Four, identical, single ply slings were fabricated from a single roll of webbing. All independent variables were controlled, as the same thread, machine and fabricator were used for this experiment. The slings (EE1-903) are rated at 4800 Lbs. vertical and we would expect 24,000 Lbs. break strength. The slings were pulled to destruction. The control sling broke at 26,050 Lbs. The other three slings were deliberately cut on one edge to simulate: 1/8 inch, 1/4 inch and 3/8 inch cuts. This seemingly “minor” damage resulted in very significant strength loss.

“Minor” damage is extremely serious and damaged slings must be removed from service, immediately and not used for other applications. Remember, there is ZERO tolerance for sling damage. Be pro-active and prevent sling damage from occurring by employing suitable Sling Protection.

|

Patented Back-Up Protection

|

|

Twin-Path® slings are actually two complete yet separate slings in one. Each path accounts for 50% of the total sling Work Load and makes its own separate connection between the hook and the load. Twin-Path® slings provide sling users redundant, back up protection.

|

|

|

|

Easy Inspection

|

|

Twin-Path® slings provide sling users with an early warning inspection system. The load bearing core yarn is encapsulated by Covermax® or polyester covers and does not contact the load. Cornermax® is made from a double layer industrial nylon material. If you see the inner, red cover, remove the sling from service and return it for repair evaluation.

|

|

|

|

Tattle Tails

|

|

Before each use, inspect the entire sling. Tattle Tails are not a precision force measurement device. Tattle tails are an extension of the load bearing core yarns. Tattle Tails will retract and eventually disappear as the sling is severely overloaded. Tattle Tails must extend past the tag area of the sling. Both Tattle Tails must be visible; if not, remove the sling from service for repair evaluation. If Tattle Tails or any part of the sling shows evidence of chemical degradation, remove it from service for repair evaluation.

|

|

|

|

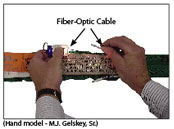

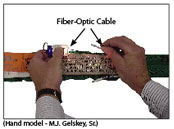

Fiber-Optic Inspection System

|

|

Only Twin-Path® Slings have a Fiber-Optic Inspection System. Fiber Optic Inspection assists sling users and inspectors in evaluating the condition of the load bearing core yarns. Core Yarn condition can be inspected by checking Fiber Optic cable conductivity. If Core Yarn has suffered chemical, heat or crushing damage, fiber optic cables will lose the ability to transmit light from one end to the other. Lack of light conductivity gives the inspector a reason to remove the sling from service and return it for repair evaluation. Fiber Optic cables will conduct light from overhead sources or flashlights. The inspector simply covers and removes a finger from one cable end and watches the other cable end for blinking, indicating conductivity. Fiber Optic Inspection combined with thorough visual and hand over hand inspection techniques provides inspectors the assurance slings are acceptable for use.

US Patent No. 5,651,572

|

|

|

|

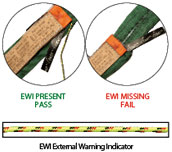

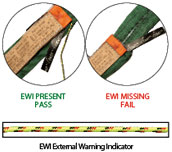

?Check-Fast Inspection System

|

|

?Check-Fast® Inspection provides users and inspectors a pass/fail inspection system for evaluating load bearing core yarn condition. Damage to core yarn from fiber on fiber abrasion, UV degradation and severe overload can be detected. The ?Check-Fast® tag and External Warning Indicator (EWI) make up the ?Check-Fast® Inspection System. If accidental overload beyond rated capacity occurs, the External Warning Indicator (EWI) will disappear before the sling fails. Sling users and inspectors now have an objective pass/fail inspection system that is not subjective. The ?Check-Fast® Inspection System combined with visual and tactile inspection techniques provides improved job site safety. Specify Check-Fast® by adding CF to the stock number, i.e., TUFXKS 4000 CF.

US Patent No. 7,661,737

|

|

|

|

Slings can fail if damaged, misused, or overloaded. Inspect before use. Damaged slings shall not be used. Do Not Exceed Rated Capacity. Protect sling from being cut by load edges, protrusions, corners and abrasive surfaces. Avoid exposure to damaging chemicals and temperatures over 180 degrees (F). DEATH or INJURY can occur from improper use or maintenance. Slings can fail if damaged, misused, or overloaded. Inspect before use. Damaged slings shall not be used. Do Not Exceed Rated Capacity. Protect sling from being cut by load edges, protrusions, corners and abrasive surfaces. Avoid exposure to damaging chemicals and temperatures over 180 degrees (F). DEATH or INJURY can occur from improper use or maintenance.

|

|

|