|

The The  Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations. Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations.

It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous. It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous.

The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard clearly establishes the requirement for training. Section 9-1.1-Training states, “Chain sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.” The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard clearly establishes the requirement for training. Section 9-1.1-Training states, “Chain sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.”

All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations. All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations.

Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others.

Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained. Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained.

|

|

Any hazardous condition disclosed by an inspection shall require sling replacement. Temporary repairs are not permitted. Damage and wear seriously reduce sling Work Load Limits.

Always know the load weight and select the appropriate sling for the load, configuration of lift necessary to ensure load control and any chemical exposure.

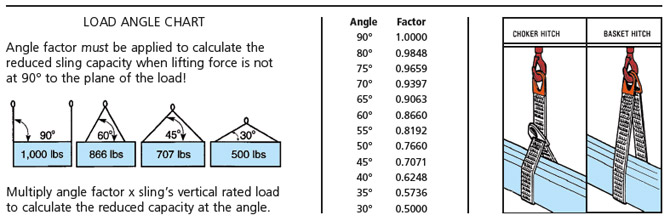

Always take into account sling angles to calculate changes in the sling Work Load Limits, when used in choker and non-perpendicular vertical, basket or bridle configurations.

Ensure that the load will not cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces with suitable materials of sufficient strength, thickness and construction.

The strength of Chain Slings can be affected by chemically active environments. Sling materials may be susceptible to damage from caustic or acid substances or fumes. Strong oxidizing environments attack all common sling materials and components. Consult the manufacturer prior to selection and use.

Do not use Wire Mesh Slings in pairs, unless used vertically and attached to a spreader bar. Do not use Wire Mesh Slings in pairs, unless used vertically and attached to a spreader bar.

Maximum Operating temperature for coated wire mesh slings is 150°(F)/65°C. Maximum Operating temperature for coated wire mesh slings is 150°(F)/65°C.

|

|

|

| INSTRUCTIONS FOR CARE, USE, INSPECTION, & REPAIR |

CARE

Store on a rack away from possible mechanical damage, corrosion, moisture, dust, grit and extreme temperatures Do not hammer sling to straighten or force a spiral or cross rod into position.

USE

Know the weight of load. Check tag to confirm that sling is rated adequately for the load (see load angle chart). Avoid twists, knots or kinks. Be sure that the load cannot cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces; use materials of sufficient strength, thickness and construction. Distribute load evenly across width of mesh. Balance the load. Maintain load control. Avoid jerking the load. Be alert for snagging of load. Do not pull on stuck objects. Avoid dragging sling over rough surfaces and from under the load. Use between -20° & 550°F (uncoated), 0° & 150°F (elastomer coated). Use only in a vertical, vertical basket or choker hitch (if fitted with a choker triangle). Choker hitch must choke on mesh, never on end fitting. Stand clear of load at all times. Persons are not to ride on sling or load.

INSPECTION

Before each use: Check that rated loads are marked on end fitting. Inspect for broken edge welds/brazed joints, broken wires, lack of flexibility, wire diameter reduced 25% from wear or 15% by corrosion. Check end fittings for reduction in eye opening more than 10%. Check triangle choker fitting slot for more than 10% increase in depth. Check fittings for cracks, twisting, and elongation. If this wear or damage is present, or rated load is missing or Illegible, remove from service and repair or replace sling.

Frequent inspection is done by the person handling the sling before each use and must include all of the before use items. Periodic Inspections are required at least annually for normal service, quarterly or more frequently if in severe service or nearly constant use. Periodic inspections are performed by designated person(s) who are trained and a written record of the most periodic inspection shall be maintained. The inspector shall determine when further use would be hazardous.

REPAIR

Any hazardous condition disclosed by an inspection shall require repair or replacement. Field repair is not permitted. Only manufacturers or authorized centers may make repairs. All repaired slings must be proof tested and certified.

|

|

|

Because of the reduced lifting capacity, use extra care when the sling to load, also known as the horizontal angle, is less than 45° and do not make lifts of less than 30° load angle. Example: A sling with adequate capacity could be broken because of increased tension resulting from angles of less than 30 degrees. When possible, use longer slings to minimize angular tension by increasing the angle.

|

| Wire Mesh Slings Overview |

|

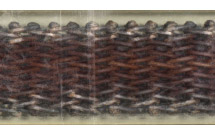

Lift-It® is the Western Regional Service Center for Cambridge International. Lift-It® Wire Mesh Sling Welded Edge construction will outlast and outperform brazed edges, offered by others. Our Wire Mesh slings are fabricated in a timely manner and you will receive the same service level that you have come to know and expect.

The unique woven wire construction of Lift-It® Wire Mesh Slings consists of a series of smooth, spiral wires joined together across the sling body. This construction gives mesh slings flexibility and long life. Standard mesh materials are high strength, Carbon Steel (10 or 12 gauge), 4130 Heat Treated Alloy Steel and Stainless Steel (Type 304).

Lift-It® Wire Mesh Slings are widely used in metal working applications and are ideal for positioning coiled strip for slitting and for handling sheet steel, hot rolled flat bar stock and cold drawn flats. Other applications include the efficient handling of pre-stressed concrete, pre-fabricated wall panels and pre-cast hollow core concrete beams.

Lift-It® Wire Mesh Slings are recommended for use where loads are hot, abrasive or tend to damage synthetic slings. Wire Mesh Slings grip the load with little stretch and withstand temperatures to 550°(F)/287°(C).

|

| SLING AND HARDWARE SPECIFICATIONS |

|

|

WORK LOAD LIMITS

|

|

|

|

MESH

WIDTH

|

Choker

|

Basket Hitches

|

|

|

90°

|

60°

|

45°

|

Sling Wt. (Lbs.)

|

Terminal Dimensions (Inches)

|

|

3 Ft. Sling

|

Adder

Per Ft.

|

"A"

|

"B"

|

"C"

|

|

|

2

|

1,600

|

3,200

|

2,700

|

2,200

|

5

|

1.25

|

1-3/4

|

4

|

6

|

|

3

|

3,000

|

6,000

|

5,100

|

4,200

|

8

|

1.88

|

2-1/2

|

5-1/4

|

7-1/2

|

|

4

|

4,400

|

8,800

|

7,600

|

6,220

|

10

|

2.50

|

2-1/2

|

5-1/2

|

7-3/4

|

|

6

|

6,600

|

13,200

|

11,430

|

9,300

|

15

|

3.88

|

2-3/4

|

6-1/2

|

9

|

|

8

|

8,800

|

17,600

|

15,000

|

12,400

|

20

|

5.13

|

4

|

8-3/4

|

12

|

|

10

|

11,000

|

22,000

|

19,050

|

15,550

|

26

|

6.38

|

3-1/2

|

7-3/4

|

10-3/4

|

|

12

|

13,200

|

26,400

|

22,860

|

18,660

|

33

|

7.63

|

3-1/2

|

8

|

11-1/4

|

|

14

|

15,400

|

30,800

|

26,670

|

21,775

|

47

|

8.78

|

4-1/2

|

10-5/8

|

14-11/16

|

|

16

|

17,600

|

35,200

|

30,480

|

24,886

|

55

|

10.12

|

4-1/2

|

11-1/4

|

15-9/16

|

|

18

|

19,800

|

39,600

|

34,290

|

27,990

|

64

|

11.38

|

4-1/2

|

11-7/8

|

16-9/16

|

|

20

|

22,000

|

44,000

|

38,100

|

31,100

|

73

|

12.75

|

4-1/2

|

12-1/2

|

17-9/16

|

|

| CHEMICAL AND ENVIRONMENTAL INFORMATION |

|

Metal Mesh Composition

|

Weak

Sulfuric Acid

|

Weak

Hydrochloric Acid

|

Alkaline Caustic Solutions

|

Salt

Solutions

|

Organic Solvents

|

Water

|

|

Carbon Steel

|

No

|

No

|

No

|

No

|

Yes

|

No

|

|

T-304 Stainless Steel

|

No

|

No

|

Yes

|

No

|

Yes

|

Yes

|

|

AISI 4130 Alloy Steel*

|

No

|

No

|

No

|

No

|

Yes

|

No

|

|

Urethane-Coated

|

No

|

Yes

|

No

|

Yes

|

No

|

Yes

|

*Heat Treated

The above chart provides general guidelines and all data listed is based upon a 70 degree (f) exposure. For specific time, temperature and concentration factors, consult us prior to purchase or use.

|

| REPAIR AND CERTIFICATION |

|

All newly manufactured Lift-It® Wire Mesh Slings are proof tested to twice vertical Work Load Limit. Each sling is assigned a unique serial number and supplied with proof test certification.

Lift-It® Manufacturing will repair and certify all types and brands of Wire Mesh Slings. Repairs are charged on a material and labor basis, after a thorough sling inspection. All repaired slings are tested to twice vertical Work Load Limit and certified.

|

| SPECIAL COVERINGS |

|

For maximum load protection, consider Coated Wire Mesh Slings. Soft, smooth, elastic coverings enhance the gentleness and service life of slings and improve ease of handling. Coverings increase sling thickness approximately 5/16” and flexes to a radius as small as 2 inches.

Maximum operating temperatures for Coated Wire Mesh Slings is 150°(F)/65°(C). Maximum operating temperatures for Coated Wire Mesh Slings is 150°(F)/65°(C).

|

|

URETHANE COVERING

Urethane Covering is well known for its flexibility, without checking, toughness and its long service. Urethane is resistant to attack by lower concentrations of: nitric, sulfuric, hydrochloric acids, hydrofluoric acids and sodium hydroxide.

|

|

NEOPRENE COVERING

Neoprene is resistant to attack by oils, greases, stronger concentrations of sodium hydroxide, sulfuric acid, hydrochloric acid and hydrofluoric acid.

|

|

| REMOVAL FROM SERVICE CRITERIA |

|

HOW TO ORDER |

|

Slings must be inspected before each use and shall be removed from service if any of the following defects are present:

|

- Missing or illegible sling dentification.

- Broken weld along the sling edge.

- Broken wire in any part of the mesh.

- A reduction in wire diameter of 25% due to abrasion or 15% from corrosion.

- Lack of flexibility due to mesh distortion.

- Distortion of the choker fitting so the depth of the slot is increased by more than 10%.

- Distortion of either fitting so the width of the eye opening is decreased by more than 10%.

- 15% reduction of the original cross sectional area of any point around the hook opening.

- Visible distortion of either fitting out of its plane.

- Cracked end fittings.

- Slings with locked spirals or without free articulation or move-ment.

- Fittings that are pitted, corroded, cracked, bent, twisted, gouged or broken.

- Other conditions, including visible damage, that cause doubt as to the continued use of the sling.

|

|

|

DETERMINE SLING STOCK NUMBER

|

- Select the Sling Material:

Carbon Steel , Alloy or Stainless.

- Select sling type:

Type 1-Choker or Type 2-Basket.

- Specify gauge for carbon steel.

- Specify mesh width: Inches.

- Specify sling length: Feet (Overall).

|

|

|

|