USAGE

Handling: Never stand in line with a rope under tension.

If a rope fails it can recoil with lethal force. Synthetic rope has higher recoil tendencies than natural fiber rope. Reverse rope ends regularly, which permits even wearing and ensures a longer, useful life. When using tackle or slings, apply a steady, even pull, to get full rope strength.

Overloading and Use of Work Load Limits

Because of the wide range of uses for rope, exposure to factors affecting rope behavior and the degree of risk to life and property involved, it is impossible to make blanket recommendations about Work Load Limits. However, to provide guidelines, Work Load Limits are calculated for rope in good condition with appropriate splices, in non-critical applications and under normal service conditions.

A higher Work Load Limit may be selected only with expert knowledge of conditions and professional estimate of risk; if the rope has not been subjected to dynamic loading or other excessive use; if the rope has been inspected and found to be in good condition and is to be used in the recommended manner; and if the application does not involve elevated dynamic loading (see explanation below) such as sudden drops, snubs, or pickups. For all such applications and for applications involving more serious exposure conditions or for recommendations on special applications, consult the manufacturer. Many uses of rope involve serious risk of injury to persons or damage to valuable property. Workers should never be under a suspended load. An equally dangerous situation occurs if persons are in line with a rope under tension; should the rope fail, it may recoil with lethal force. Persons should be warned against the serious danger of standing in line with any rope under tension.

In all cases where such risks are present, or there is any question about the loads involved or the conditions of use, the Work Load Limit should be substantially reduced and the rope properly inspected.

Minimum Break Strength is based upon test data of new, unused rope and is a value not greater than two standard deviations below the mean.

Dynamic Loading Voids Work Load Limits

Normal Work Load Limits are not applicable when rope is subject to significant dynamic loading. Instantaneous changes in load up or down, in excess of 10% of the line’s rated Work Load Limit constitutes hazardous shock load and would void normal Work Load Limits. Whenever a load is picked up, stopped or swung, there is an increased force due to such dynamic loading. The more rapidly action occurs, the greater the increase will be. In extreme cases, the force put on the rope may be two, three or even more times the normal Work Load involved and may result in the rope breaking. Examples could be picking up a tow on the slack line or using a rope to stop a falling object. Therefore, in all such applications: towing lines, lifelines, safety lines, climbing ropes, etc. Work Load Limits as given DO NOT APPLY.

|

|

COMPUTING ENERGY ABSORPTION REQUIREMENTS

Users should be aware that dynamic forces are greater on a low-elongation, high modulus, aramid rope and less on a higher elongation nylon rope. Dynamic forces are greater on a shorter rope than on a longer one. Work Load limits contain provision for very modest dynamic loading. This means, however, that when the Work Load Limit has been used to select a rope, the load must be handled slowly and smoothly to minimize effect and avoid exceeding provision for them.

Example: A load of 3,500 Lbs. is being lowered using 5/8 in. diameter, Double Esterlon, which has a maximum recommended Work Load Limit of 3,060 Lbs. With 15 feet of line in tension, the line accidentally slips, dropping the load one foot before arresting the fall.

Questions: How much energy did the rope have to absorb? What was the maximum load on the rope? Has the rope been overloaded or damaged?

Data:

Work done (Ft. Lbs.) – (Weight)(Length of Fall) = 3,500 Ft. Lbs.

Assuming Double Esterlon has a working energy absorption capacity of 291 ft. Lbs. per pound of rope and a weight of 13.7 Lbs. per 100 ft., or .137 Lbs./ft.

Rated Maximum Working Energy Absorption Capacity of:

16 ft. of 5/8” Double Esterlon =

(16 ft.)(.137 Lbs./Ft.)(291 Ft. Lbs./Lbs.) = 638 Ft. Lbs.

In this example:

2.19 Lbs. of rope (16 ft. x .137 Lbs./ft.) in use must absorb:

3,500 Ft. Lbs. or 3,500 ÷ 2.19 Lbs. =1,596 Ft. Lbs./Lbs. of rope.

In this example the maximum working energy absorption capacity has been exceeded by nearly six (6) times. The effect is to drive the maximum load the rope encounters until it arrests the load or breaks.

Ultimate energy absorption of 5/8” x 16 Ft. Double Esterlon = (16 Ft.)(.137Lbs./Ft.)(7,711 Ft. Lbs./Lb.)=16,902 Lbs.

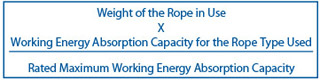

Any dynamic load beyond this would break the line. There is a linear relationship between the weight of the rope in tension versus rope energy absorption capability. In the above example, some degree of the rope integrity has been compromised and prudent safety practices would dictate for discarding the line.

A short film on this subject may be viewed at

www.yalecordage.com/videos

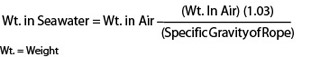

Computing Weight in Seawater:

|