Actek® Safety and Warning Information

|

Actek® products are intended for use only by trained, qualified and experienced personnel. Misuse of any Actek® product or lack of supervision and inspection can lead to serious accidents including death. Actek® has always stressed that safety is of utmost importance.

Prior to any use of Actek® product, evaluation of the product application, safety precautions, Work Load Limits and control of all field conditions is mandatory. Prevent applications that exceed the Work Load or any other product misuse. Actek® cautions that all design factors shown are approximate and apply to new and unused or in

“as new” condition products. Work Load Limits should never be exceeded under any circumstance.

If you have any questions about the proper use or installation of any Actek® product, please call (800) 752-7229.

Safety Notes

Actek® ensures that all materials meet or exceed the safety requirements for lifting. Work Loads are based upon a new or in “as new” condition product. Work Load is considered to be the greatest load that should be applied to an item at any time.

INSPECTION & MAINTENANCE

|

In order to ensure safe lifting, Actek® products must be properly used and maintained. Hoist rings may be subject to wear, corrosion, deformation, overloading and other limiting factors which may affect the Work Load Limits. Prior to use, the product should be regularly inspected to determine if it may be used or whether it should be removed from service. It is the responsibility of the user to inspect all lifting units for signs of wear and to discard any parts showing visible signs of wear. Every user should establish a safety inspection program for routine visual inspection of all products to determine whether damage (e.g. cracks, corrosion and deformation) is present. A product inspection schedule should be established based upon factors such as frequency of use, period of use and environment. In addition to the regular safety inspection, the following safety directives must be followed:

|

- Prior to use, always inspect hoist rings for possible wear or damage. Never use hoist rings that show any sign of wear or damage.

- Never use hoist rings if bail is bent or elongated.

- Prior to use, threads must be clean, undamaged and must fit properly.

- Always install hoist rings using the listed torque value. Periodically check torque because screws could loosen during service.

- Bent bolts should be discarded or replaced with bolts of proper size and grade. Never straighten bent bolts; it may lead to serious injury or death.

|

- Never use washers or any spacers between bushing and mounting surface.

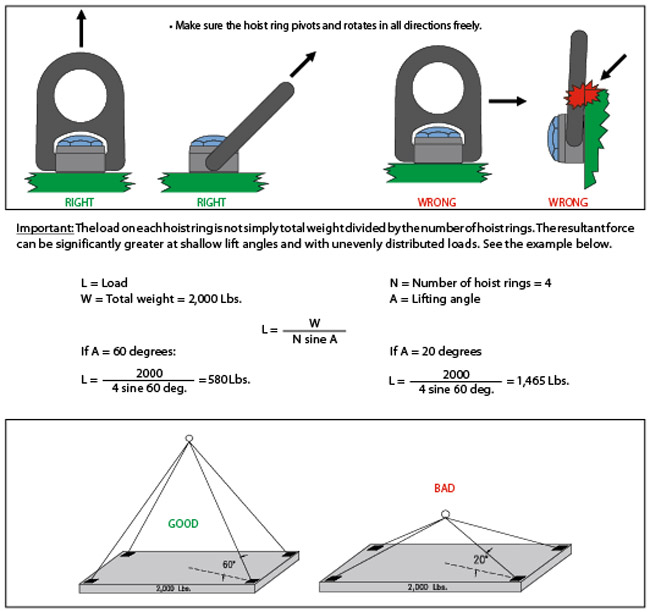

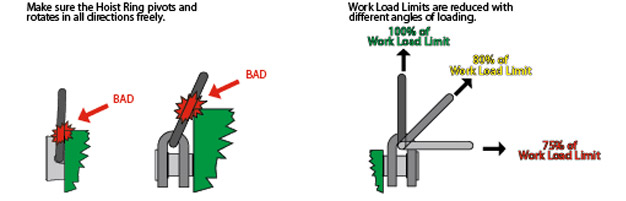

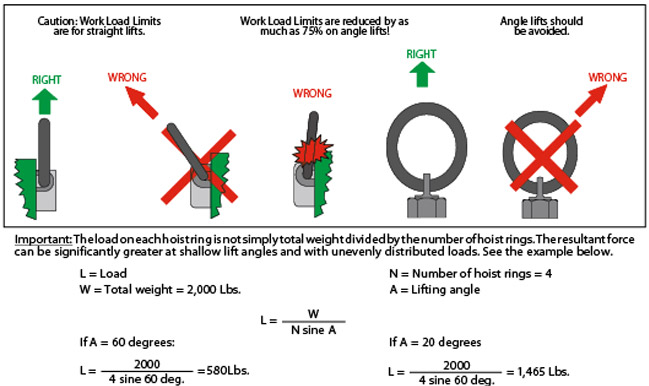

- Always make sure the hoist ring pivots and rotates in all directions freely.

- Never use hoist rings near or around corrosive materials.

- If hoist ring is exposed to extreme temperatures (hot or cold), please contact our engineering department for suggestions/consultation.

- Work Load Limits should never be exceeded under any circumstance.

|

|

If there are questions regarding the replacement or repair of worn Actek® products, please contact us.

|

IMPORTANT INFORMATION: READ, UNDERSTAND AND FOLLOW.

|

- ALWAYS READ SAFETY PRECAUTIONS PRIOR TO USE OR INSTALLATION.

(Safety Precaution included with every hoist ring).

- ALWAYS INSPECT THE HOIST RING BEFORE EACH USE.

- Regularly inspect all hoist ring parts.

- Always tighten the bolt to the recommended torque value.

- Always make sure that the hoist ring is free to pivot and swivel in all directions.

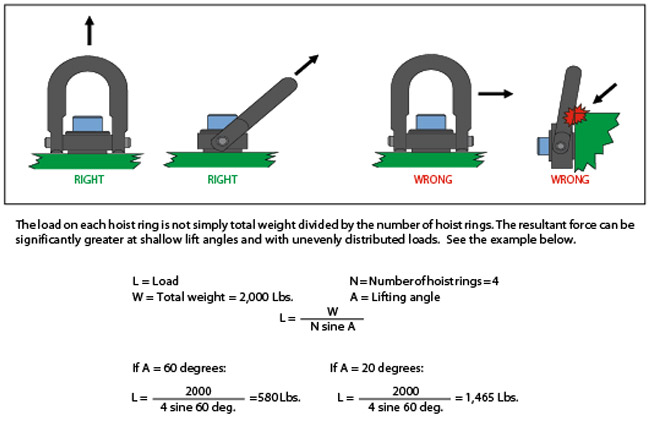

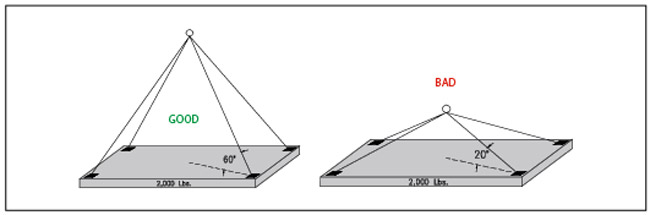

- Always choose a hoist ring with the proper load rating. See the “Actual Load” equation to help you choose the appropriate hoist ring.

- Always make sure that the bushing of the hoist ring sits flush against the object being lifted.

- Install hoist rings in materials that have a tensile strength of at least 80,000 psi.

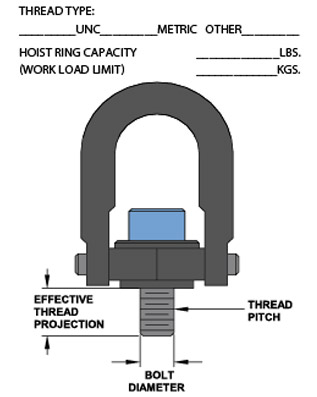

- Always make sure the thread engagement is at least 1.5 times the diameter of the hoist ring bolt.

- When installing a hoist ring in a through-hole with a nut and washer, make sure to use a Grade 8 nut that has full thread engagement.

- Consider periodic load-testing as an extra precaution.

- NEVER EXCEED WORK LOAD LIMITS.

- NEVER APPLY SHOCK LOAD.

- Never use a hoist ring that you believe is damaged.

- Never use a hoist ring that has damaged threads on the bolt.

- Never use a hoist ring in an application where it does not pivot and swivel in every direction freely.

- Never use a hoist ring that is not tightened to the recommended torque.

- Never replace the components of the hoist ring with anything other than parts recommended by Actek®.

- Never use a hook larger than the diameter of the hoist ring opening.

- Never shim or use washers between the hoist ring and surface of object being lifted.

|

|

HOIST RING INSPECTION & MAINTENANCE

ALWAYS INSPECT THE HOIST RING BEFORE EACH USE. MAKE SURE:

|

- The bolt is tightened to the recommended torque.

If the bolt is not tightened, the threads may be stripped during lifting.

- The bushing of the hoist ring sits flush against the object being lifted.

This ensures the recommended torque puts the proper preload onto the hoist ring allowing the hoist ring to reach its full Work Load Limit.

- The hoist ring is free to swivel and pivot in every direction.

If the hoist ring binds up in any direction, it should be removed from service.

- There are no signs of corrosion.

Corrosion can cause deterioration to the hoist ring material allowing for fatigue or cracking to take place. Corrosion can also prevent the hoist ring from pivoting and swiveling freely.

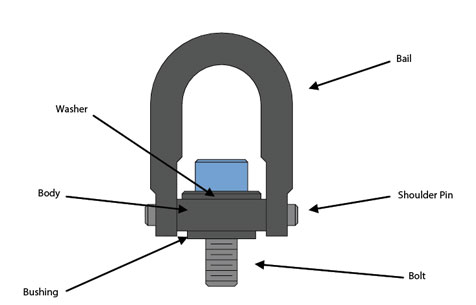

- There are no signs of wear or cracks, especially on the bolt, shoulder pins and bail.

Damage or wear on the bolt head, shoulder pins or bail may be an indication that the hoist ring is coming into contact with obstructions during use. Contact with obstructions should be avoided as it can cause binding and shock loads which exceed the rating of the hoist ring.

- The shoulder pins are secure and do not rotate or come loose.

Check by using pliers to rotate the shoulder pins by hand. If the shoulder pin rotates, it is no longer securely in place and could come loose causing the hoist ring to break.

|

|

|

|

NEVER EXCEED WORK LOAD LIMIT

|

|

|

|

IMPORTANT INFORMATION: READ, UNDERSTAND AND FOLLOW.

|

|

|

Lifting Angle

(Degrees)

|

Number of

Hoist Rings

|

Weight of Load

(Lbs.)

|

Actual Applied Load on

Hoist Ring (Lbs.)

|

|

90

|

4

|

2,000

|

500

|

|

80

|

4

|

2,000

|

510

|

|

70

|

4

|

2,000

|

535

|

|

60

|

4

|

2,000

|

580

|

|

50

|

4

|

2,000

|

655

|

|

40

|

4

|

2,000

|

780

|

|

30

|

4

|

2,000

|

1,000

|

|

20

|

4

|

2,000

|

1,465

|

|

|

|

|

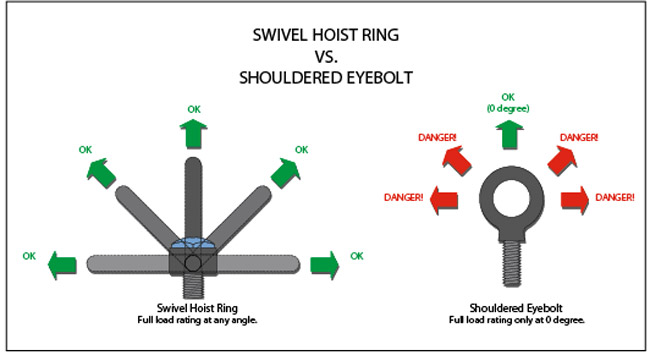

Eyebolts have been used for over 100 years and have performed well when used properly, meaning the direction of loading must be at zero degrees. If the load shifts or the direction of loading on the eyebolt is as much as 10 degrees off the zero line of force, the result is a bent eyebolt. Eyebolts have been used for over 100 years and have performed well when used properly, meaning the direction of loading must be at zero degrees. If the load shifts or the direction of loading on the eyebolt is as much as 10 degrees off the zero line of force, the result is a bent eyebolt.

When you bend the eyebolt, it is broken!

You can’t see the break most of the time. If you examine the bent area using x-ray techniques, you will find the damage. Continued use of a bent eyebolt may result in failure at very little weight.

Swivel Hoist Rings are designed for lifting at any angle because they can swivel 360º and pivot 180º. Therefore, the rated load remains the same, regardless of the angle of force. As a result, you increase safety and peace of mind.

|

|

HOIST RINGS SAFETY PRECAUTIONS: Swivel, Forged and Stainless

|

|

PRIOR TO USING ANY HOIST RING, PLEASE READ THE FOLLOWING FOR PROPER INSTALLATION AND USAGE.

|

|

As with all mechanical devices, regular inspection for wear and strict adherence to use instructions is necessary to prevent misuse and failure.

|

- Despite the 5:1 design factor, NEVER EXCEED THE WORK LOAD LIMIT. The design factor is needed in case of misuse, which could drastically lower load capacity.

- Tighten mounting screws to the recommended torque. Periodically check torque because bolts could loosen during service.

|

|

|

|

|

|

HOIST RINGS SAFETY PRECAUTIONS:

Side Load, Lifting Ring, Side Pull, Ultra and Large Opening

|

|

PRIOR TO USING ANY HOIST RING, PLEASE READ THE FOLLOWING FOR PROPER INSTALLATION AND USAGE.

|

|

As with all mechanical devices, regular inspection for wear and strict adherence to use instructions is necessary to prevent misuse and failure.

|

- Despite the design factor, NEVER EXCEED THE WORK LOAD LIMIT. The design factor is needed in case of misuse, which could drastically lower load capacity.

- Tighten mounting screws to the recommended torque. Periodically check torque because bolts could loosen during service.

|

|

|

|

|

IMPORTANT INFORMATION FOR SIDE LOAD HOIST and LIFTING RINGS

|

|

IMPORTANT INFORMATION FOR SIDE PULL, ULTRA and LARGE OPENING HOIST RINGS

|

|

|