|

Load DISENGAGEMENT can cause DEATH OR INJURY. DISENGAGEMENT results from misuse, damage and excessive wear. Load DISENGAGEMENT can cause DEATH OR INJURY. DISENGAGEMENT results from misuse, damage and excessive wear.

Never use a hook without training.

OSHA regulation requires responsible work practices. “The employer shall permit only those employees qualified by training or experience to operate equipment and machinery.” OSHA 1926.20 (b) (4)

Employee training should include information given in OSHA training literature, ASME B30.9 “Slings” and ASME B30.10 “Hooks” safety standards and this document.

Always inform yourself and ask your employer for hook safe use instruction.

“The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” OSHA 1926.21 (b) (2).”

ASME B30.10-1.3 states, “It shall be determined that the weight of the load to be lifted does not exceed the lesser of the load rating of the hook or the load rating of the equipment of which the hook is a part.”

The maximum load applied to self-locking hooks must be known for proper self-locking hook selection.

Never use a hook without a legible product identifier.

Product Identification is required to ensure proper application.

OSHA 1910.184 (e)(2)(i) stipulates, “Hooks, rings or other attachments shall have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling shall not be used in excess of the rated capacity of the weakest component.”

Gunnebo Lifting product identifiers are forged into self-locking hooks and designate trade size followed by the grade, Example: 13-8

Gunnebo Lifting Grade 80 and Grade 100 Alloy Steel BK self-locking hook Work Load Limits for selected design factors are listed in pounds and given in TABLE 1A and TABLE 1B.

Never overload a hook.

Understand Work Load Limits.

OSHA 1910.184 (c)(4) states, “Slings shall not be loaded in excess of their rated capacities.”

|

TABLE 1A

|

|

GR 80 ALLOY STEEL BK SELF-LOCKING HOOK

Work Load LimitS (Lbs.)*

|

|

TRADE SIZE

|

DESIGN FACTOR

|

|

MM

|

IN

|

4:1

|

5:1

|

6:1

|

9:1

|

|

5/6

|

7/32

|

2100

|

1680

|

1400

|

930

|

|

7/8

|

9/32

|

3500

|

2800

|

2330

|

1560

|

|

10

|

3/8

|

7100

|

5680

|

4730

|

3160

|

|

13

|

1/2

|

12000

|

9600

|

8000

|

5330

|

|

16

|

5/8

|

18100

|

14480

|

12070

|

8040

|

|

18/20

|

3/4

|

28300

|

22640

|

18860

|

12570

|

|

22

|

7/8

|

34200

|

27360

|

22800

|

15200

|

|

26

|

1

|

47700

|

38160

|

31800

|

21200

|

|

28

|

1-1/8

|

55100

|

44080

|

36700

|

24480

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

OSHA 1910.180 (h) (3) (v) states, “No hoisting, lowering, swinging or traveling shall be done while anyone is on the load or hook.”

OSHA 1926.550(g)(2) stipulates: “The use of a crane or derrick to hoist employees on a personnel platform is prohibited, except when the erection, use and dismantling of a conventional means of reaching the worksite, such as a personnel hoist, ladder, stairway, aerial lift, elevating work platform or scaffold, would be more hazardous or is not possible because of structural design or worksite conditions.”

“Bridles and associated rigging for attaching the personnel platform to the hoist line shall be used only for the platform and the necessary employees, their tools and the materials necessary to do their work and shall not be used for any other purpose when not hoisting personnel.” OSHA 1926.550 (g) (4) (iv) (E)

Alloy steel BK self-locking hooks may be used to rig personnel platforms when lift system is in full compliance with OSHA 1926.550 (g).

Never rig a hook to a load improperly and avoid dropped loads and hook damage.

See: OSHA 1910.184 (c), ASME B30.5-3.2,

ASME B30.9-1.10, 2.10, 3.10, 4.10, 5.10 and 6.10.

Loads shall be centered in the base (bowl/saddle) of hook to prevent point loading of the hook.

(See Figures 1a, 1b and 1c).

Hooks shall not be used in such a manner as to place a side load or back load on the hook.

(See Figures 2a and 2b).

When using a device to close the throat opening of the hook, care shall be taken that the load is not carried by the closing device. (See Figures 3a and 3b).

Hands, fingers and body shall be kept from between hook and load.

The use of a hook with a latch does not preclude the inadvertent detachment of a slack sling or a load from the hook. Visual verification of proper hook engagement is required in all cases.

Chain sling WLL when choked with BK self-locking hooks equals 80% of sling identification tag WLL.

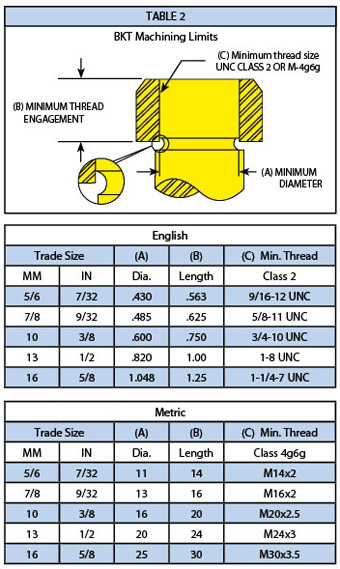

BKT self-locking hook shank machining limits are defined and are given in TABLE 2 and these limits are required for Work Load Limits given in TABLES 1A and 1B. Failure to comply can result in stripped threads and loss of load.

Hook shank threads shall end with a thread relief. Hook shank shall not be swaged to wire rope or rod. Hook shank shall not be drilled and internally threaded.

Never use a worn-out or damaged hook.

OSHA 1910.184(d) states, “Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use where service conditions warrant. Damaged or defective slings shall be immediately removed from service.”

|

Gunnebo Johnson Corp. and/or Lift-It® Manufacturing Co., Inc. cannot assume responsibility for:

(1) Machining quality, (2) Application or (3) Attachment to power source or load.

|

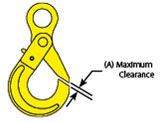

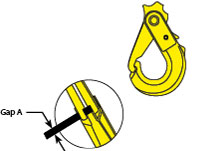

Hook latch shall properly close and lock.

Self-locking hooks with latch tip opening greater than the amount given in TABLE 3A and TABLE 3B shall be removed from service and shall not be returned to service unless properly repaired.

|

TABLE 3A

|

|

|

|

Trade Size

|

(A) Maximum Clearance

|

|

Material Handling

|

Personnel Handling

|

|

MM

|

IN

|

MM

|

IN

|

MM

|

IN

|

|

5/6

|

7/32

|

2.2

|

.09

|

1.5

|

.06

|

|

7/8

|

9/32

|

2.7

|

.11

|

1.9

|

.07

|

|

7

|

9/32

|

2.7

|

.11

|

1.9

|

.07

|

|

8

|

5/16

|

2.7

|

.11

|

1.9

|

.07

|

|

10

|

3/8

|

3.2

|

.13

|

2.2

|

.09

|

|

13

|

1/2

|

3.7

|

.15

|

2.6

|

.10

|

|

16

|

5/8

|

4.7

|

.19

|

3.2

|

.13

|

|

18/20

|

3/4

|

5.3

|

.21

|

3.6

|

.14

|

|

22

|

7/8

|

6.3

|

.25

|

4.2

|

.17

|

|

26

|

1

|

6.8

|

.27

|

4.6

|

.18

|

|

28

|

1-1/8

|

7.7

|

.30

|

5.1

|

.20

|

|

TABLE 3B

|

|

|

|

Trade Size

|

(A) Maximum Clearance

|

|

Material Handling

|

Personnel Handling

|

|

MM

|

IN

|

MM

|

IN

|

MM

|

IN

|

|

5/6

|

7/32

|

3.2

|

.13

|

2.2

|

.09

|

|

7/8

|

9/32

|

3.7

|

.15

|

2.7

|

.11

|

|

7

|

9/32

|

3.7

|

.15

|

2.7

|

.11

|

|

8

|

5/16

|

3.7

|

.15

|

2.7

|

.11

|

|

10

|

3/8

|

4.2

|

.17

|

3.2

|

.13

|

|

13

|

1/2

|

4.7

|

.19

|

3.7

|

.15

|

|

16

|

5/8

|

5.7

|

.23

|

4.7

|

.19

|

|

18/20

|

3/4

|

6.3

|

.25

|

5.3

|

.21

|

|

22

|

7/8

|

7.3

|

.29

|

6.3

|

.25

|

|

|

- NEVER use a hook without training

- ALWAYS inform yourself and ask your employer for hook safe use instructions.

- ALWAYS comply with applicable Federal and local regulations.

- ALWAYS know hook load.

- NEVER overload a hook.

- NEVER ride on hook or load.

- NEVER rig a hook improperly.

- NEVER use a worn-out or damaged hook.

- NEVER use a hook in extreme temperatures.

- NEVER use a hook in acidic conditions.

Always comply with applicable Federal and local regulations, which govern worksite activity.

Understand all governing laws and safety standards before using BK self-locking hooks. OSHA 1910.184 regulates sling safe operating practices, product identification, inspection requirements and use limitations. ASME B 30.9 “Sling” safety standard and B30.10 “Hooks” provides additional recommendations for chain sling and hook usage.

“If a particular standard is specifically applicable to a condition, practice, means, method, operation or process, it shall prevail over any different general standard.” OSHA 1910.5 (c) (1)

Contact OSHA at (800) 321-6742 or www.OSHA.gov and ASME at (800) 843-2763 or www.ASME.org for reference assistance.

Always know hook load to avoid hook failure.

OSHA 1910.184 (i)(3)(i) stipulates, “Fittings shall be of a minimum break strength equal to that of the sling.”

Work Load Limit (WLL) is the maximum Working Load to be applied to BK self-locking hooks for the specific application. WLL applies to in-line loading and does not include torsional, binding, shock or side load effects.

“The design factor for alloy steel chain slings shall be a minimum of 4.” ASME B30.9-1.4

“The design factor for wire rope slings shall be a minimum of 5” ASME B30.9-2.4

“The design factor for synthetic rope slings shall be a minimum of 5.” ASME B30.9-4.4

“The design factor for synthetic webbing slings shall be a minimum of 5.” ASME B30.9-5.4

“The design factor for roundslings shall be a minimum of 5.” ASME B30.9-6.4

Standard Gunnebo Lifting Work Load Limits are based on a 4/1 design factor. Lift dynamics, duty cycle and lift system type may require an increased design factor, hence a reduced WLL. Inattention to required design factor can result in hook overload. Contact Gunnebo Johnson Corp. Service Department for assistance at (800) 331-5460.

Never ride on hook or load. Avoid death or injury.

OSHA 1910.184(c)(9)-Sling use regulation stipulates: “All employees shall be kept clear of loads about to be lifted and of suspended loads.”

|

TABLE 1B

|

|

GR 100 ALLOY STEEL BK SELF-LOCKING HOOK

Work Load LimitS (Lbs.)*

|

|

TRADE SIZE

|

DESIGN FACTOR

|

|

MM

|

IN

|

4:1

|

5:1

|

6:1

|

9:1

|

|

5/6

|

7/32

|

2700

|

2160

|

1800

|

1200

|

|

7/8

|

9/32

|

5700

|

4560

|

3800

|

2530

|

|

10

|

3/8

|

8800

|

7040

|

5860

|

3900

|

|

13

|

1/2

|

15000

|

12000

|

10000

|

6660

|

|

16

|

5/8

|

22600

|

18080

|

15060

|

10040

|

|

18/20

|

3/4

|

35300

|

28240

|

23530

|

15680

|

|

22

|

7/8

|

42700

|

34160

|

28460

|

18970

|

|

*Work Load Limits are valid between temperatures of -40°F and 400°F.

|

Self-locking hooks shall be locked during use.

ASME B30.10-1.3 states, “When a hook is equipped with a latch, the latch should not be restrained from closing during use.”

Self-locking hooks shall not be rigged with more than two (2) sling legs in the hook saddle and sling leg angles shall not be greater than 45° from hook centerline.

(See Figure 1b)

Self-locking hooks shall be rigged with a masterlink or shackle when three (3) or more sling legs are used or sling leg angles exceed 45° from hook centerline.

(See Figure 1c)

Synthetic slings may require a Work Load Limit (WLL) reduction when used in self-locking hook eye or saddle. Contact the synthetic sling manufacturer for recommendations.

OSHA 1910-184 (e) (3) (i) stipulates, “In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of: (A) frequency of sling use; (B) severity of service conditions; (C) nature of lifts being made and (D) experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.”

OSHA 1910.184 (e) (3) (iii) states, “The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.”

OSHA 1910.184 (e) (7) (i) states, “Worn or damaged alloy steel chain slings or attachments shall not be used until repaired.”

Self-locking hooks with wear greater than 10 percent of the original dimension for any cross-section shall be removed from service.

Inspect self-locking hooks and threads with magnetic particle and/or dye penetrant at intervals no greater than once annually. Some disassembly may be required.

Self-locking hooks with corroded threads shall be removed from service and shall not be returned to service unless approved by a competent person.

Self-locking hooks that are broken, cracked, bent, stretched, twisted or welded on shall be removed from service and shall not be repaired.

Self-locking hooks that are nicked, gouged or lapped shall be removed from service and shall not be returned to service unless properly repaired.

Never use a hook in extreme temperatures.

Alloy steel BK self-locking hooks shall not be used in temperatures above 1000°F or cooled below -40°F.

Alloy steel self-locking hooks shall be permanently removed from service if heated above 1000°F.

Work Load Limits (WLL) given in TABLES 1A and 1B are valid between temperatures of -40° and 400°F.

WLL shall be reduced in accordance with TABLES 4A and 4B when heated between 400°F and 1000°F.

Permanent WLL reduction shall be made in accordance with TABLES 4A and 4B for self-locking hooks heated over temperatures indicated. Lifting equipment identification tag shall be replaced and the new tag shall have the reduced WLL.

Never use a hook in alkaline or acidic conditions.

Gunnebo alloy steel BK self-locking hooks shall not be used in alkaline or acidic conditions. Resulting metal embrittlement and accelerated corrosion can cause sudden failure. Hot dipped galvanizing and electro-zinc plating shall be done only by Gunnebo.

|

TABLE 4A Grade 80

|

|

Sling Component

Temperature

|

Percentage of TABLE 1A WLL

|

|

During Exposure

|

After Exposure

|

|

-40°F to 400°F

|

None

|

None

|

|

>400°F to 500°F

|

95%

|

None

|

|

>500°F to 600°F

|

90%

|

None

|

|

>600°F to 700°F

|

82%

|

None

|

|

>700°F to 800°F

|

75%

|

90%

|

|

>800°F TO 900°F

|

65%

|

75%

|

|

>900°F TO 1000°F

|

60%

|

70%

|

|

TABLE 4B Grade 100

|

|

Sling Component

Temperature

|

Percentage of TABLE 1B WLL

|

|

During Exposure

|

After Exposure

|

|

-40°F to 400°F

|

None

|

None

|

|

>400°F to 500°F

|

95%

|

95%

|

|

>500°F to 600°F

|

90%

|

90%

|

|

>600°F to 700°F

|

82%

|

85%

|

|

>700°F to 800°F

|

75%

|

80%

|

|

>800°F TO 900°F

|

65%

|

75%

|

|

>900°F TO 1000°F

|

60%

|

70%

|

|