Renfroe Plate Clamps Definitions and Warnings

Renfroe Plate Clamps Definitions and Warnings

![]() The capacity of all horizontal clamps is based on a sling angle of sixty degrees. Sling angles less than sixty degrees (60°) increase the load exerted on the clamps. Sling angles greater than 60° reduce gripping force, DO NOT EXCEED 60°.

The capacity of all horizontal clamps is based on a sling angle of sixty degrees. Sling angles less than sixty degrees (60°) increase the load exerted on the clamps. Sling angles greater than 60° reduce gripping force, DO NOT EXCEED 60°.

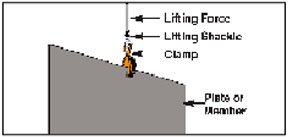

VERTICAL LIFT: The lifting of a single plate or member

in which the lifting force exerted by the rigging is directly above and in line with the lifting shackle as shown in the illustration below.

VERTICAL TURN/LIFT CLAMP: A Vertical Turn/Lift Clamp is a vertical lifting clamp specifically intended to turn a single plate or member through a 90° arc and back to vertical through the same 90° arc or from horizontal to vertical to horizontal through a 180° arc. Refer to specific Turn/Lift Clamps for further detail.

During the turning operation the edge of the plate opposite the edge to which the clamp is attached should always be in contact with a supporting surface such as a floor and the load on the clamp should not exceed one half of the clamp’s rated capacity. Refer to illustrations shown below.

HORIZONTAL LIFT: Clamps (used in pairs or multiples) are attached to the side edges of a plate or bundle of plates positioned horizontally to floor level. The rigging attached to clamps is generally multi-legged slings with the connecting point of the slings being approximately centered between the distance separating the clamps. Refer to illustrations shown below.

![]() Never use clamps for lifting a plate when the plate thickness is less than or greater than the minimum and maximum thickness indicated on the clamp.

Never use clamps for lifting a plate when the plate thickness is less than or greater than the minimum and maximum thickness indicated on the clamp.

JAW OPENING: The minimum and maximum thickness of a member of a clamp, referred to as JAW OPENING is capable of handling.

![]() Never use a clamp on a member whose thickness is less than or greater than range of jaw opening stenciled on the clamp.

Never use a clamp on a member whose thickness is less than or greater than range of jaw opening stenciled on the clamp.

OPERATING TEMPERATURES: Unless specified for the individual model, the approved operating temperature of Renfroe clamps is from 0°F/(-18°C) to a maximum of 200°F/(93°C). Minimum and maximum temperatures apply to both ambient and contact temperatures.

![]() Secure written authorization from Renfroe before using clamps in temperatures outside the acceptable range.

Secure written authorization from Renfroe before using clamps in temperatures outside the acceptable range.

HOT LIFTS: Model R and S clamps are available with

modifications that make them capable for lifts where the

contact temperature exceeds 200°F/(93°C). The exact

application and temperature of the plates to be

handled are critical in selecting the proper plate clamp.

![]() Secure written instructions from Renfroe for all hot lift applications.

Secure written instructions from Renfroe for all hot lift applications.

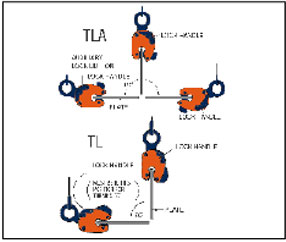

LOCKING CLAMPS: Locking Clamps are divided into the following categories. With the exception of the “Locking Wedge” and “Locking Screw” type, the purpose of the locks is to facilitate the attaching and removing of the clamp from the member being handled.

LOCK CLOSED: An over-center spring loaded mechanism in which the spring exerts a force on the gripping cam when the lock handle is moved to the “Lock Closed” position. When the handle is moved to unlocked position the force exerted by the spring is relaxed and the gripping cam may be retracted by pushing the lifting shackle into the body of clamp. Refer to the specific models of “Lock Closed” clamps for additional details. Typical “Lock Closed” clamps are Models: DG, FR, M and HRS.

STEEL PLATES: Unless otherwise specified, lifting clamps are manufactured to handle hot-rolled steel plates with a Brinell Hardness not exceeding 300.

Do not lift plates with coatings or mill scale that prevents clamp gripping surfaces from making positive contact with the base metal.

For applications not covered by the above information, secure written recommendations from Renfroe.

FINISHED AND POLISHED STEEL PLATES: Steel plates in this category having other than hot-rolled surfaces such as stainless steel, etc., are generally handled using non-marring clamps incorporating smooth gripping surfaces.

For applications using clamps with serrated gripping surfaces on finished or polished plates, secure written recommendations from Renfroe.

STRUCTURAL MEMBERS – FABRICATED SECTIONS: Unless otherwise specified, clamps described as capable of handling structural members and fabricated sections are limited to hot-rolled steel with a Brinell Hardness not exceeding 300.

For applications not covered by the above information, you must in all cases secure written recommendations from Renfroe.

RATED CAPACITY:

ALL RENFROE CLAMPS ARE RATED INDIVIDUALLY.

The rated capacity of Renfroe products is based on the product being in “new or as new” condition and represents the maximum load products are to be subjected to when utilized in the manner described in this manual. Wear, misuse, abuse and other factors relating to usage may reduce the rated capacity. Shock loading must be avoided and all factors must be taken into consideration when selecting a Renfroe product for a given application.

PLATE THICKNESS: The minimum and maximum plate thickness a clamp specified for handling plates is capable of lifting.

LOCK OPEN ONLY: Normally used on “Hot Lift” clamps and consists of a manually operated “Lock Stop Pin” that is inserted when gripping cam of clamp is retracted and removed when the clamp is positioned on the plate. Tag lines may allow the operator to remove pin from a greater distance from clamp. Refer to the specific models of “Lock Open Only” clamps for additional details. Typical “Lock Open Only” clamp is Model RO.

LOCK OPEN-LOCK CLOSED: An over-center spring loaded mechanism in which the spring exerts a force on the gripping cam when the lock handle is moved to the “Lock Closed” position. When the handle is moved to the “Lock Open” position, the gripping cam is maintained in the retracted position for ease in installing the clamp on a plate or member. Model FRD clamps contain individual “Lock Open” and “Lock Closed” mechanisms that must be operated separately. Refer to the specific models of the “Lock Open-Lock Closed” clamps for additional details. Typical “Lock Open-Lock Closed” clamps are Models: FRD, R, S, SD, SEA, SX, TL, TLA and the J-Series.

LOCKING WEDGE: A fluted steel wedge that is driven in place with a hammer. The wedge body is positioned in the clamp body slot with the fluted edges contacting the member being attached to the clamp. Refer to the specific models of “Locking Wedge” clamps for additional details. Typical “Locking Wedge” clamps are Models: A1, B1, B2 and PB.

LOCKING SCREW: “Locking Screw” clamps depend on the manual adjustment of a screw to hold the gripping surface in place for lifting and clamp removal. Refer to the specific models of “Locking Screw” clamps for additional details. Typical “Locking Screw” clamps are Models: AC, ACP, BC, NM, PC, SCP,

SCPA and RSC.

NON-LOCKING: “Non-Locking” clamps have no mechanisms to aid in attaching or removing clamp from member being lifted. It is necessary to have the position of clamp maintained on the member being lifted until a properly applied force is exerted to the lifting shackle. Refer to the specific models of “Non-Locking” clamps for additional details. Typical “Non Locking” clamps are Models: AST, ASTL, BD, HR, HDR, HRS and WHSR.

![]() A pointing out and notice of danger. The purpose of a “warning” is to apprise operators and all other affected persons of the existence of danger of which they should be, but may not be aware of; and to enable the operators to protect themselves and others, where applicable, against such danger. An attempt is made herein to warn against reasonable and reasonably foreseeable danger in the proper use and possible misuse of Renfroe products depicted in our catalog.

A pointing out and notice of danger. The purpose of a “warning” is to apprise operators and all other affected persons of the existence of danger of which they should be, but may not be aware of; and to enable the operators to protect themselves and others, where applicable, against such danger. An attempt is made herein to warn against reasonable and reasonably foreseeable danger in the proper use and possible misuse of Renfroe products depicted in our catalog.