|

What follows are some useful tips to help riggers do their jobs more efficiently and safely. Prevailing work rules and government regulations place full responsibility for proper performance upon the rigger, so it is his/her duty to be familiar with the condition and capability of all tools and equipment used, as well as techniques employed. One basic rule always applies: Always know, never guess.

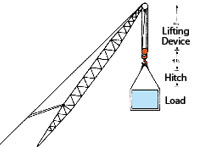

Each lift may be divided into three parts, providing a convenient plan for successful rigging:

1. The Lifting Device: Know its capability, limitations

and condition. When was the lifting device last inspected? If in doubt about capacity, check the placard or other appropriate records.

2. The Hitch: Here is where the rigger can exercise ingenuity, but it is also the easiest place to make a mistake.

3. The Load: The weight must be known. You must also protect the load from possible damage by the slings and protect the slings from damage by the load.

Is the lifting device adequate?

Check the placard on the crane or hoist, and then answer three questions:

1. Is capacity adequate for this lift?

2. Will it lift high enough?

3. Is the horizontal reach adequate?

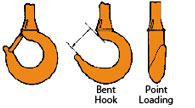

Check hooks & reeving

1. Are sheaves properly rigged? If multi-part reeving,

will it support the load?

2. Is the hook the right size so sling eyes won’t be

distorted when placed over the hook?

3. Check for cracks in bowl of the hook and for

evidence of point loading or bending.

|

|

Before you select a sling for a specific lift, determine the most effective hitch to do the job, protect the load and protect the sling.

The type of hitch you select may determine the type of sling that will best do the job, as well as the length of sling that will be needed. Lifting height, overhead clearance and hook travel will affect the hitch selection and sling length.

Select slings that will best support the load while providing adequate rated capacity. The proper choice will provide:

1. Lifting capacity needed.

2. Proper D/d Ratio.

3. Handling characteristics needed for rigging.

4. Minimal damage to the sling.

5. Minimal damage to the load.

|

|

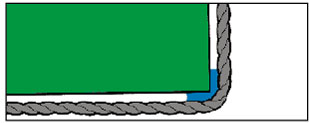

Protect slings during the lift with blocking or padding that is adequate to prevent sling or load damage.

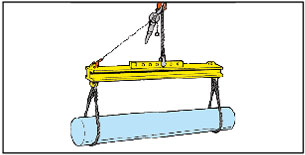

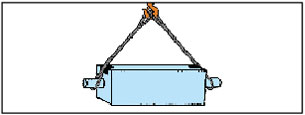

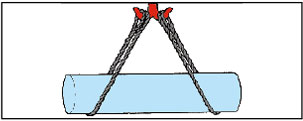

Use a spreader bar between sling legs to prevent excessive side pressure on the load from sling contact during the lift. One sling in is depicted for illustration purposes only.

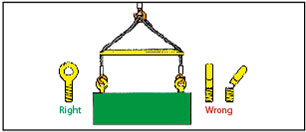

When attaching slings to eye bolts, always pull in line with the bolt axis. A side pull may break the eye bolts. Eye bolts without shoulders cannot be used for angular lifting.

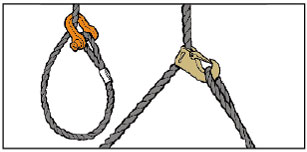

Use a shackle in sling eyes during a choke to protect sling body against excessive distortion. Always put shackle pin through sling eye, rather than against the sling body. If the shackle is installed incorrectly the sliding movement of the sling body could rotate and disengage the shackle pin.

A sliding hook choker is superior to a shackle or unprotected eye, since it provides a greater bending radius for the sling body.

You can improve the angle of a choke with blocking between the hitch and the load. The angle of choke increases, improving sling efficiency. Please Note: One sling is depicted for illustration purposes only.

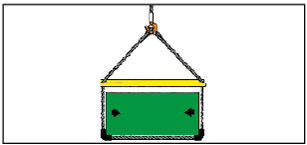

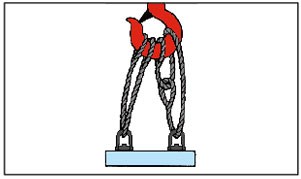

An equalizing bar with two slings rigged in a basket hitch reduces the tendency of slings to slide and keeps the load level. By adjusting the lifting point and using a Lever Hoist to support the heavy end, the load can be kept level during the lift.

When rigging two or more slings as a bridle, select identical sling constructions and lengths with identical previous loading experience. Sling stretch must be the same for paired slings to avoid overloading individual legs and to provide load control.

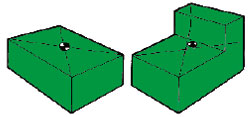

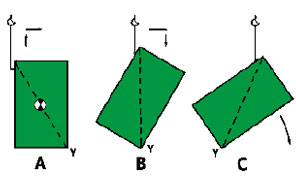

The Center of Gravity for rectangular objects with homogeneous characteristics will usually be below the junction of lines drawn diagonally from opposite corners. When a rectangular object has weight concentrated at one end, the Center of Gravity will be situated toward that end – away from the intersection of diagonal lines. To avoid an unbalanced lift, the lifting hook must be rigged directly above the Center of Gravity. The Center of Gravity for rectangular objects with homogeneous characteristics will usually be below the junction of lines drawn diagonally from opposite corners. When a rectangular object has weight concentrated at one end, the Center of Gravity will be situated toward that end – away from the intersection of diagonal lines. To avoid an unbalanced lift, the lifting hook must be rigged directly above the Center of Gravity.

To turn or reposition a load, either one or two lifting devices may be employed. Always use a choker hitch. Never attempt to turn a load with a basket, since the load will slide against the sling body, resulting in damage to both the sling and load.

|

|

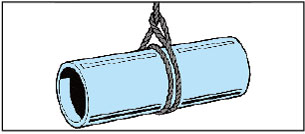

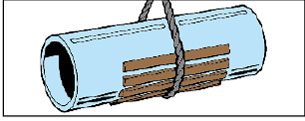

When lifting a bundled load, a choke is more effective than a basket hitch to provide control and prevent slipping of the load in the sling. Odd numbers of rounded objects will nestle as even numbers tend to slide out. If practical use more than one sling and employ a double wrap choke hitch. Please Note: One sling is depicted for illustration

purposes only.

Use a double wrap choke hitch around the load for 360° load contact, to prevent load slippage. Please Note: One sling is depicted for illustration

purposes only.

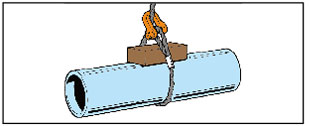

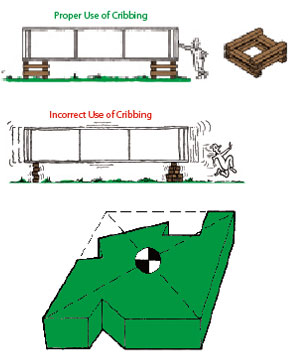

Use blocking or padding to protect hollow vessels, loose bundles and fragile items from scuffing and bending. Remember, blocking becomes part of the load and must be added to the total load weight. Please Note: One sling is depicted for illustration purposes only.

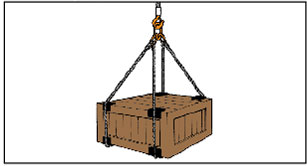

When lifting crates or wooden boxes in a basket hitch, be sure the load can withstand side pressure as sling tension is applied. Use spreader bars and sling protection to prevent damage.

Two slings rigged in a basket hitch provide better balance for loads. Be sure that slings cannot slide along the load when the lift is made and use extreme caution.

Hand-spliced slings should not be used in lifts where slings may rotate and cause the wire rope to unlay. Hand-spliced slings should not be used in lifts where slings may rotate and cause the wire rope to unlay.

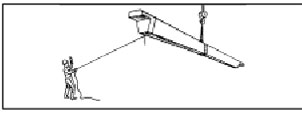

Use taglines to prevent load rotation. The further from the load’s center of gravity the tag line is placed, the greater degree of control with less effort is realized.

To locate the approximate Center of Gravity of an irregularly shaped article, visualize it enclosed by a rectangle. Where diagonals from opposite corners intersect will usually indicate a location for a lift point near the Center of Gravity.

|

|

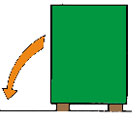

To turn a load with one hook, attach the sling directly to the load ABOVE the Center of Gravity. The lifting hook must be able to move, or travel, in the direction of the turn to prevent sliding of the load’s pivot edge as the load leaves the ground. It may be necessary to lift the load again to reposition it after the turn is completed. Irregular shapes sometimes will require blocking for support during and after the turn.

Lifting unbalanced loads when exact length slings are not available can be accomplished by rigging an adjustable hitch on the heavy end. Sling length can be adjusted before weight is applied, but once sling loading occurs, the hitch is locked in position for the lift.

|

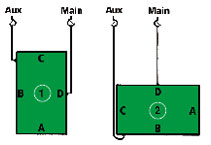

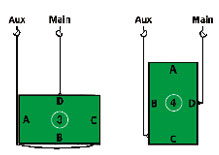

Two-hook turning is employed when it is desired to turn the load in the air. Main and auxiliary hoists of a crane can be used, if permitted or two cranes can be used.

To turn from side (A) to (B) in 1 & 2 above, attach to side (B) above the Center of Gravity and to side (D) at the Center of Gravity, then lift both hoists equally until load is suspended. Lower until turn is completed.

To turn from side (B) to (C) in 3 & 4 above, lift balanced load at (D) directly above the Center of Gravity; then auxiliary at (B) to desired position. Lower both hooks simultaneously until side (C) is in desired position.

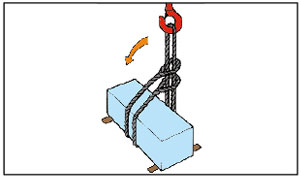

Turning with a double choker gives good control. To rig, place both eyes on top of load, pointing opposite the direction of turn. Body of sling is then passed under load, through both eyes and over lifting hook. Blocking should be used under the load to protect sling and facilitate removal.

|

|