|

Any sling can be damaged, abraded or cut as tension and compression develops between the sling, connection points and/or the load. Slings must ALWAYS be protected from cutting and damage by edges, corners, protrusions and abrasive surfaces in contact with the sling with materials of sufficient strength, thickness and construction to prevent damage and catastrophic sling failure.

The edge of the load does not have to be “razor” sharp to create the conditions for sling failure. A combination of non-positive sling to load contact (sling slipping across the load) and inadequate sling protection materials may result in sling protection damage and failure. Sling protection may not prevent cutting or other forms of sling damage, for this reason personnel should never be under or on the load, while the load is lifted or suspended.

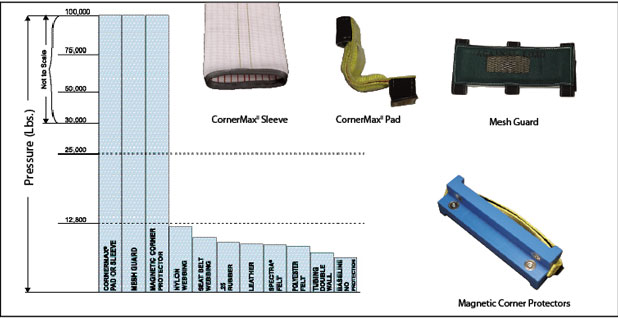

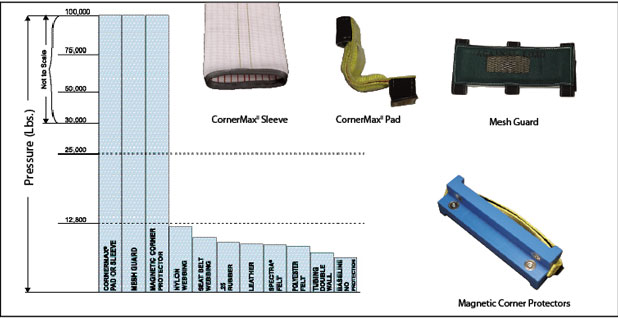

“Cut proof” sling protection does not exist. Materials must be evaluated and selected based upon the application and type of exposure. Some materials are suitable for abrasion resistance, but offer virtually no protection against the effects of cutting. You should always operate within the specified sling and protection device limits. Twin-Path® Extra High Performance Slings can develop 25,000 Lbs. per Inch Work Load Limits. Web slings can develop 12,800 Lbs. per Inch Work Load Limits.

Certain materials used in sling protection have been evaluated for cut resistance. Magnetic Corner Protectors, CornerMax® Pads, CornerMax® Sleeves and Meshguard® sling protectors are rated for cut resistance.

Regardless of the particular method chosen, the goal is to ensure that the sling maintains its ability to securely lift the load while avoiding contact with damaging or abrasive surfaces under tension. A qualified person must carefully consider the appropriate means to accomplish this goal by selecting sling protection appropriate for the types of exposure damage. The protection used should not be makeshift (i.e., selecting and using cardboard, work gloves or other such items that were not designed to serve as protection devices).

Sling protection must be installed and evaluated for suitability by raising the load slightly and then lowering the load for an inspection of the sling and the protection devices. Several “test” lifts, inspections and evaluations may be necessary to determine the proper form of protection for a successful lift. Damaged or misused sling protection can result in sling failure. Inspect the sling protection before each use and remove if damaged. Be sure sling protection is the correct type and size to protect the sling. The length of the sleeve or protection material(s) must not interfere with the sling closing to the full gripping position on the load. Sling protection may not prevent cutting or other forms of damage. To avoid severe personal injury or death, personnel should be kept away from the load and never be under or near the load, while it is being lifted or suspended. Personnel should never be next to rigging that is under tension. Sling protection must be installed and evaluated for suitability by raising the load slightly and then lowering the load for an inspection of the sling and the protection devices. Several “test” lifts, inspections and evaluations may be necessary to determine the proper form of protection for a successful lift. Damaged or misused sling protection can result in sling failure. Inspect the sling protection before each use and remove if damaged. Be sure sling protection is the correct type and size to protect the sling. The length of the sleeve or protection material(s) must not interfere with the sling closing to the full gripping position on the load. Sling protection may not prevent cutting or other forms of damage. To avoid severe personal injury or death, personnel should be kept away from the load and never be under or near the load, while it is being lifted or suspended. Personnel should never be next to rigging that is under tension.

|

SLEEVES

Sleeves cover both sides of the sling and can be moved to a specific location. Sleeves can also be re-positioned for quick and easy inspection of the sling. Available in six different materials:

Bulked Nylon, Nylon, Leather, Neoprene, CornerMax® and Felt. Available in sewn edge, tubular and quick-sleeve constructions.

|

|

|

EYE WRAP

Eye Wrap at the bearing point is standard eye protection offered by Lift-It®. Sling eyes are wrapped with Bulked Nylon. Full length Eye Wrap is also available.

EYE BUFFER

If specified, Sling Eyes can be lined with Eye Buffers at the bearing point. The eye buffer can also be full length.

EYE SLEEVE

When additional protection is needed, consider Eye Sleeves. Hook and loop tape makes installation effortless and removal is quick and easy for inspection.

Please specify:

- Eye width and thickness

- Sleeve material

- Sleeve length

|

|

WEAR PADS

Wear pads are sewn to the sling for protection at specific wear areas. Wear Pads can be sewn at any location, in single or multiple layers and can be attached to one or both sides of the sling. Leather Wear Pads in excess of 5 feet are not recommended.

|

|

|

|

EDGE WRAP

Bulked Nylon or leather is sewn around the edge of the sling. Edge Wrap may be necessary in applications where abrasion damage occurs. Consider using Polyester Max Edge™ webbing.

|

|

|

|

BODY WRAP

Body Wrap is similar to the sleeve, but is sewn to a specific location. Body Wrap covers the webbing surface and the edges.

|

|

|

|