You have no items in your shopping cart.

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

-

Products

- Back

- Recovery Products

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

-

Round Slings

- Back

- Endless Round Slings

- Twin-Path Slings

- Rope Slings

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Material Handling

-

Stahlwille

- Back

- Torque Wrenches

- Tool Bags & Buckets

- Tie Downs

-

Hoists

- Misc.

- Training Programs

- Plate Clamps

-

Blocks

- Back

- Rope Blocks

-

Rope-Cordage

- Nets

- Safety Resources

- Helicopter Rigging

- Featured Products

-

Products

- Back

- Recovery Products

-

Sling Protection

- Back

- CornerMax® Sleeves

- CornerMax® Velcro Pads

- CornerMax® Pads

- Magnetic Corner Protectors

- Quick Sleeves - Felt

- Sewn Sleeves - Felt

- Quick Sleeve - Nylon

- Sewn Sleeve - Nylon

- Quick Sleeve - Web

- Sewn Sleeve - Web

- Sewn Chap Sleeves - Felt

- Quick Chap Sleeves - Cordura®

- Quick Tubular Sleeves - Felt

- Quick Tubular Sleeves - Nylon

- Quick Tubular Sleeves - Web

- Chafe Gear

- Shackle Pin Protector Pads

- Wire Rope Saddle Protectors

-

Lifting Slings

- Back

-

Web Slings

- Back

- Eye & Eye Slings

- Polyester Max Edge™ Eye & Eye Slings

- Endless Sling

- Polyester Max Edge™ Endless Slings

- Basket Hardware Slings

- Choker Hardware Slings

- Reversed Eye Slings

- Wide Body Cargo Slings

- Attached Eye Cargo Slings

- Single Leg - Eye & Eye Sling Bridles (SLB)

- Double Leg - Eye & Eye Sling Bridles (MLB2)

- Triple Leg - Eye & Eye Sling Bridles (MLB3)

- Quad Leg - Eye & Eye Sling Bridle Assembly (MLB4)

-

Round Slings

- Back

- Endless Round Slings

- Twin-Path Slings

- Rope Slings

- Special Purpose Slings

- Bridle Assemblies

- Cargo Slings

- Wire Rope Slings

- Chain Slings

- Utility Slings

- Wind Industry

- Container Lifting Assemblies

- Marine Slings

- Rail Industry Slings

- Mining Slings

-

Rigging Hardware

- Back

-

Shackles

- Back

- Van Beest® G-4161 Screw Pin Anchor Shackles

- Van Beest® G-4163 Bolt, Nut & Cotter Anchor Shackles

- Van Beest® P-6033 Wide Body Sling Shackles

- Van Beest® G-5263 Bolt, Nut & Cotter Alloy Anchor Super Strong Shackles

- Van Beest® G-4263 Screw Pin Wide Mouth Shackles with Bolt, Nut and Cotter

- Crosby® G-209 Screw Pin Anchor Shackle

- Van Beest® P-4161T Theatre Shackles

- Fittings & Connectors

-

Hoist Rings

- Back

- Actek® Swivel Hoist Ring

- Actek® Metric Swivel Hoist Ring

- Actek® Stainless Swivel Hoist Ring

- Actek® Metric Stainless Swivel Hoist Ring

- Actek® Ultra Lifting Ring

- Actek® Metric Ultra Lifting Ring

- Actek® Sideload Hoist Ring

- Actek® Metric Sideload Hoist Ring

- Actek® Forged Swivel Hoist Ring

- Actek® Metric Forged Swivel Hoist Ring

- Hooks

- Eye Bolts

- Turnbuckles

- Masterlinks

- Material Handling

-

Stahlwille

- Back

- Torque Wrenches

- Tool Bags & Buckets

- Tie Downs

-

Hoists

- Misc.

- Training Programs

- Plate Clamps

-

Blocks

- Back

- Rope Blocks

-

Rope-Cordage

- Nets

- Safety Resources

- Helicopter Rigging

- Featured Products

- Shop

- Quality

- Services

- Our Expertise

- Product Warning

- Videos

- Blog

- Contact Us

- 909-469-2251

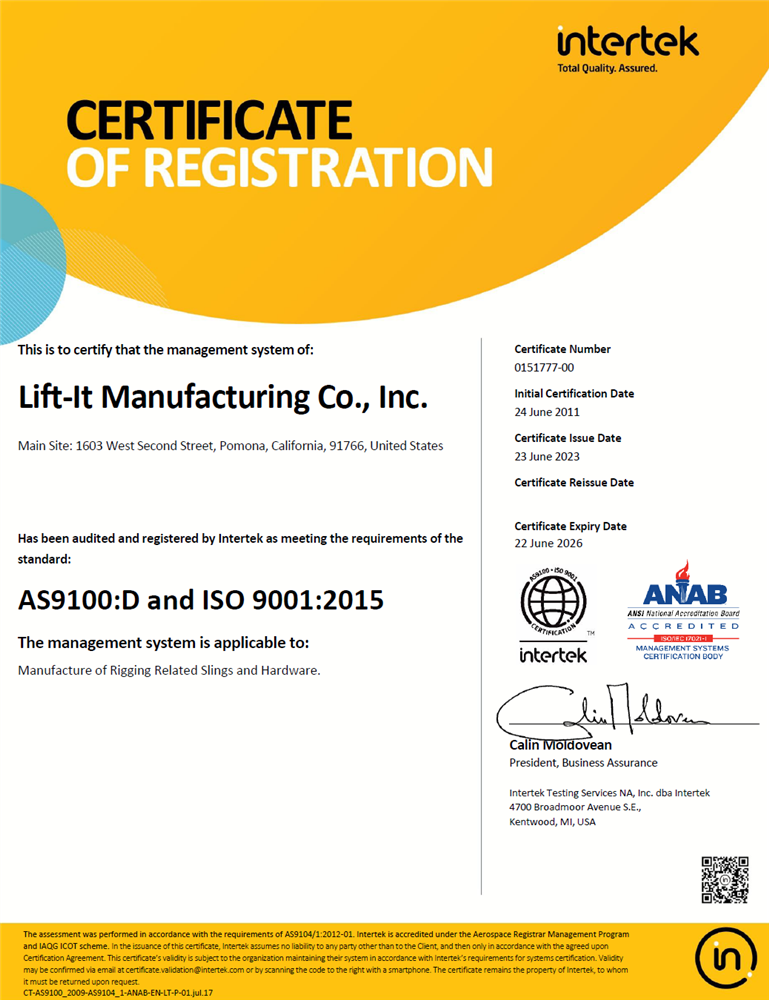

AS9100, ISO9001 Certificate of Registration

Since our first day of operation, we had a stringent, quality management system. Only the finest materials are used in every product we manufacture. Only qualified vendors, with products liability insurance, supply components which meet or exceed our discriminating standards.

Samples from every lot of thread and load carrying yarn are pulled to destruction, prior to use to ensure that quality expectations are realized.

All products are initialed by the fabrication specialist and stamped by the quality inspector. Our material traceability system begins with the assignment of a unique “container” number for materials and components. The container number is recorded on the fabrication order. The key to our traceability system is the unique invoice and associated serial number assigned to each product. Serial numbers are recorded on the product tag for the purposes of identifying input materials and quality standards compliance.

Stringent material and production standards, written quality control procedures and inspection records demonstrate the ultimate in corporate responsibility. We are committed to quality that is generally not seen, but makes a significant difference between the best and all the rest.

The decision to take the step from an internally developed quality system to one that would be “world class” was an easy one. The many steps necessary to obtain and maintain registration require much dedication, time, resources and money. After completing the process, we asked ourselves, why would anyone want to work with a manufacturer that is not ISO registered?

ISO 9001 is a generic product standard that provides quality assurance requirements and quality management guidance. Essentially, ISO 9001:2015 requires a company to document what it does and do what it has documented.

To establish an ISO program a company works with a consultant to provide a blueprint for the many, necessary documents that must be created. Everything that a corporation does is written into administrative, quality and implementation procedures. When this is completed and all parties are trained to fulfill their duties as specified by the procedures, the company is audited for compliance by an independent registrar. If the audit is successfully accomplished the company is then registered and issued a certificate indicating official ISO Quality Registration. Audits of the program occur annually to maintain a current certificate of registration.

In January 2002, Michael Gelskey, Jr. was appointed the Lift-It® Quality Manager and began working with Steven Guydos, SG Consulting. In November 2002, the registration audit was performed by Gregory A. Patrissi of SAI Global, Inc. Mr. Patrissi verified that Lift-It® Mfg. had in place a well maintained quality program. He also commented that after auditing Lift-It®, it would become the benchmark by which other rigging shops would be evaluated.

Lift-It® Manufacturing is proud to join the growing number of elite companies that meet the quality standards established by the International Standards Organization. SAI Global registered our initial compliance in 2003 and every subsequent year to the present ISO 9001:2015 standard.

We now have the distinction of our upgraded registration to the prestigious AS9100D, Quality Management Systems-Regulations for Aviation, Space and Defense Organizations. AS9100 defines additional requirements within an aerospace quality management system when operating to an ISO9001 Quality System and is traceable to the Code of Federal Regulations (CFR), Title 14, Part 21.

Mike Gelskey, Jr. commented, “We know that the implementation of this program will make us an even better manufacturer and supplier for our customers. Our documented quality management systems demonstrate our commitment to continuous process improvements and complete customer satisfaction”.