|

Adjustable Rope Sling users shall be trained in the selection, inspection, cautions to personnel, environmental considerations and rigging practices. Be sure to read and understand information that accompanies the sling and is contained in this publication. Refer to information on mechanical and environmental considerations. Use by untrained persons may result in INJURY or DEATH.

Adjustable Rope Slings must be protected from damage by materials of sufficient strength, thickness and construction. Refer to Sling Info Sheet for sling protection information.

Inspect prior to use for frayed strands and broken yarns. A pulled strand can snag during use. Do not use Adjustable Rope Slings that appear to be damaged. If there is any doubt, do not use the sling; remove it from service for evaluation. Refer to Web Sling Inspection for information on Sling Inspection Systems. Be sure to employ all three levels of inspection: Initial, Frequent and Periodic. No visual inspection can accurately determine the residual strength of the sling

.

Both outer and inner rope fibers contribute to the strength of Adjustable Rope Slings. When either is worn, Adjustable Rope Slings are weakened. Heavy use will cause the rope to be compacted or hard. This is an indication that rope tensile strength has been reduced.

UV degradation is indicated by discoloration and the presence of splinters and slivers on the rope surface.

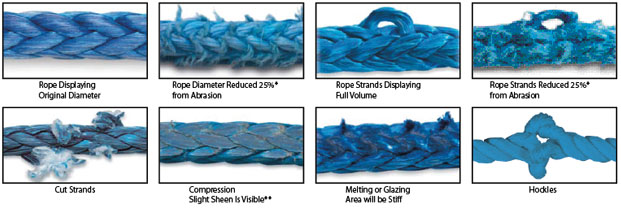

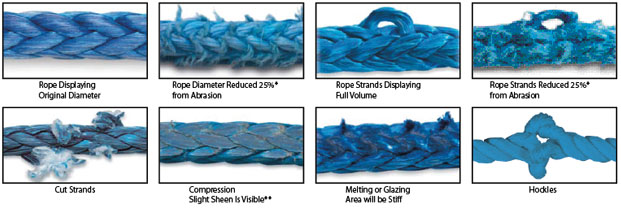

Sling Damage Examples

If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only. If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only.

* 10% is cause for removal from service **Don’t confuse compression with heat damage.

Removal From Service Criteria

Synthetic rope slings shall be removed from service if conditions such as the following are present:

- Missing or illegible sling identification. Identification content for rope sling tags is identical to web sling tag requirements.

- Cuts, gouges, areas of extensive fiber breakage along the length and abraded areas on the rope.

- Damage that is estimated to have reduced the effective diameter of the rope by more than 10%.

- Uniform fiber breakage along the major part of the length of the rope in the sling such that the entire rope appears covered with fuzz or whiskers.

- Inside the rope, fiber breakage, fused or melted fiber (observed by prying or twisting to open the strands) involving damage estimated at 10% of the fiber in any strand or the rope as a whole.

- Discoloration, brittle fibers and hard of stiff areas that may indicate chemical damage, ultraviolet light damage or heat damage.

- Dirt and grime in the interior of the rope structure that is deemed excessive.

- Foreign matter that has permeated the rope and makes it difficult to handle and may attract and hold grit.

- Kinks and distortion in the rope structure, particularly if caused by forcibly pulling on loops (known as hockles).

- Melted, hard or charred areas that affect more than 10% of the diameter of the rope or affect several adjacent strands along the length that affect more than 10% of strand diameters.

- Poor condition of thimbles or other components manifested by corrosion, cracks, distortion, sharp edges or localized wear.

- For hooks, removal criteria as stated in ASME B30.10.

- For rigging hardware, removal criteria as stated in ASME B30.26.

- Other visible damage that causes doubt as to the strength of the sling.

|