|

Slings exposed to abrasion and cutting are the single greatest source of accidents, injuries, death and destruction. Synthetic slings are not the absolute solution for all rigging applications. The proper approach should always be to use the “right” sling for the job to minimize risk and exposure.

All slings have limitations. Synthetic slings are susceptible to heat damage and damage from cutting and abrasion. One may improperly rationalize and conclude that chain, wire rope and/or wire mesh slings should be used in all harsh situations, which preclude the use of synthetics. Chain, wire rope and wire mesh slings are not totally “bullet” proof in all applications and can also be damaged.

ASME B30.9-2006, Section, 9.X.10.4(d), Rigging Practices, Chapters 1, 2 and 3 stated that Chain, Wire Rope and Wire Mesh slings should be padded with adequate materials to protect the sling. The sling protection language in the ASME Sling Safety Standard-Rigging Practice section is similiar in Chapters 4, 5 and 6 for synthetic rope, web and roundslings, except, should (a recommendation to be considered in Chapters 1, 2, and 3), was changed to shall, a mandatory rule of the standard for all synthetic slings. The ASME B30.9-2010 Sling Safety Standard requires that all synthetic slings shall be protected from damage.

“Sharp” was removed from the ASME B30.9-2006 Sling Safety Standard and had previously been removed from the Web Sling and Tie Down Association- Recommended Standard Specification for Synthetic Web Slings (WSTDA-WS-1-2004). The ASME B30.9 subcommittee and the WSTDA-Web Sling committee removed sharp from their publications because the edge need not be “razor” sharp to damage any type of sling. Compression and tension combined with a “moderate” edge and non-positive sling to load engagement, i.e., the sling skipping across the load edge, can result in sling damage and failure. It is important that responsible parties protect all slings from damaging load edges and surfaces with protection materials sufficient for the application and rig to properly control the load.

Another common misconception is sling protection devices will perform equally well when subjected to abrasion and/or cutting. It is important to realize that abrasion protection materials, designs and technology work differently from those methods taken to provide protection from cutting.

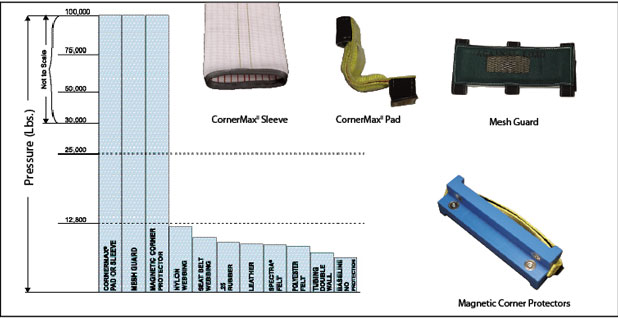

Web slings can have a 12,800 pound per inch, basket Work Load. Twin-Path® Extra, High Performance Fiber Slings can have a 25,000 pound per inch, basket Work Load. Testing conducted by Slingmax®, Unirope® and Lift-It® evaluated various sling protection materials and constructions. The results are featured on page 44. Four protection devices provided a sling protection “performance design factor” above the maximum 25,000 pound requirement: CornerMax® Pads, CornerMax® Sleeves, Mesh Guard® and Magnetic Corner Protectors.

I believe the initial steps of developing performance ratings for sling protection devices by visionaries: Dennis St. Germain, Gary O’Rourke, Knut Buschmann and the author will profoundly influence the direction of the sling and rigging industry. The Web Sling and Tie Down Association, has completed testing to determine the effects of various sized edge radii on web and roundsling strength. The results for roundslings are included in WSTDA-RS-1(2010) Recommended Standard Specification for Roundslings. The results for web slings are being evaluated by the Web and Testing committees of the WSTDA. The aforementioned radii tests and test protocol under consideration by the WSTDA may provide the basis for establishing protection ratings for various forms of engineered protection devices.

The sling user, inspector, loss control, safety and qualified person(s) must continue to be responsible and be involved in the selection, evaluation and proper application of protection devices. There is no form of protection that is cut proof; poor load control can render the best protection impotent.

We encourage all sling users to act responsibly and to evaluate sling protection devices and slings in a non-consequence set of circumstances. Test lifts can easily be made at minimum heights to determine sling protection adequacy. Slings and protection must be removed, inspected and evaluated after each test lift. Several “test” lifts may be necessary to determine the best sling, method of rigging for load control and sling protection devices to ensure success.

Remember, Successful Rigging = Successful Living.

|

| Web Sling Protection |

|

Any sling can be damaged, abraded or cut as tension and compression develops between the sling, connection points and/or the load. Slings must ALWAYS be protected from cutting and damage by edges, corners, protrusions and abrasive surfaces in contact with the sling with materials of sufficient strength, thickness and construction to prevent damage and catastrophic sling failure.

The edge of the load does not have to be “razor” sharp to create the conditions for sling failure. A combination of non-positive sling to load contact (sling slipping across the load) and inadequate sling protection materials may result in sling protection damage and failure. Sling protection may not prevent cutting or other forms of sling damage, for this reason personnel should never be under or on the load, while the load is lifted or suspended.

“Cut proof” sling protection does not exist. Materials must be evaluated and selected based upon the application and type of exposure. Some materials are suitable for abrasion resistance, but offer virtually no protection against the effects of cutting. You should always operate within the specified sling and protection device limits. Twin-Path® Extra High Performance Slings can develop 25,000 Lbs. per Inch Work Load Limits. Web slings can develop 12,800 Lbs. per Inch Work Load Limits.

Certain materials used in sling protection have been evaluated for cut resistance. Magnetic Corner Protectors, CornerMax® Pads, CornerMax® Sleeves and Meshguard® sling protectors are rated for cut resistance.

Regardless of the particular method chosen, the goal is to ensure that the sling maintains its ability to securely lift the load while avoiding contact with damaging or abrasive surfaces under tension. A qualified person must carefully consider the appropriate means to accomplish this goal by selecting sling protection appropriate for the types of exposure damage. The protection used should not be makeshift (i.e., selecting and using cardboard, work gloves or other such items that were not designed to serve as protection devices).

Sling protection must be installed and evaluated for suitability by raising the load slightly and then lowering the load for an inspection of the sling and the protection devices. Several “test” lifts, inspections and evaluations may be necessary to determine the proper form of protection for a successful lift. Damaged or misused sling protection can result in sling failure. Inspect the sling protection before each use and remove if damaged. Be sure sling protection is the correct type and size to protect the sling. The length of the sleeve or protection material(s) must not interfere with the sling closing to the full gripping position on the load. Sling protection may not prevent cutting or other forms of damage. To avoid severe personal injury or death, personnel should be kept away from the load and never be under or near the load, while it is being lifted or suspended. Personnel should never be next to rigging that is under tension. Sling protection must be installed and evaluated for suitability by raising the load slightly and then lowering the load for an inspection of the sling and the protection devices. Several “test” lifts, inspections and evaluations may be necessary to determine the proper form of protection for a successful lift. Damaged or misused sling protection can result in sling failure. Inspect the sling protection before each use and remove if damaged. Be sure sling protection is the correct type and size to protect the sling. The length of the sleeve or protection material(s) must not interfere with the sling closing to the full gripping position on the load. Sling protection may not prevent cutting or other forms of damage. To avoid severe personal injury or death, personnel should be kept away from the load and never be under or near the load, while it is being lifted or suspended. Personnel should never be next to rigging that is under tension.

|

SLEEVES

Sleeves cover both sides of the sling and can be moved to a specific location. Sleeves can also be re-positioned for quick and easy inspection of the sling. Available in six different materials:

Bulked Nylon, Nylon, Leather, Neoprene, CornerMax® and Felt. Available in sewn edge, tubular and quick-sleeve constructions.

|

|

|

EYE WRAP

Eye Wrap at the bearing point is standard eye protection offered by Lift-It®. Sling eyes are wrapped with Bulked Nylon. Full length Eye Wrap is also available.

EYE BUFFER

If specified, Sling Eyes can be lined with Eye Buffers at the bearing point. The eye buffer can also be full length.

EYE SLEEVE

When additional protection is needed, consider Eye Sleeves. Hook and loop tape makes installation effortless and removal is quick and easy for inspection.

Please specify:

- Eye width and thickness

- Sleeve material

- Sleeve length

|

|

WEAR PADS

Wear pads are sewn to the sling for protection at specific wear areas. Wear Pads can be sewn at any location, in single or multiple layers and can be attached to one or both sides of the sling. Leather Wear Pads in excess of 5 feet are not recommended.

|

|

|

|

EDGE WRAP

Bulked Nylon or leather is sewn around the edge of the sling. Edge Wrap may be necessary in applications where abrasion damage occurs. Consider using Polyester Max Edge™ webbing.

|

|

|

|

BODY WRAP

Body Wrap is similar to the sleeve, but is sewn to a specific location. Body Wrap covers the webbing surface and the edges.

|

|

|

|

|

| Effects of "Minor" Edge Damage |

|

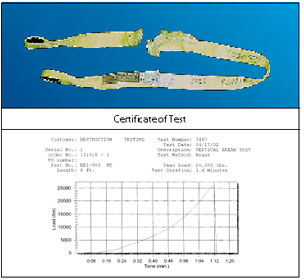

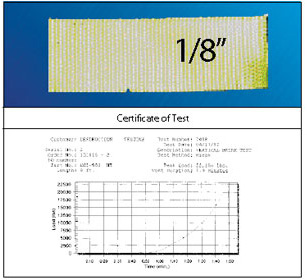

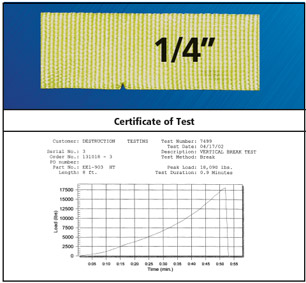

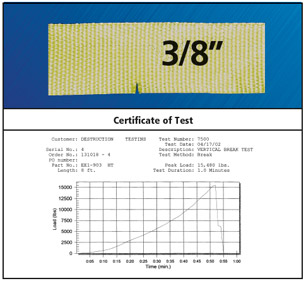

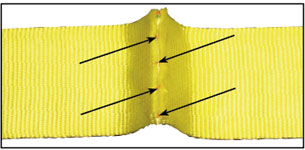

Four, identical, single ply slings were fabricated from a single roll of webbing. All independent variables were controlled, as the same thread, machine and fabricator were used for this experiment. The slings (EE1-903) are rated at 4800 Lbs. vertical and we would expect 24,000 Lbs. break strength. The slings were pulled to destruction. The control sling broke at 26,050 Lbs. The other three slings were deliberately cut on one edge to simulate: 1/8 inch, 1/4 inch and 3/8 inch cuts. This seemingly “minor” damage resulted in very significant strength loss.

“Minor” damage is extremely serious and damaged slings must be removed from service, immediately and not used for other applications. Remember, there is ZERO tolerance for sling damage. Be pro-active and prevent sling damage from occurring by employing suitable Sling Protection.

| Control Break - 26,050 LBS. |

|

1/8th" Cut - 22,150 LBS. |

|

|

|

| 1/4" Cut - 18,090 LBS. |

|

3/8th" Cut - 15,480 LBS. |

|

|

|

|

|

| Sling Design Features |

|

Four, identical, single ply slings were fabricated from a single roll of webbing. All independent variables were controlled, as the same thread, machine and fabricator were used for this experiment. The slings (EE1-903) are rated at 4800 Lbs. vertical and we would expect 24,000 Lbs. break strength. The slings were pulled to destruction. The control sling broke at 26,050 Lbs. The other three slings were deliberately cut on one edge to simulate: 1/8 inch, 1/4 inch and 3/8 inch cuts. This seemingly “minor” damage resulted in very significant strength loss.

“Minor” damage is extremely serious and damaged slings must be removed from service, immediately and not used for other applications. Remember, there is ZERO tolerance for sling damage. Be pro-active and prevent sling damage from occurring by employing suitable Sling Protection.

|

|

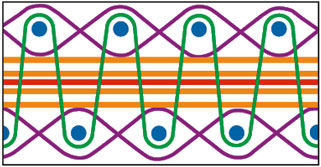

Sling WebRing

|

|

PURPLE: Surface (Weft) yarns carry a portion of the load.

ORANGE: Longitudinal (Warp) yarns carry the majority of the load.

RED: Red core yarns.

BLUE: Lateral yarns woven into the surface yarns.

GREEN: Binder yarns secure the surface and core yarns.

|

|

Lift-It® web slings are fabricated from sling webbing. Sling webbing features a “stuffer” weave construction, where the inner load carrying yarns are jacketed by a protective outer cover. The longitudinal load yarns carry approximately 70% of the load, while the remaining strength is derived from the cover (side-toside) yarns. Red core warning yarns are woven into the central load carrying area. The red core yarns may become visible, as the outer cover is worn away or becomes damaged, providing a signal to users and inspectors to remove the sling from service.

In many applications, slings become extremely dirty, making it difficult to see the red core yarns. Red core yarns cannot be used exclusively to determine the condition of the sling. Red core yarns must be used in conjunction with other removal from service criteria and visual/tactile inspection techniques to determine sling condition. If there is any doubt, do not use the sling. In many applications, slings become extremely dirty, making it difficult to see the red core yarns. Red core yarns cannot be used exclusively to determine the condition of the sling. Red core yarns must be used in conjunction with other removal from service criteria and visual/tactile inspection techniques to determine sling condition. If there is any doubt, do not use the sling.

|

|

MIL-Spec WebRing

|

|

RED: Load carrying surface yarns.

YELLOW: Load carrying surface yarns.

BLUE: Load carrying binder yarns.

|

|

Military specification or “Mil-Spec” webbing is not designed for lifting. Nothing prevents its use in lifting applications, but educated, informed sling purchasers, users and inspectors. “Mil-Spec” webbing does not feature red core yarns and does not employ a stuffer weave design. Since the load carrying yarns are surface exposed, the tensile strength of Mil-Spec webbing, subjected to minor surface damage is radically reduced.

Why would a manufacturer supply “MIL-SPEC” or tie down web for a lifting assembly? The answer is simple, to maximize profit margin. Our problem with that is your safety is compromised.

|

|

Effects of Surface Abrasion

|

|

Red Core Yarn Sensibility

|

|

DESCRIPTION

|

SLING

WEBBING

|

"MIL-SPEC"

WEBBING

|

|

MATERIAL

|

NYLON

|

NYLON

|

|

WIDTH

|

2 IN.

|

1-3/4 IN.

|

|

THICKNESS

|

.12 - .14

|

.15 - .18

|

|

RED CORE YARN

|

YES

|

NO

|

|

FINISH

|

PIGMENT DYE

|

CONDITION "U"

|

|

UNSEWN TENSILE

STRENGTH

|

15,000 Lbs.

|

15,000 Lbs.

|

|

DAMAGE

DESCRIPTION

|

HEAVY

ABRASION

|

LIGHT

ABRASION

|

|

TENSILE STRENGTH

AFTER DAMAGE

|

7,000 Lbs.

|

1,900 Lbs.

|

|

% LOSS

|

53%

|

87%

|

|

WEAR OR DAMAGE TO COVER YARNS OF SLING WEBBING RESULTS IN IMMEDIATE STRENGTH LOSS. WEAR OR DAMAGE TO COVER YARNS OF SLING WEBBING RESULTS IN IMMEDIATE STRENGTH LOSS.

|

|

|

Do not operate under the misconceptions, “If I see red, I’ll be dead” or the red yarns “pop out at you” when the sling is not safe to use or during lifting to alert users of overloading. Pay attention to the many, other removal from service criteria and be a responsible user and inspector.

DO NOT USE SLINGS THAT ARE STRUCTURALLY DAMAGED, IF RED CORE YARNS ARE NOT VISIBLE. DO NOT USE SLINGS THAT ARE STRUCTURALLY DAMAGED, IF RED CORE YARNS ARE NOT VISIBLE.

|

|

Manufacturing Tolerance

|

|

All Lift-It® web slings are manufactured to the following tolerances. For Web slings wider than 6 inches, add 1/2” to the following values. For exact tolerances or matched slings, contact us

|

Sling Thickness

|

Tolerance

|

|

1 Ply

|

1.5 Inches + 1.5% of Sling Length

|

|

2 Ply

|

2.0 Inches + 2% of Sling Length

|

|

3 & 4 Ply

|

3.0 Inches + 3% of Sling Length

|

TREATED WEBBING

Lift-It® slings are manufactured from industrial sling webbing that has been treated in the final stages of looming. The treatment helps seal out moisture and dirt, reducing the effects of abrasion, while enhancing sling service life. Untreated web slings are also available upon request.

|

|

DESIGN FACTOR

All NEW Lift-It® slings are designed and rated with a Design Factor of 5 to 1, unless otherwise stated. When specified, other Design Factors are available. Our slings can be used in compliance with OSHA and ASME specifications. The Design Factor does not allow the user to exceed the Work Load Limit. It is important for sling users to realize Work Load Limits are based upon: destruction testing done in laboratory controlled, testing conditions that will never be duplicated during actual usage and the sling being in a new or “as new” condition.

Any instantaneous change (sudden drops or rapid acceleration) constitutes hazardous shock loading and THE WORK LOAD LIMITS AS STATED, DO NOT APPLY.

|

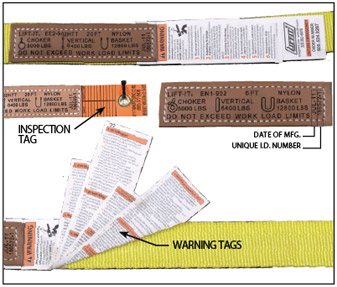

| Sling & Warning Tags |

|

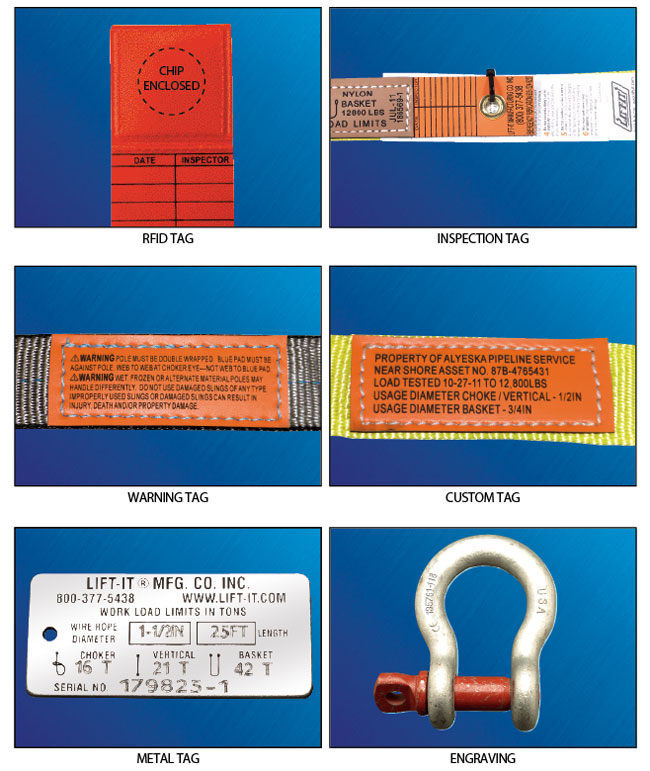

A heavy duty tag is attached to all slings. All necessary information required by the various regulatory agencies is laser imprinted into synthetic leather, resulting in the most durable tag available.

Hitch diagrams, date of manufacture and a unique sling identification number are also included. Custom tags can also be attached for a nominal charge.

In addition to the sling tag, a warning tag is also attached. Developed by the Web Sling and Tie Down Association, it contains important safety, use and inspection information, including removal from service criteria.

Durable, Synthetic Inspection Tags include a matrix for memorialization and visual verification of periodic sling inspections. Synthetic Inspection Tags are available on request for an additional charge.

Proper use, care, inspection and accident prevention measures are enhanced by the Lift-It® Sling and Warning Tag System. If the Sling or Warning Tag becomes detached or illegible, return to us for re-labeling.

|

|

|

|

|

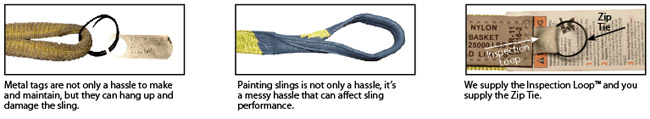

Lift-It Inspection Loop

|

|

|

Slings must be inspected at different levels and at specified times. How does one visually validate that the periodic inspection, done at least annually, has been done?

Sling Inspectors may meticulously track individual slings and rigging equipment, recording the condition. A unique identification number would be necessary to differentiate identical slings or equipment.

Some inspectors dip the sling into paint (not only a hassle, but a messy hassle) to “visually” signify that the periodic inspection was done. Others attach metal tags that are not only time consuming to make and attach, but could damage the sling by hanging up during use. Zip Ties and colored, electrical tape are also used, but if they are attached too snuggly, they too can cause damage and affect sling strength.

The Lift-It® Inspection Loop™ does not damage slings or components. We supply the Inspection Loop™ and you supply the colorized zip tie denoting the specific inspection interval (month, quarter or year). Imagine the simple beauty of visually surveying multiple slings and easily determining that slings had been inspected during a specific time period. All you need to do is specify, “Inspection Loop” on your order to take the first step to inspection efficiency.

|

|

|

| Sling Tags & Engraving: Inspection, Warning, Custom & RFID |

|

In addition to the Lift-It® Inspection Loop there are several other ways to visually validate that the periodic inspection has been done. We also offer custom, engraved metal tags. Shackles and other fittings that have a flattened area can also be engraved.

|

|

|

|

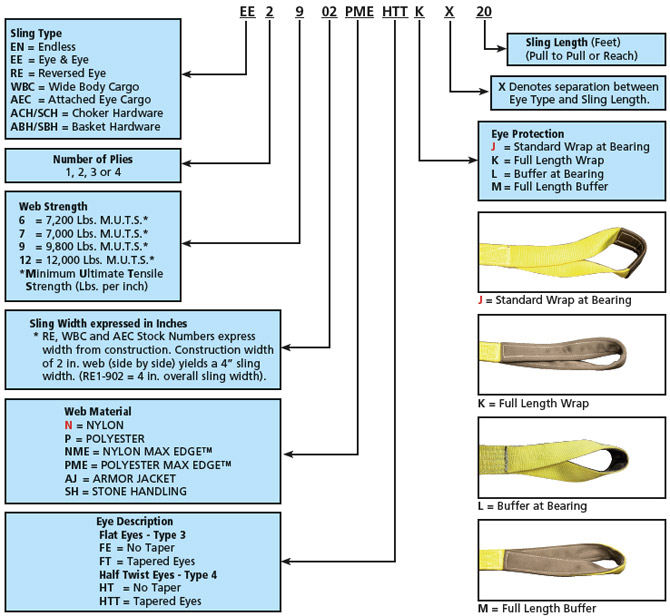

| How to Order Slings |

|

All orders must specify:

- Complete Stock Number.

- Web Description, (if applicable): Polyester, Polyester Max Edge™, Nylon Max Edge™, Armor Jacket or Stone Handling Web. If regular Nylon web is desired, no suffix is required.

- Eye Type and Eye Protection Description, (If applicable).

- Standard eye protection is Option J and need not be included in the Stock Number.

- Options K, L or M are available and must be included in the Stock Number.

- Dimensional Information: Sling Width and Length.

- Sling Protection:

- Description, location, quantity and length of Protection Pads and/or Sleeves.

- Refer to "Sling Info Sheet" here or under "Product Resources"

- Attachments and Accessories

- Ordering instructions and warnings are featured in the individual catalog sections.

- Please note: All items are custom made and non-returnable.

|

|

|

|