|

Read and understand the important, safety information that follows and the information contained in this publication and follow OSHA, ASME, Association, Industry and Manufacturer guidelines. Rigging and manipulating loads involves more than attaching equipment and raising the load. There are certain hazards that cannot be mitigated by engineered features, but only by the exercise of intelligence, care, common sense and experience in anticipating the effects and results of rigging any load with any type of equipment. Use this guidance in conjunction with the warnings, cautions and safety instructions supplied with all products. If you do not receive this information, contact us for additional copies or visit www.lift-it.com Read and understand the important, safety information that follows and the information contained in this publication and follow OSHA, ASME, Association, Industry and Manufacturer guidelines. Rigging and manipulating loads involves more than attaching equipment and raising the load. There are certain hazards that cannot be mitigated by engineered features, but only by the exercise of intelligence, care, common sense and experience in anticipating the effects and results of rigging any load with any type of equipment. Use this guidance in conjunction with the warnings, cautions and safety instructions supplied with all products. If you do not receive this information, contact us for additional copies or visit www.lift-it.com

All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations. All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations.

Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable, or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others. Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable, or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others.

Our Catalog DOES NOT contain all the information you need to know about handling and manipulating materials and loads safely. Sling use is only one part of a lifting system and it is your responsibility to consider all risk factors prior to using any rigging device or product. Failure to do this may result in severe INJURY or DEATH due to sling or equipment failure and/or loss of the load. Our Catalog DOES NOT contain all the information you need to know about handling and manipulating materials and loads safely. Sling use is only one part of a lifting system and it is your responsibility to consider all risk factors prior to using any rigging device or product. Failure to do this may result in severe INJURY or DEATH due to sling or equipment failure and/or loss of the load.

Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and Rigging products will fail if damaged, abused, misused, overused or improperly maintained. Regular inspection must be conducted to determine if any product can be used at the assigned Work Load Limit (WLL) or whether the product shall be removed from service. OSHA and ASME stipulate that a visual inspection of the sling must be made daily or before each shift in Normal service conditions. In addition, Web Sling and Tie Down Association recommends that slings be inspected prior to each use in Severe service conditions. If you are unsure if the required inspection has been done for either service condition, take the time to inspect slings prior to use. Slings that are damaged or determined to be unsafe shall not be used for any application. Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and Rigging products will fail if damaged, abused, misused, overused or improperly maintained. Regular inspection must be conducted to determine if any product can be used at the assigned Work Load Limit (WLL) or whether the product shall be removed from service. OSHA and ASME stipulate that a visual inspection of the sling must be made daily or before each shift in Normal service conditions. In addition, Web Sling and Tie Down Association recommends that slings be inspected prior to each use in Severe service conditions. If you are unsure if the required inspection has been done for either service condition, take the time to inspect slings prior to use. Slings that are damaged or determined to be unsafe shall not be used for any application.

All Work Load Limits (WLL) indicated in our catalog are applicable only to new or “in as new” condition products. The Work Load Limits indicate the greatest force or load a device can carry under normal circumstances. Work Load Limits are based upon destruction testing, done in controlled, laboratory conditions, which will never be duplicated during actual usage. Any instantaneous change (sudden drops or rapid acceleration) constitutes hazardous shock loading and THE WORK LOAD LIMITS AS STATED, DO NOT APPLY. Shock loading, side loading and extraordinary or unique conditions must be taken into account when using any device in a rigging system. All Work Load Limits (WLL) indicated in our catalog are applicable only to new or “in as new” condition products. The Work Load Limits indicate the greatest force or load a device can carry under normal circumstances. Work Load Limits are based upon destruction testing, done in controlled, laboratory conditions, which will never be duplicated during actual usage. Any instantaneous change (sudden drops or rapid acceleration) constitutes hazardous shock loading and THE WORK LOAD LIMITS AS STATED, DO NOT APPLY. Shock loading, side loading and extraordinary or unique conditions must be taken into account when using any device in a rigging system.

Our Products may contain chemicals known to cause cancer, birth defects and/or other reproductive harm. Our Products may contain chemicals known to cause cancer, birth defects and/or other reproductive harm.

Please note that information developed by the Web Sling and Tie Down Association (WSTDA) relative to warnings is included in our catalog with the permission of the WSTDA. This information is © WSTDA-2010.

|

|

If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only. If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only.

|

|

Slings can be damaged, abraded or cut as tension and compression between the sling, the connection points and the load develops. Surfaces in contact with the sling do not have to be very abrasive or have “razor” sharp edges in order to create the conditions for sling failure. Therefore, roundslings must ALWAYS be protected from being cut or damaged by corners, protrusions or from contact with edges that are not smooth or well-rounded with materials sufficient for the intended purpose.

There are a variety of ways to protect slings from such damage. A qualified person might select and use appropriately engineered protectors/softeners, commercially available products (i.e., sleeves, wear pads, corner protectors, etc.), specifically designed to protect slings from damage. A qualified person might also design and construct methods of protection so long as the sling is adequately protected from and/or kept off of the damaging edge surface.

Regardless of the particular method chosen, the goal is to ensure that the sling, under tension, maintains its ability to securely lift the load while avoiding contact with damaging or abrasive surfaces under tension. A qualified person must carefully consider the most appropriate means to accomplish this goal. The protection used should not be makeshift (i.e., selecting and using cardboard, work gloves or other such items based solely on convenience or availability).

Regardless of the approach taken, a qualified person must ensure that the protection method chosen is appropriate for the types of damage to which the slings will be exposed. For instance, some protection provides abrasion resistance, but offers virtually no protection against cuts. Several “test” lifts, done in a non-consequence setting, may be necessary to determine the suitability of the protection device(s). After each “test” lift, the protection device(s) and sling(s) need to be inspected for damage and suitability. You should keep in mind that no protection is “cut proof” and you should always operate within the specified limits of the sling and its accessories (i.e., fixtures, hardware, protection, etc.).

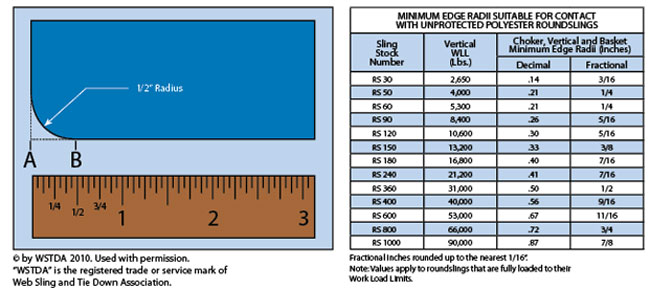

The Web Sling and Tie Down Association has conducted testing to determine the effects of edge curvature on three sizes of roundslings over different radii. Hundreds of slings from five different manufacturers were pulled to destruction resulting in recommendations for minimum edge radii suitable for contact with unprotected polyester roundslings. Please consider that the testing was done in laboratory conditions under controlled circumstances, with full, perpendicular contact made between the sling and the simulated edge. If roundslings are used at angles where full, 90 degree, perpendicular contact between the load edge and sling is not made; the suggested recommendations may not apply. If there is any doubt, use protection and evaluate as specified above.

Roundslings must always be protected from coming into direct contact with any edges unless the contacting edges meet both of the following criteria:

- The edges must be smooth and well-rounded.

Edges that are chamfered or flattened at an angle do not meet this criterion.

- The size of the edge radii must be adequately large.

The following table shows the minimum edge radii suitable for contact with unprotected polyester roundslings.

One way to determine an edge radius is to measure the distance between the leading edge of the radius (Point A) and the point where the radius initiates from the bottom edge of the surface (Point B).

|

|

In order to protect the roundsling, it is necessary to select and use proper connection hardware. Connection hardware should be selected so that either:

- It conforms to the size requirements listed in the roundsling product specifications. (See page 106).

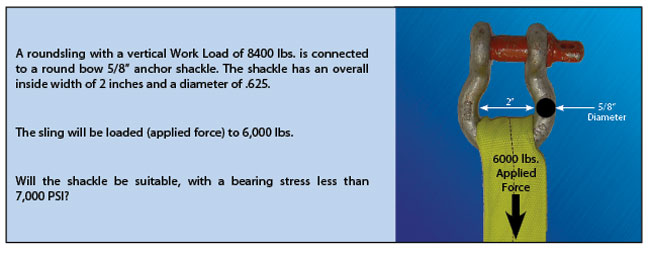

- The bearing stress value at the connection does not exceed 7,000 lbs. PSI during sling loading.

Lift-It® Roundsling product specifications reflect minimum hardware diameters for polyester roundslings. These recommendations are the result of testing and analysis done by the Roundsling Technical Committee, Web Sling and Tie Down Association. Minimum diameter recommendations and other important information can be found in the Recommended Standard Specification for Synthetic Polyester Roundslings (WSTDA- RS-1).

Another approach to determine the correct relationship between roundslings and connection hardware is also found in the abovementioned specification. This method establishes a maximum bearing stress at 7000 PSI and provides instruction in calculating bearing stress.

Slings are subjected to compression and tension during loading. Lower compressive forces result in higher sling breaking strengths. Likewise, higher compressive forces result in lower sling breaking strengths.

Damage at sling connection points is a result of pressures exceeding the maximum allowable compression limit per square unit of exposed surface area.

The first step to determine the bearing stress is to calculate the LOAD BEARING AREA. To accomplish this, the effective contact width must be calculated. The effective contact width for straight bearing surfaces equals 100% of the actual inside width of the connection point. The effective contact width for curved bearing surfaces is 75% of the overall inside width of the connection point.

Next multiply the effective contact width by the fitting diameter. The product obtained is the LOAD BEARING AREA. Once the LOAD BEARING AREA has been calculated, divide the APPLIED FORCE by the LOAD BEARING AREA to determine the BEARING STRESS.

|

|

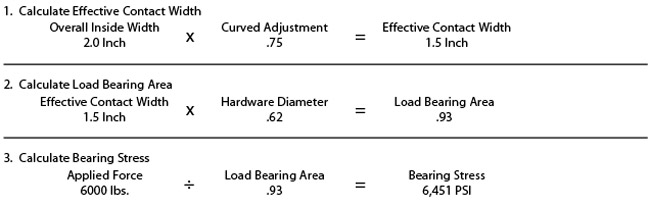

Lift-It® Polyester Roundslings are made of polyester core yarn covered by a seamless, tubular cover. The seamless construction and tubular design of the cover helps to eliminate the premature rupturing of covers, characteristic of seamed roundslings.

- Since the core yarns are not directly in contact with the load there is no loss of strength from abrasion to the sling cover.

- Endless configurations enable the user to rotate hook and load contact points, resulting in increased sling longevity.

- Because the sling body is soft and pliable, it will not choke lock, hindering removal.

- Multiple polyester roundslings are manufactured simultaneously, resulting in increased production efficiency and cost savings, when compared to equivalent strength web slings.

It’s important in a global economy to remain competitive without compromising safety. To that end we have established relationships with foreign partners and offer our import line of roundslings. Available with Double Polyester covers our imported roundslings are made to the same specifications and standards as our domestic products. On site management and supervision at our foreign facility, coupled with testing at our US locations ensures quality and cost efficiency for your bottom line. Our import line will feature the same tagging, tracability, unique serial numbers and all other features that you have come to expect as standard procedures at Lift-It®. One striking difference between us and others is that we will not sell you an import masquerading as a domestic product. Stock numbers indicate an imported product, i.e., RS90I.

|

| LIFt-IT® ROUNDSLING COVER SELECTIONS |

|

|

| HOW TO ORDER |

|

All orders must specify:

- COMPLETE STOCK NUMBER

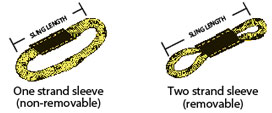

- SLING LENGTH: Unless otherwise specified:

Sling lengths are measured as bearing to bearing lengths.

Assembly lengths are measured as bearing hardware.

- FITTING DESCRIPTION

- SLING PROTECTION:

Description, quantity and length of sling protection.

|

|

|

|

|