Significant improvements have been made to the equipment used in load handling and load securement activities. In 1973 it would have seemed unimaginable that years later, synthetic slings with an ultimate break strength of 1,360,777 kgs weighing only 15.62 kgs per meter would be readily available.

High performance fibers Kevlar®, Spectra® and Dyneema® are used as strength members for high performance synthetic ropes and roundslings, and crane boom hoist and pendant lines. The use of high-performance fibers has not only improved efficiency but enhanced user safety.

When textile chain made from DSM Dyneema® - DM20 fiber became available, early adopters recognized the inherent value and benefits. The combination of strength-to-weight ratio advantage while impressive was not new. Thirty years ago, high performance fiber Twin-Path® Extra slings replaced heavy, cumbersome, injurious wire rope slings.

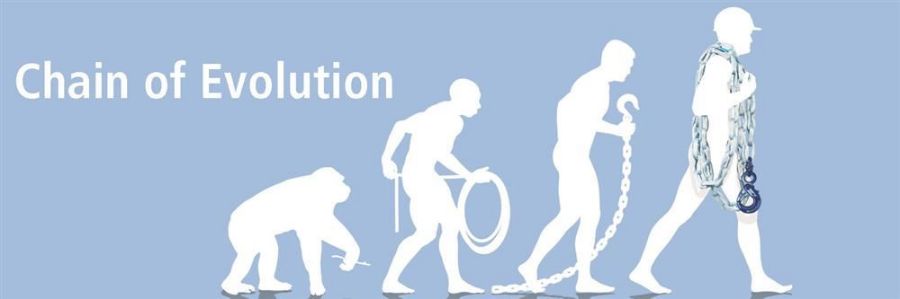

Textile Chain combines ultra-light strength with adjustability taking the “Chain of Evolution” up several notches. Quick and easy leg length adjustment for Tycan® Chain Assemblies is done via Shortening Hooks with multiple advantages.

One adjustable Tycan® synthetic sling assembly easily replaces multiple fixed length slings reducing inventory. “Synthetic” adjustability makes turnbuckles a less attractive option and riggers no longer have to add or take away shackles to adjust leg lengths. The need to inventory and carry extra equipment, coupled with incredible time savings makes the value proposition for Tycan® synthetic chain slings an undisputable one.

®Tycan® textile chain slings are available in single, double, triple, and quad leg assemblies. A quad-leg bridle assembly fabricated from 13x30 Chain has an assembly capacity of 23,366 Lbs. at a 60-degree angle of loading.

Substantial time and money are saved when textile adjustable chain slings are used to rig asymmetrical loads or when cranes are not an option and bull rigging is used. Jobs that normally took two people several hours are now accomplished by a single person in a matter of minutes.

Load securement users can easily carry a 60-foot length of Tycan® synthetic lashing chain; try doing that with “heavy metal” chain.

Tycan® Textile Lashing Chain is an efficient and cost-effective alternative for multiple reasons:

* Faster Lashing & Release: Tycan® Chain is easily handled by personnel without cranes or ladders.

* Increased Safety: Workers do not need to climb ladders and walk over cargo.

* One person can handle Tycan® Lashing Chain with much less fatigue when compared to steel chains.

* Strength & Elongation: Identical to steel chain. 16m long Tycan® Chain (20 tonnes MBL) weighs only 10.2kg.

* Steel lashing tends to slide off cargo falling onto cargo decks. Time and money are wasted recovering.

* Synthetic Tycan® Lashing Chain reduces damage to cargo.

Tremendous savings from decreased port time is facilitated by improved efficiencies (less time for lashing and releasing cargo and more done in less time with less personnel). These savings are also boosted by other factors that may not be so readily apparent. Considerable funds are saved when damage claims, medical treatment, rehabilitation, and skyrocketing insurance claims do not occur.

One cannot refute the inherent value proposition of Tycan® Synthetic Lashing Chain.

Not only have remarkable advances been made in devices used for load handling and securement, but significant improvements in safety have occurred as users are trained in the proper use of slings and tie downs. To appreciate the progress, one must first consider the term “product failure”. Many rigging manufacturers have been contacted by a customer claiming that a sling or tie down “failed”.

Slings and tie downs may be damaged when contact occurs with potentially damaging corners (that need not be “razor” sharp) or with surfaces that are not excessively abrasive. Tension and compression “join forces” making a seemingly innocuous surface or edge one that may damage and sever sling or tie down strength components, i.e., chain, wire rope, synthetic rope, webbing or roundsling core yarns.

Add “movement” to tension and compression, and SERIOUS INJURY and/or DEATH may occur.

Movement = non-positive engagement whereby slings or tie downs slide across load edges/surfaces and/or the load slips and slides across slings or tie downs.

Abrasion damage (the mechanical wearing or scuffing of surfaces from frictional movement between two objects) can occur as slings or tie downs are subjected to tension, movement and/or vibration. The cause and appearance of abrasion damage vastly differs from cutting damage.

Cutting and abrasion damage from misuse are often incorrectly referred to as “product failures”.

When slings or tie downs are destruction tested, the tensile break of synthetic strength components does not manifest itself in the square end (linear) fiber separation of thousands of many small, independent fibers that are less than the diameter of a human hair.

When synthetic slings and tie downs are pulled to destruction the tensile break resembles an explosion of yarn fibers and NEVER resembles a linear “cut” of countless yarn fibers with square end (linear) fiber separation, occurring simultaneously!

Square end (linear) fiber separation and/or abrasion degradation is a direct result of contact with damaging edges, corners, or surfaces. Protecting slings and tie downs with materials of sufficient strength, thickness and construction from cutting and abrasion damage is a very vital part of proper usage and is mandated by various regulations and guidelines.

Rags, gloves, cardboard, carpet, and fire hose are not sling protection options for properly trained users and/or qualified persons. These items were not made with the intent for use as protection devices and were not tested or evaluated for adequacy for sling protection regulatory adequacy or compliance.

Slings and/or protection that is “cut proof” do not exist. Cut resistant sling protection does, but it must be properly used to prevent damage. Manufacturers must provide ratings, information on the proper use, inspection, and removal from service criteria for slings and tie downs. Doesn’t it seem logical that sling protection manufactures provide the same information for sling protection devices? Otherwise sling users are forced to determine sling protection adequacy through a trial and error process with no guarantee of repeatability.

The safety and training professionals at Lift-It Manufacturing constantly evaluate event incidents and litigation to adjust their training program to address performance gaps and has completed a 3-year sling protection project. Five different types of sling protection were tested and labelling, inspection, removal criteria and training were developed.

Sling users, industry experts, safety and training professionals provided input which was used by a Human Factors Expert to develop five separate

sling protection user manuals. The user manuals contain warnings and guidance for proper use and inspection of sling protection and are

available in English and Spanish versions.

Lift-It safety and training professionals have promoted sling protection for 41 years. The copyrighted Lift-It sling protection user manuals have been donated to the Web Sling and Tie Down Association (WSTDA) and hopefully will serve as the genesis for a WSTDA Sling Protection Safety Standard.

Based upon recent events it appears that sling protection training efforts have produced positive results. Incidents of injury and/or death from the absence and/or inadequacy of sling protection are decreasing. Unfortunately, reports of injury and death from working in the fall zone are increasing.

The U.S. Department of Labor – Occupational Safety & Health Administration in 29CFR 1926.1401 defines the fall zone as, “The area, including but not limited to, directly below the load in which it is reasonably foreseeable that partially or completely suspended materials could fall in the event of an accident”. While the fall zone definition addresses the consequences falling loads it does address the dangers of an unplanned release of tension of rigging or securement devices used in non-vertical, i.e., horizontal attitudes.

An unplanned release of tension can produce devastating whiplash and/or impact force as broken rigging or lashing components are propelled at hundreds of feet per second in unpredictable directions striking personnel.

An effective warning must not only identify the hazard but recommend appropriate measures to mitigate the hazard and/or clearly state the consequence of not addressing the hazard, i.e., SEVERE INJURY or DEATH.

A human factors expert, utilizing focus groups determined the best term to use was “Danger Zone”.

It was also determined that symbols be used to not only transcend language and literacy barriers but enhance comprehension of the hazard. Brevity is not only the soul of wit, but the efficacy of an effective warning. NEVER UNDER – NEVER ON – NEVER IN-LINE combined with graphics designed for load handling (lifting) and load securement (lashing) were evaluated, reviewed, and developed.

A 9mm socket dropped from a wind turbine nacelle can be just as deadly as a 500-ton dropped load. Gravity always works, certainly what goes up, must come down. While the direction of broken rigging is unpredictable, the consequences of any unplanned release of built up tension can be devasting.

Michael J. Gelskey, Sr. is the CEO and founder of Lift-It® Manufacturing Co., Inc. – Pomona, CA.

He has been involved in the design and manufacture of slings and tie downs for 47 years.

He currently serves as a committee member of the American Society of Mechanical Engineers

B30.9 Sling Committee, the Associated Wire Rope Technical Committee, the Web Sling and Tie Down Association Web Sling and Roundsling Committees and chairs the WSTDA Legal Resource Committee. He has presented hundreds of training sessions for sling users, sling and rigging gear inspectors, trade, industry, association, and regulatory groups and provides safety and professional development courses for training and safety personnel.

Lift-It® is a recognized leader in the sling and rigging industry and for 41 years has provided the finest rigging products available. Lift-It safety professionals provide LEEA accredited training programs.

Additional information for Tycan® synthetic chain, sling protection user manuals and/or training is available by emailing info@lift-it.com.

You can also read the article in its entirety at Lift and Hoist International.