|

The The  Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations. Icon, used in our product information is done to alert sling users to potentially hazardous conditions and situations.

It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous It is your explicit responsibility to consider all risk factors prior to using any rigging device or product. Read and understand the information contained in this bulletin, in our catalog, on our website www.lift-it.com and follow OSHA and ASME guidelines. Use by untrained persons is hazardous

The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard, clearly establishes the requirement for training. Section 9-4.1-Training states, “Synthetic rope sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.” The American Society of Mechanical Engineers, in the ASME B30.9 Sling Safety Standard, clearly establishes the requirement for training. Section 9-4.1-Training states, “Synthetic rope sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices, covered by this chapter.”

All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations. All Products provided by Lift-It® Manufacturing Co. Inc. are sold with the express understanding that the purchaser and user are thoroughly familiar with the safe and proper use and application of the product. The user has the responsibility for proper use and application as outlined in all applicable standards and regulations.

Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others. Use by untrained persons is hazardous. It is important that all sling and rigging users be thoroughly familiar with the manufacturer’s recommendations and safety information that accompany the products. The user must have sufficient training and knowledge of all applicable standards to responsibly use our products. If you are unsure whether you are properly trained and knowledgeable or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training. DO NOT use any sling or rigging device until you are absolutely sure of what you are doing. Remember, when it comes to using slings and rigging devices, lack of skill, knowledge and care can result in severe INJURY or DEATH to you and others.

Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained. Failure to follow proper use, care and inspection criteria could result in severe personal injury or death. Slings and rigging products will fail if damaged, abused, misused, overused, or improperly maintained.

|

|

Any hazardous condition disclosed by an inspection shall require sling replacement. Temporary repairs are not permitted. Damage and wear seriously reduce sling Work Load Limits.

Always know the load weight and select the appropriate sling for the load, configuration of lift necessary to ensure load control and any chemical exposure.

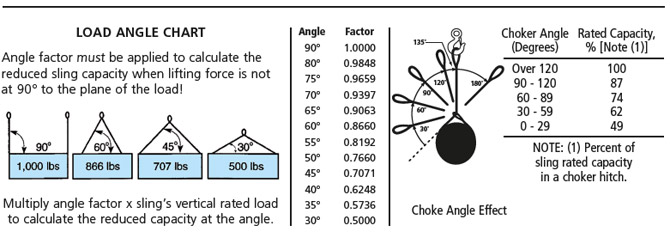

Always take into account sling angles to calculate changes in the sling Work Load Limits, when used in choker and non-perpendicular vertical, basket or bridle configurations.

Ensure that the load will not cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces with suitable materials of sufficient strength, thickness and construction.

The strength of synthetic rope slings can be affected by chemically active environments. Sling materials may be susceptible to damage from caustic or acid substances or fumes. Strong oxidizing environments attack all common sling materials and components. Consult the manufacturer prior to selection and use.

Absorbed moisture or impurities will dramatically increase the conductivity of the rope.

Dynamic loading affects ropes with less stretch, to a greater degree, than ropes that have greater elongation properties. Likewise, a shorter length rope is more profoundly affected by dynamic loading, than a longer length rope.

Lifts can be made with any two or three legs of the four leg, Adjustable Rope Sling, if it has a Masterlink or Masterlink with subassembly. If three of the four legs are used, the assembly Work Load Limit must be reduced by 33% and is effectively the same work load as a two leg (double) sling.

|

|

|

| INSTRUCTIONS FOR CARE, USE, INSPECTION, & REPAIR |

CARE

Store away from possible mechanical damage, corrosion, dust, grit, extreme temperatures, sun and any ultraviolet light source. Exposure to sunlight will reduce the strength of synthetic slings. Polyester rope slings lose 30% of sling strength after 12 months of constant exposure; nylon rope slings lose 40% to 60% of sling strength after a 12 to 36 month constant exposure period.

USE

Know the weight of load. Check tag to confirm that sling is rated adequately for the load (see load angle chart). Sling shall not be twisted, tied into knots or joined by knotting. Shackles and other hardware must be inspected and padded if there are edges that could damage the sling. Be sure that the load can’t cut the sling during the lift by padding corners, edges, protrusions or abrasive surfaces; use materials of sufficient strength, thickness and construction. Center sling in the base (bowl) of hook unless hook is designed for point loading. Balance the load. Maintain load control. Avoid jerking the load. Be alert for snagging of load Do not pull on stuck objects. Avoid dragging sling over rough surfaces and from under the load. Choker hitch must choke on rope, never on a splice or end fitting. Stand clear of load at all times. Persons are not to ride on sling or load. For use in abnormal conditions of heat, cold, chemical activity, consult the manufacturer. Rope slings must be used with compatible fittings, hooks and shackles. Bunching of rope reduces capacity. Avoid exposure to acid, alkali or sunlight. Do not use synthetic rope slings at temperatures above 180º F or below -40º F. Pad edges of load to avoid damage to the synthetic rope sling.

INSPECTION

Before each use: Check tag to confirm that sling is rated adequately for the load. Inspect rope for cuts, areas of extensive fiber breakage or abrasion along the length of rope. Check for a reduction of no more than 10% of the rope diameter or if covered by fuzz or whiskers. Inspect the inside of the rope for broken or melted fibers for no more than 10% of the fiber in any strand. Inspect hardware for distorted, cracked, worn fittings. If this wear or damage is present or if the rated load tag is missing or illegible, remove from service and repair or replace sling. Frequent inspection is done by the person handling the sling before each use and must include all of the before use items. Periodic Inspections are required at least annually for normal service, quarterly or more frequently if in severe service or nearly constant use. Periodic inspections are performed by designated person(s) who are trained and a written record of the most periodic inspection shall be maintained. The inspector shall determine when further use would be hazardous.

REPAIR

If any hazardous condition is disclosed during an inspection, the sling shall be removed from service for repair or replacement. Field repair is not permitted. Only manufacturers or qualified persons may make repairs. All repaired slings must be proof tested and certified.

|

|

|

Because of the reduced lifting capacity, use extra care when the horizontal lift angle is less than 45° and do not make lifts of less than 30° load angle. Example: A sling with adequate capacity could be broken because of increased tension resulting from angles of less than 30 degrees. When possible, use longer slings to minimize angular tension by increasing the angle.

|

| Adjustable Rope Slings Considerations |

ABRASION:

Avoid all abrasive conditions. Adjustable Rope Slings may be severely damaged if subjected to rough surfaces or damaging edges. Lifting hardware and attachment points must be maintained in good condition and kept free of burrs and rust. Do not drag Adjustable Rope Slings over the floor, ground or over rough surfaces. Dirt and grit can work into the strands, damaging the internal fibers. Look closely at both the inner and outer fibers. When either is worn the rope is weakened. Open the strands and inspect for powdered fiber, indicating internal wear. Examine the internal wear to estimate total fiber loss. Protect slings from cutting and abrasion with sling protection that is the correct size and type. Refer to Sling Info Sheet.

CHEMICALS:

Avoid exposing Adjustable Rope Slings to damaging chemicals. Take into consideration: chemical exposure, such as solvents, acids, alkalis or where fumes, vapors or mists are present. Consult us prior to purchase or use.

DISCOLORATION:

With use, all rope slings become dirty. Areas of discoloration may also indicate chemical damage. Determine the cause of the discoloration and if chemical degradation has occurred, remove the sling from service.

TEMPERATURE:

Adjustable Rope Slings have lower tensile strengths and Work Load Limits at elevated temperatures. Continued exposure at elevated levels may melt, part or cause permanent damage. Do not use at temperatures above 180°(F)/82°(C) or below -40°(F)/ -40°(C). Glossy or glazed areas are evidence of heat damage and experience more strength loss than is visibly evident. Fibers adjacent to the heat damaged areas may appear normal, but are not.

CARE and STORAGE:

Adjustable Rope Slings should be stored in a clean, dry area out of direct sunlight and away from sources of extreme heat. The storage location should also be free of environmental and mechanical damage.

INCONSISTENT DIAMETER:

Inspect for flat areas, bumps or lumps, as they can indicate core or internal damage from overloading or shock loading. If these forms of damage are evident replace the sling and do not use damaged slings for any application.

|

|

|

Absorbed moisture or impurities will dramatically increase the conductivity of the rope.

It is dangerous if personnel are in line with a rope under tension. Rope failure can result in a deadly recoil force. Personnel should never be under a rope sling or suspended load.

Work Load Limits are based on a moderately dynamic lifting or pulling operation. Instantaneous changes (rapid acceleration or sudden stops) constitute hazardous shock loading and Work Load Limits as stated DO NOT APPLY.

Dynamic loading affects ropes with less stretch, to a greater degree, when compared to ropes that have greater elongation properties. Likewise, a shorter rope is more profoundly affected by dynamic loading than a longer rope.

Lift-It® Adjustable Rope Sling capacities are lower than our competitors. The Work Load Limit of four Leg slings is based upon three legs carrying the load. Our conservative approach is respected by conscientious users and appreciated by sophisticated purchasers.

Lifts can be made with any two or three legs of the four leg, Adjustable Rope Sling, if it has a Masterlink or Masterlink with subassembly. If three of the four legs are used, the assembly Work Load Limit must be reduced by 33% and is effectively the same work load as a two leg (double) sling.

|

|

Can fail if damaged, misused or overloaded. Inspect before use. Use by untrained personnel is hazardous. Observe and do not exceed Work Load Limits. DEATH and INJURY can occur from improper use or maintenance. Refer to the following for Important Safety, Use and Inspection Information. Safety Information and Inspection & Removal. Can fail if damaged, misused or overloaded. Inspect before use. Use by untrained personnel is hazardous. Observe and do not exceed Work Load Limits. DEATH and INJURY can occur from improper use or maintenance. Refer to the following for Important Safety, Use and Inspection Information. Safety Information and Inspection & Removal.

|

|

| Sling Inspection |

Avoid using adjustable rope slings that show signs of aging and wear. If there is any doubt, do not use the sling; remove it from service for evaluation. No visual inspection can accurately determine the residual strength of the sling. Inspect prior to each use for frayed strands and broken yarns. A pulled strand can snag during use. Both outer and inner rope fibers contribute to the strength of the rope. When either is worn, the rope is weakened. Heavy use will cause the rope to be compacted or hard. This is an indication that the tensile strength and the dielectric strength of the rope have been reduced. UV degradation is indicated by discoloration and the presence of splinters and slivers on the rope surface.

REMOVAL FROM SERVICE CRITERIA

ASME B30.9-2003 Removal Criteria 9-4.9.4

A synthetic rope sling shall be removed from service if conditions such as the following are present:

-

Missing or illegible sling identification

-

Cuts, gouges, areas of extensive fiber breakage along length, and abraded areas on the rope

-

Damage that is estimated to have reduced the effective diameter of the rope by more than 10%

-

Uniform fiber breakage along the major part of the length of the rope in the sling such that the entire rope appears covered with fuzz or whiskers

-

Inside the rope, fiber breakage, fused or melted fiber (observed by prying or twisting to open the strands) involving damage estimated at 10% of the fiber in any strand or the rope as a whole

-

Discoloration, brittle fibers, and hard of stiff areas that may indicate chemical damage, ultraviolet light damage or heat damage

-

Dirt and grime in the interior of the rope structure that is deemed excessive

-

Foreign matter that has permeated the rope and makes it difficult to handle and may attract and hold grit

-

Kinks and distortion in the rope structure, particularly if caused by forcibly pulling on loops (known as hockles)

-

Melted, hard or charred areas that affect more than 10% of the diameter of the rope or affect several adjacent strands along the length that affect more than 10% of strand diameters

-

Poor condition of thimbles or other components manifested by corrosion, cracks, distortion, sharp edges, or localized wear

-

Other visible damage that causes doubt as to the strength of the sling

|

|

|

| |

Can fail if damaged, misused or overloaded. Inspect before use. Use by untrained personnel is hazardous. Observe and do not exceed work load limit. DEATH or INJURY can occur from improper use or maintenance.

DO NOT EXCEED WORK LOAD LIMITS.

|

|

|

|

|

|

| Adjustable Rope Slings: Inspection, Damage Examples & Removal From Service Criteria |

|

Adjustable Rope Sling users shall be trained in the selection, inspection, cautions to personnel, environmental considerations and rigging practices. Be sure to read and understand information that accompanies the sling and is contained in this publication. Refer to information on mechanical and environmental considerations. Use by untrained persons may result in INJURY or DEATH.

Adjustable Rope Slings must be protected from damage by materials of sufficient strength, thickness and construction. Refer to Sling Info Sheet for sling protection information.

Inspect prior to use for frayed strands and broken yarns. A pulled strand can snag during use. Do not use Adjustable Rope Slings that appear to be damaged. If there is any doubt, do not use the sling; remove it from service for evaluation. Refer to Web Sling Inspection for information on Sling Inspection Systems. Be sure to employ all three levels of inspection: Initial, Frequent and Periodic. No visual inspection can accurately determine the residual strength of the sling

.

Both outer and inner rope fibers contribute to the strength of Adjustable Rope Slings. When either is worn, Adjustable Rope Slings are weakened. Heavy use will cause the rope to be compacted or hard. This is an indication that rope tensile strength has been reduced.

UV degradation is indicated by discoloration and the presence of splinters and slivers on the rope surface.

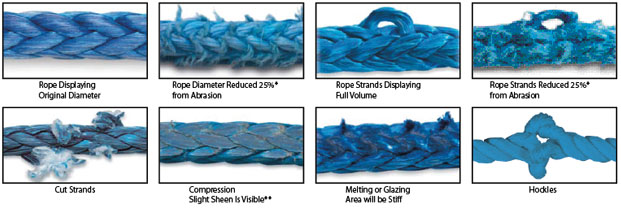

Sling Damage Examples

If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only. If any damage such as the following is visible, the sling shall be removed from service immediately. Photos depict examples of sling damage, but note they are extreme examples provided for illustration purposes only.

* 10% is cause for removal from service **Don’t confuse compression with heat damage.

Removal From Service Criteria

Synthetic rope slings shall be removed from service if conditions such as the following are present:

- Missing or illegible sling identification. Identification content for rope sling tags is identical to web sling tag requirements.

- Cuts, gouges, areas of extensive fiber breakage along the length and abraded areas on the rope.

- Damage that is estimated to have reduced the effective diameter of the rope by more than 10%.

- Uniform fiber breakage along the major part of the length of the rope in the sling such that the entire rope appears covered with fuzz or whiskers.

- Inside the rope, fiber breakage, fused or melted fiber (observed by prying or twisting to open the strands) involving damage estimated at 10% of the fiber in any strand or the rope as a whole.

- Discoloration, brittle fibers and hard of stiff areas that may indicate chemical damage, ultraviolet light damage or heat damage.

- Dirt and grime in the interior of the rope structure that is deemed excessive.

- Foreign matter that has permeated the rope and makes it difficult to handle and may attract and hold grit.

- Kinks and distortion in the rope structure, particularly if caused by forcibly pulling on loops (known as hockles).

- Melted, hard or charred areas that affect more than 10% of the diameter of the rope or affect several adjacent strands along the length that affect more than 10% of strand diameters.

- Poor condition of thimbles or other components manifested by corrosion, cracks, distortion, sharp edges or localized wear.

- For hooks, removal criteria as stated in ASME B30.10.

- For rigging hardware, removal criteria as stated in ASME B30.26.

- Other visible damage that causes doubt as to the strength of the sling.

|

|

|